The Role of Multi Blade Saws in High-Volume Flooring Production

Modern flooring manufacturers face intense pressure to boost output while cutting costs and waste. In a typical wood flooring production line, massive panels or planks must be cut into narrow strips quickly and precisely. Multi‑blade (multi‑rip) saws have emerged as a critical solution for these challenges. By slicing entire boards into multiple flooring strips in one pass, multi‑blade saws dramatically increase throughput and consistency. This article explores how these high‑speed flooring cutting machines fit into the production process, their benefits, and why advanced models like HENGDA®’s machines are gaining favor in large‑scale flooring plants.

Integrating Multi Blade Saws into the Flooring Production Process

Multi‑blade saws are typically used at the dividing stage of a flooring line. For example, in engineered or laminate flooring production, large HDF/MDF panels are first trimmed on a dividing line. After coating, these panels are then ripped into individual flooring planks by multi‑blade saws. A multi blade flooring rip saw (also called a flooring rip saw machine or plank saw machine) uses several blades on one shaft to split a panel into exact‑width strips in a single pass.

Key Benefits of Multi Blade Saws for Flooring Manufacturers

Adopting multi‑blade saws in a flooring line delivers clear advantages:

- Higher Throughput: Cutting multiple boards in one pass slashes production time. A multi blade rip saw “allows manufacturers to cut multiple strips in a single pass, dramatically increasing daily output”. This high-speed slicing means plants can process far more wood per shift compared to single-blade saws.

- Precision & Consistency: Industrial saws use servo‑controlled blade adjustment and rigid frames to maintain uniform width. HENGDA saws achieve tight tolerances (around ±0.2 mm) on each cut, ensuring every flooring plank is consistent. Consistent cuts also smooth out downstream processes like profiling and finishing.

- Reduced Material Waste: Precise kerf control and optimized cutting layouts mean less scrap. Multi‑blade rip saws maximize board utilization by planning cuts that minimize offcuts. In practice, manufacturers see significantly lower raw material costs when using these saws.

- Automation Compatibility: These machines fit neatly into automated production. Fully automatic loading/unloading systems and conveyors replace manual handling. Operators simply load panels; the system feeds, cuts, and unloads them via sensor‑controlled rollers. This not only boosts speed but also improves safety (enclosed saws, anti‑kickback features) while cutting labor costs.

- Flexibility for Custom Runs: Multi‑blade saws handle both large batches and small custom orders. Variable-frequency drives adjust feed speed for different board sizes, and some models offer dual spindles for simultaneous cutting and slotting. This flexibility lets flooring producers switch quickly between product lines without lengthy changeovers.

In short, multi blade saws form the high-speed flooring cutting equipment at the heart of many modern wood flooring production lines. As one industry report notes, “high efficiency, precision and stability, reduced waste, and flexible integration” are all key advantages of these machines. Flooring manufacturers that integrate multi‑blade saws routinely achieve faster output and higher product consistency.

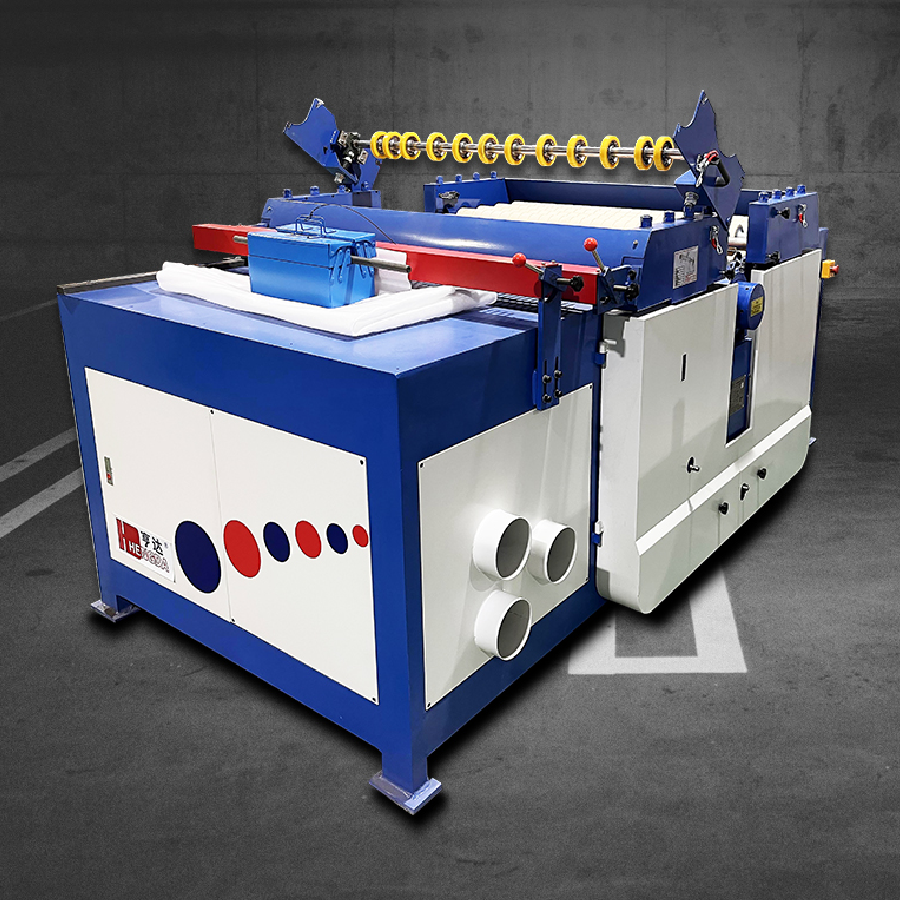

HENGDA Multi Blade Saw Solutions for Flooring Production

HENGDA’s multi‑blade rip saws are engineered for the specific demands of large-scale flooring production. These heavy-duty machines offer models tuned for different board thicknesses and feed capacities. Key HENGDA features include:

- High-Speed Feeding: HENGDA saws use inverter-controlled conveyors to feed boards at speeds up to 17 m/min. This rapid material handling keeps the cutting zone busy and maximizes throughput in a high-speed flooring cutting equipment setup.

- Durable Construction: Every HENGDA machine is built on a precision-machined steel frame and fitted with wear-resistant nitrile rubber rollers. Reinforced feeding conveyors and heavy-duty components (e.g. ductile-iron bearings) enable continuous 24/7 operation with minimal maintenance. This rugged design ensures long machine life even under the heavy loads of a busy flooring saw line.

- Blade Precision: The saw units (spindles) are balanced for stability and feature safety enclosures. Operators can expect extremely tight cut tolerances (±0.2 mm) even on thick panels. Models like the HD1300-XT2L even offer a dual-spindle option, adding a top blade for simultaneous slotting and cutting to save production steps.

- Automation-Ready Operation: HENGDA machines integrate seamlessly into automatic lines. Their cutting stations come with photoelectric sensors and synchronized rollers for hands-free feed. Fully automatic loading/unloading systems eliminate the need for manual handling. The result is a true automatic flooring saw line where raw panels enter one end and precisely cut floorboards emerge at the other.

- Advanced Safety & Controls: Operator safety is built in. All saws have interlocked protective covers and anti-rebound grips to prevent kickback. Intelligent controls and optional servo systems further ensure each slice is accurate. These features collectively give manufacturers a competitive edge in both productivity and workplace safety.

Real-World Impact for Flooring Producers

Flooring manufacturers who adopt multi-blade saw lines report dramatic improvements. As industry experts note, “furniture makers, flooring manufacturers, and packaging companies alike can realize significant improvements in output and profitability by integrating these powerful machines”. In other words, any high-volume wood processing operation stands to gain from multi-rip technology.

For example, a flooring plant that upgrades from manual cross-cutting to a HENGDA automated saw line can see throughput jump while reducing labor inputs. The combined gains in speed, consistency and waste reduction translate directly to higher margins on each board. With global demand for quality flooring steadily rising, these productivity boosts are no longer optional – they’re essential.

In summary, multi blade saws are a foundational component of efficient, large-scale flooring production. By slicing panels into precision planks at high speed, they address key industry challenges of throughput, consistency, and material use. Advanced systems like HENGDA’s HD1300 series take this even further with robust 24/7 designs, tight cut tolerances, and full automation compatibility

Conclusion

To stay competitive, flooring manufacturers must equip their production lines with high-performance cutting equipment. HENGDA’s automatic multi blade saw production lines offer turnkey solutions for this need. These systems are “designed for continuous, high-volume production” and have fully automatic loading/unloading and intelligent material handling, giving manufacturers a measurable productivity edge.

Don’t let manual sawing become your bottleneck. Contact HENGDA today to discuss a custom multi-blade saw line tailored to your flooring operation. With HENGDA’s expertise and proven multi saw series machines, you can maximize output, quality and ROI on your wood flooring production line. Boost your throughput and efficiency—reach out to HENGDA for a consultation and step into the future of flooring manufacturing.