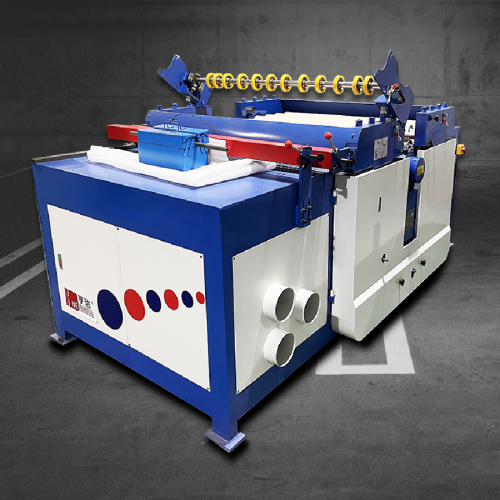

High Efficiency Automatic Loading & Unloading Multi Blade Rip Saw Production Line For Wood Panel

Hengda’s automatic loading/unloading multi blade rip saw production line significantly improves wood panel processing. This wood panel cutting production line automates material handling, increases processing speed, and reduces labor with features like automatic loading/unloading, scraper-type feeding, and a user-friendly interface. Ideal for door, furniture, and floor manufacturers.