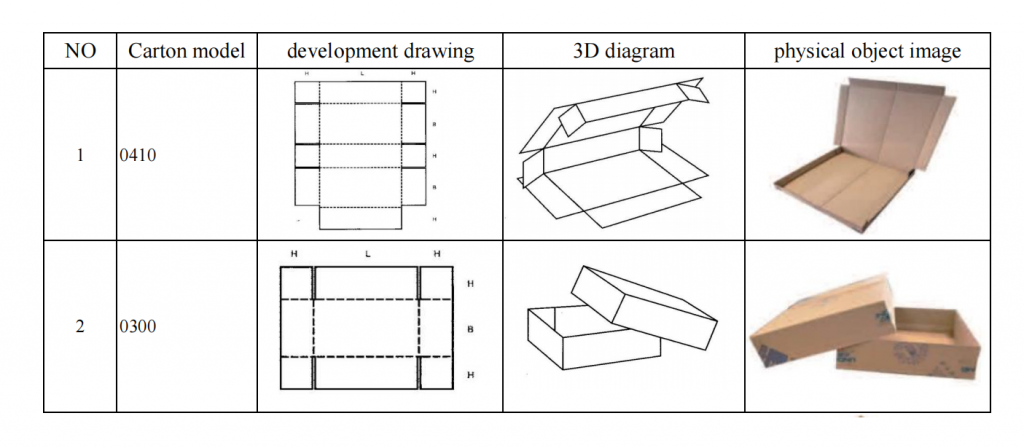

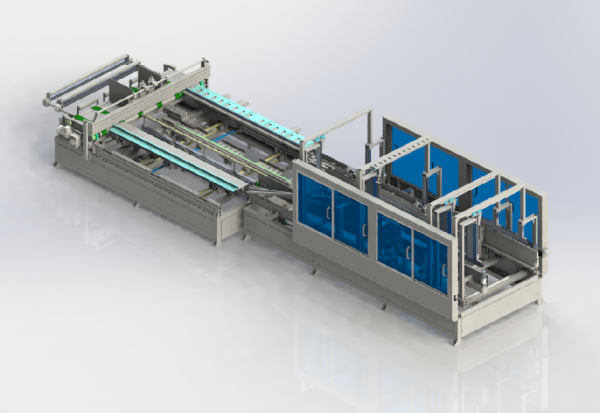

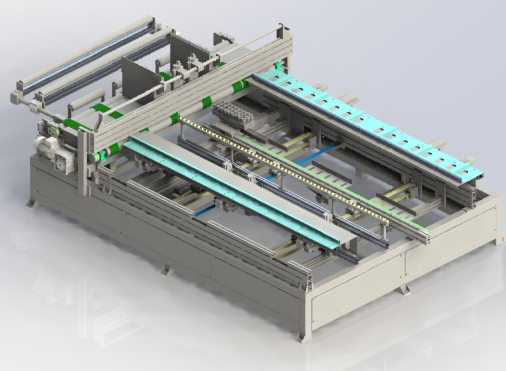

MZH2509-D Automatic Flexible Carton Folding Machine for Bottom Box Forming

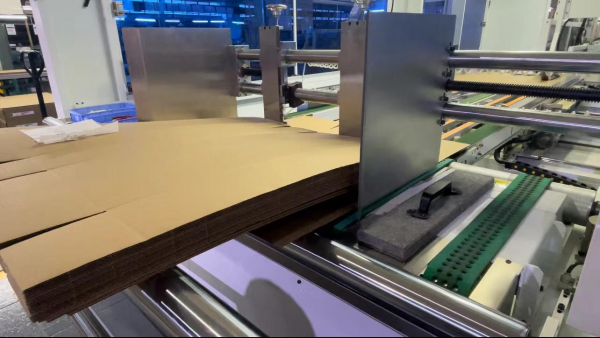

The MZH2509-D Automatic Carton Folding Machine is designed for bottom box forming of single-cover and top-bottom lid cartons.

It features automatic feeding and EVA hot melt gluing, ensuring strong, clean, and consistent carton bases. Perfect for customized packaging lines to improve efficiency and save labor.