Optimizing Your MDF Cutting Production Line: A Comprehensive Guide

In today’s fast-paced woodworking industry, a high-efficiency MDF cutting production line is crucial for meeting large-scale demand while maintaining precision and minimizing waste. Whether you manufacture furniture, cabinetry, or engineered wood flooring, a well-designed multi-blade MDF saw line can transform your operations. This article explains the key components, technical features, workflow, and best practices for a top-performing MDF cutting line—and shows you how to leverage these systems to boost throughput, quality, and profitability.

Why Invest in an MDF Cutting Production Line?

- Scale & Speed: Modern factories process thousands of square meters of MDF daily. Traditional single-blade saws become bottlenecks—panel multi-blade rip saws can slice entire sheets into strips in one pass.

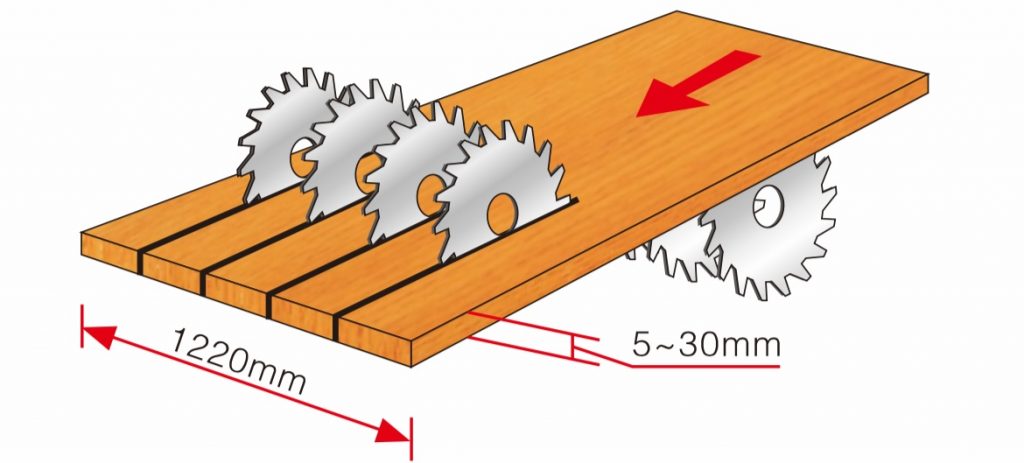

- Precision & Consistency: Engineered products demand tight tolerances. A multi-blade MDF saw machine equipped with precision‐control delivers uniform strip widths (±0.1 mm), ensuring perfect downstream profiling and finishing.

- Material Yield: By optimizing blade spacing and reducing kerf loss, MDF board slitting machines maximize usable material, cutting scrap by up to 30%.

- Labor & Safety: Automated panel cutting lines with PLC‐driven conveyors and interlocked guards reduce manual handling, lower labor costs, and enhance operator safety.

Core Components of a High-Efficiency MDF Cutting Line

Automatic Feeding System

- Scraper Feeding Device: Push the panel one by one from the stacking panels to the roller conveyor line.

- Hydraulic Lifting Table: Automatic lifting or lowering according to the height of the stacking panels.

- Roller Conveyor Line: Conveying the panels and maintain straight side-by-side feed by alignment device.

- Photoelectric Sensors: Trigger infeed and downstream transfers, synchronizing the entire line.

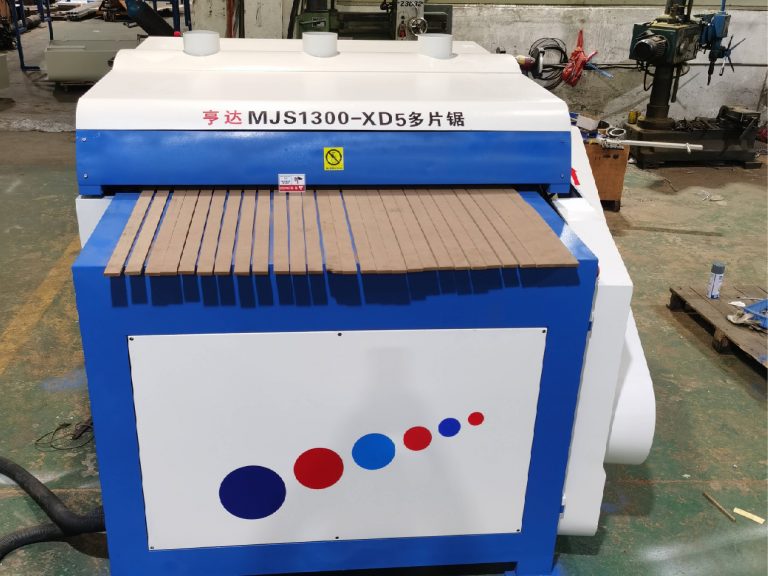

Multi-Blade Rip Saw Unit

- Optional Rip Saw Unit: Different models of saw machine can be matched with the line, meeting different cutting demands and raw material sizes.

- Fixed Spindle Design: Blades and spacers stack on a single shaft and can be adjusted according to the processing width.

- High-Speed Spindles: 3,000–4,000 RPM NSK bearings ensure minimal run-out and smooth cuts.

- Enclosed Safety Covers: Interlocked guards shut off power if opened, protecting operators.

Slotting & Cross-Cut Modules (Optional)

- Grooving Stations: Insert decorative or joint grooves in one pass.

- Transverse Rip Unit: Cross-cuts strips to length without manual reloading.

Dust Collection & Safety Systems

- High-CFM Extraction Ports: ≥1,000 CFM collectors keep debris away from blades and bearings.

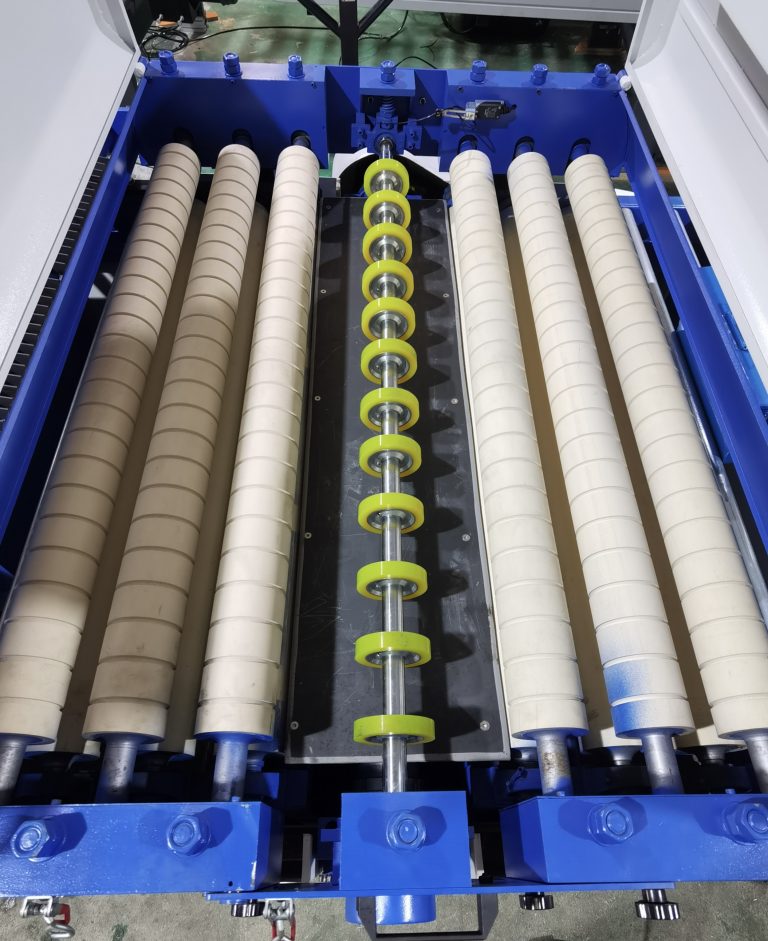

- Anti-Kickback Fingers & Hold-Down Rollers: Prevent board rebound and ensure stable feeding.

Central PLC Control

- PLC Touchscreen: Operators control the MDF cutting line via PLC touchscreen.

- Real-Time Monitoring: Fault detection, cycle counts, and maintenance alerts improve uptime.

Workflow: From Sheet to Strips

- Loading: Operators place the MDF sheets onto the hydraulic lifting table by forklift.

- Alignment: Side-stepping guides square each sheet.

- Longitudinal Rip: The multi-blade saw rips the sheet into 4–8 strips in one pass.

- Unloading: Photoelectric sensors trigger end-of-line conveyors or stackers to collect finished strips.

Best-Practice Recommendations

- Blade Selection & Maintenance

- Use the suitable blades rated for MDF with our advice.

- Sharpen or replace blades before kerf increases by >0.2 mm.

- Roller Care

- Replace worn rubber sleeves every 6–12 months to maintain grip.

- Dust Management

- Match dust collector capacity to line CFM; clean filters weekly.

- Routine Calibration

- Check spindle alignment, feed roller tension, and PLC parameters monthly.

Conclusion & Next Steps

An MDF cutting production line built around a multi-blade rip saw machine is a game-changer for high-volume panel processing. By combining precision, speed, and automation, this line help manufacturers meet tight deadlines, maintain quality, and reduce costs.

Ready to upgrade your production? Contact us today for a custom line design and see how our solutions can maximize your MDF panel throughput and profitability.