Integrating the MZH2509-D Carton Forming Machine with an Automatic Sealing Line

In the modern factory, the demand for automation, efficiency, and flexibility is greater than ever.

Manufacturers are no longer satisfied with single-purpose machines — they pay attention to the packaging aspect, looking for a complete packaging line that can reduce labor dependence, improve speed, and ensure consistent product quality.

The integration of Hengda MZH2509-D Flexible Carton Forming Machine with an automatic sealing line represents a new generation of intelligent packaging solutions, designed to transform how cartons are formed, filled, and sealed.

The Rising Demand for Intelligent Packaging Line

Traditional carton forming and sealing operations often rely on manual labor. Workers fold the box bottoms, apply glue, load products, and finally seal the tops. This approach is slow, inconsistent, and difficult to scale. As product package demand is becoming higher, manual packaging could not meet the standard. And manual packaging may lead to low efficiency as well.

At the same time, global competition and labor costs are driving manufacturers to optimize productivity and reduce operational costs. Smart packaging automation is not just a trend; it is now a fundamental requirement for sustainable manufacturing and long-term competitiveness.

The Core of MZH2509-D Flexible Carton Forming Machine

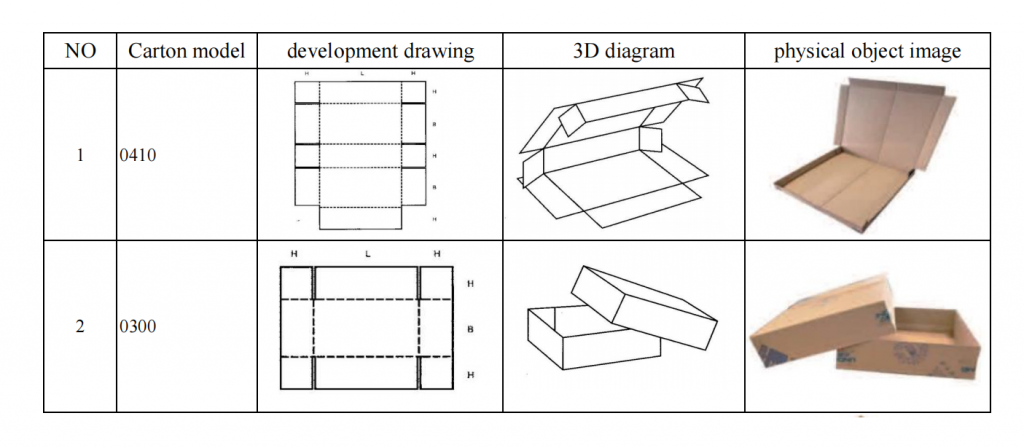

At the heart of this intelligent line is the MZH2509-D Flexible Carton Forming Machine. This machine specializes in forming the bottoms of 0410 and 0300 box types — including single-cover and top-and-bottom lid cartons — automatically and precisely.

It features an automatic feeding system, allowing operators to stack multiple corrugated sheets for continuous production. Each sheet is automatically aligned and positioned through an auto-correction mechanism, ensuring accurate folding before gluing. The EVA hot melt adhesive system bonds the four corners of the carton, creating a firm, clean, and beautifully shaped base ready for product loading.

Thanks to its servo-controlled width adjustment, the MZH2509-D can quickly switch between different carton sizes, making it ideal for short-run, multi-size, and customized packaging production. Its heavy-duty steel structure and 10-inch touchscreen PLC interface combine reliability with user-friendly control, ensuring stable, long-term operation in demanding industrial environments.

Integration with the Automatic Sealing Machine

Once the carton base is formed, it moves to the next stage — product loading and top sealing.

After the items are placed inside, the automatic carton sealing machine takes over, applying hot melt glue to the top flaps and pressing them firmly into place.

The result is a smooth, tightly sealed box with consistent quality across every unit.

Together, the two machines form a “Carton Forming + Sealing” integrated packaging line, capable of operating continuously with minimal manual intervention.

This intelligent linkage eliminates idle time between processes and maintains perfect coordination between forming, loading, and sealing.

The Advantages of a Combined Packaging Line

Continuous and High-Speed Operation

The integration allows both machines to operate synchronously, achieving 5–10 times higher output than manual lines. Cartons move seamlessly from forming to sealing, minimizing downtime and maximizing throughput.

Reduced Labor and Operational Costs

Instead of multiple workers handling each stage, only one or two operators are needed to supervise the box forming and sealing process. This reduces labor dependency, training costs, and the risk of production delays caused by staff shortages.

Consistent and Aesthetic Packaging Results

Automatic folding and sealing ensure every carton has the same shape, alignment, and strength.

The finished boxes have a “cube-like” appearance — clean, symmetrical, and ready for branding or logistics.

Fast Changeovers for Flexible Production

Servo-driven adjustments enable rapid switching between box sizes, ideal for short-batch or diversified production. This flexibility helps factories handle multiple orders simultaneously without sacrificing efficiency.

Eco-Friendly and Clean Gluing Process

The use of EVA hot melt adhesive offers strong bonding with minimal waste or fumes.

It aligns with modern green manufacturing standards, ensuring cleaner working conditions and environmentally responsible production.

Real-World Applications

The integrated carton forming and sealing line is widely adopted across multiple industries, including:

- Furniture and home appliances – for large, sturdy boxes requiring strong bottom sealing.

- E-commerce fulfillment centers – handling varied box sizes with fast turnaround.

- Custom packaging workshops – supporting small orders and frequent size adjustments.

In every case, the system enables businesses to increase packaging speed, improve consistency, and reduce production costs while maintaining flexibility.

The Path to Smart Factory Automation

Integrating the MZH2509-D with an automatic sealing line is not just an equipment upgrade — it’s a strategic move toward intelligent packaging automation. By connecting forming, filling, and sealing into one continuous process, manufacturers gain full control over packaging quality, efficiency, and cost structure.

It’s a solution that reflects the future of packaging — where automation replaces manual labor, data ensures consistency, and flexibility meets customization. For manufacturers aiming to modernize their operations, this integration is the first step toward building a truly smart packaging factory.