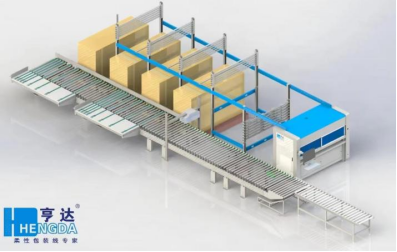

Hengda Intelligent Packaging Solution: H4A Scanning Integrated Line

In today’s manufacturing landscape, where demands for efficiency, precision, and flexibility are increasingly stringent, intelligent packaging solutions have become critical for enhancing core competitiveness. Leveraging its deep expertise and forward-thinking vision in flexible packaging, Hengda proudly presents the H4A Scanning Integrated Line—an innovative smart packaging system designed to meet market needs while integrating multiple advantages. This solution not only optimizes traditional packaging processes but also elevates production capabilities to new heights, helping customers thrive in a competitive market.

A Compact, High-Efficiency System For Intelligent Packaging

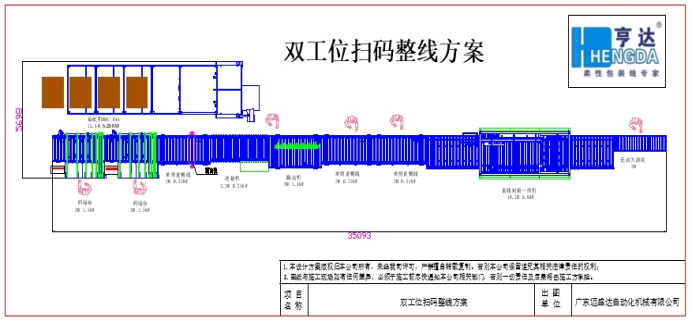

The H4A Dual-Station Scanning Integrated Line is meticulously designed for medium-to-high-capacity manufacturers.

High Production Capacity

- Supports 15,000–25,000㎡ monthly output (unfolded area).

- Requires only 5–6 operators, significantly reducing labor costs. Optimized Labor Efficiency

- Footprint: 35m × 6m, ideal for facilities with limited space. Space-Saving Design

Precision, Efficiency & Intelligence of Intelligent Packaging

Ultra-Precise Measurement, Eliminating Errors

- Advanced height sensors replace manual layer counting, ensuring real-time, accurate height data.

- Through scanning each QR code on the panel and generate an outer package code which includes size information.

- Guarantees perfectly matched cuts, minimizing material waste and defective packaging.

Independent Servo Control for Faster Cutting

- Cutting tools feature servo-driven precision, enhancing speed and accuracy.

- Boosts cutting efficiency while maintaining stability at high speeds.

Automated Sealing for “Neat Block Packaging”

- Achieves industry-standard “neat block” packaging—uniform, stackable, and visually appealing.

- Improves stacking stability, reducing damage risks during storage and transit.

System Components: Seamless Automation

| Equipment | Qty | Function |

|---|---|---|

| MAC-H4 Carton Machine | 1 | 4-paper-silo |

| MP-MDT Palletizing Stations | 2 | Panel item handling |

| MP-GT Roller Conveyors | 3 | Smooth inter-station transfer |

| Height Sensor | 1 | Precise height measurement |

| MP-SX Carton Feeder | 1 | Automated carton delivery |

| MP-FG Lid-Flipper | 1 | Prepares cartons for sealing |

| FXZB-R2812 Sealing Machine | 1 | Automated final sealing |

| MP-WGT Buffer Rollers | 1 | Flexible material handling |

| PLC Control System | 1 | Centralized smart control |

| Customer-Supplied | 1 set | PLCs, scanners, label printers |

Conclusion: A Strategic Leap Toward Smart Manufacturing

The H4A Scanning Integrated Line is more than just automation—it embodies Hengda’s commitment to flexible, intelligent packaging innovation. By adopting this solution, manufacturers can:

- Reduce labor costs

- Maximize material utilization

- Enhance packaging quality & brand appeal

Choosing Hengda means securing a competitive edge—where superior packaging, faster delivery, and lower operational costs drive market success. This is your definitive step toward smart manufacturing and sustainable growth.