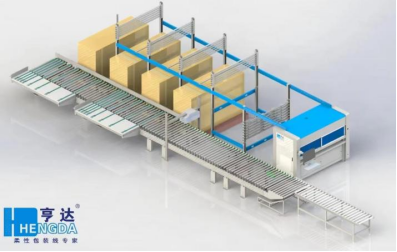

Hengda Intelligent Packaging Line: H4A Dual-Workstation With Scanning System

In the flexible production of custom cabinetry and custom home furnishing industries, where multi-specification, small-batch orders present challenges, intelligent and precise packaging solutions become crucial. Hengda presents the H4A Dual-Wokstation Carton Packaging Line With Scanning System – a highly integrated, cost-effective solution that excels in free packing mode, combining advanced system with intelligent carton cutting machine coordination for precise packaging dimensioning.

Overview Of The Packaging Line

The H4A Dual-Workstation Solution delivers exceptional packaging automation with:

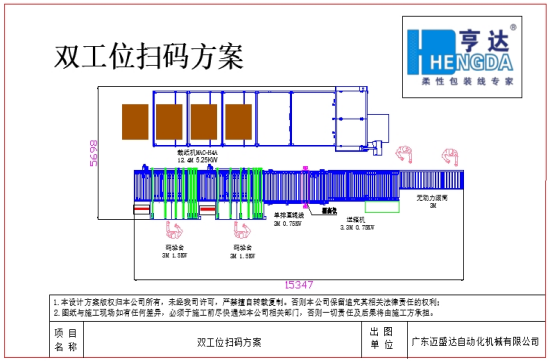

Compact Footprint

- 15m × 6m layout, ideal for space-constrained facilities

Cost-Effective Automation

- Balances performance and affordability

- 3-4 operators required, reducing labor costs

Optimized for Medium-Scale Production

- Supports 10,000–20,000㎡ monthly output (unfolded area)

Precision Dimensioning

- Integrated height sensor replaces manual layer counting

- Delivers more reliable data than traditional estimation methods

Precise Dimension Capture in Free Packing Mode

The system ensures accurate packaging sizing through smart data acquisition and carton cutting machine synchronization:

QR Code-Based Dimension Chain

- Single-Panel QR Scanning

- Scans QR codes on individual panels to extract attributes & dimensions

- Master Packaging QR Generation

- System consolidates panel data to create an overall package QR code

- Height Measurement Logic

- If QR contains L/W/H: Industrial camera verifies dimensions

- If height missing: Height sensor provides real-time measurement

Industrial Camera’s Critical Role

With multiple palletizing stations and unpredictable package sequencing, the camera:

- Identifies packages via QR/visual recognition

- Triggers dynamic cutting – the system auto-adjusts the cutter to produce perfectly sized packaging, minimizing material waste

Equipment List Of The Packaging Line

| Component | Qty | Key Function |

|---|---|---|

| MAC-H4A Carton Machine | 1 | 4-cardboard-silo |

| MP-MDT Palletizing Stations | 2 | Panel stacking/loading |

| MP-GT Straight Roller Conveyor | 1 | Material transport |

| Height Sensor | 1 | Height Measuring |

| Industrial Camera | 1 | Package identification |

| MP-SX Carton Feeder | 1 | Precision carton delivery |

| MP-WGT Non-Powered Rollers | 1 | Buffer/transfer assist |

| PLC Control System | 1 | Centralized automation control |

| Customer-Supplied | 2 sets | PCs, scanners, label printers |

Conclusion

The H4A Dual-Workstation Solution redefines flexible packaging with:

Smart QR-based dimensioning

Real-time carton cutting machine coordination

Material-optimized packaging

Ideal for manufacturers seeking agile, automated packaging without compromising precision or cost-efficiency.