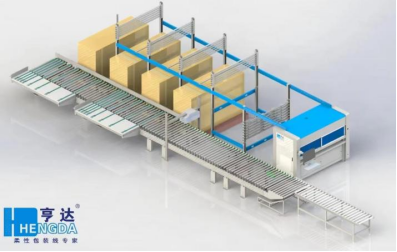

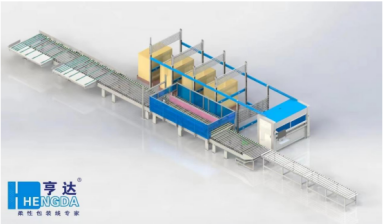

Hengda Intelligent Packaging Line: Customized Integration Solutions

In the era of smart manufacturing, flexibility and precision are key competitive advantages. Hengda, a leader in intelligent packaging solutions, understands the diverse needs of factories with different production models and scales. We offer customized packaging line integration solutions and multiple panel dimension data acquisition methods to ensure accurate and efficient data flow, helping factories transition to intelligent production.

Multiple Methods for Panel Dimension Data Acquisition

Accurate panel dimension data is the foundation of an efficient automated packaging system. We provides multiple data acquisition solutions to meet varying customer needs in precision, speed, and cost:

Industrial Cameras & Height Sensors (Direct Measurement)

- Industrial cameras capture panel IDs, QR codes, length, width, and height with high precision.

- Height sensors provide exact thickness measurements.

- These devices can be flexibly installed at key production line points for real-time dimension data.

Professional Measuring Stations (For Higher Precision & Speed)

When higher accuracy, processing speed, or system integration is required, our measuring stations excel:

- Precision Measuring Station (Single/Dual-Station)

- ±1mm accuracy for high-precision applications.

- Length/Width Synchronous Measuring Station (Dual-Station)

- Measures length and width simultaneously (±1mm accuracy).

- Light Curtain Measuring Station

- ±2.5mm accuracy, ideal for high-throughput applications where slight tolerance is acceptable.

These measuring stations can be combined with cameras and height sensors for a comprehensive data collection system.

Hengda Packaging Line Integration: Three Factory Types

We categorize factories into Type A, B, and C based on production organization, IT infrastructure, and specific needs, offering tailored solutions for each:

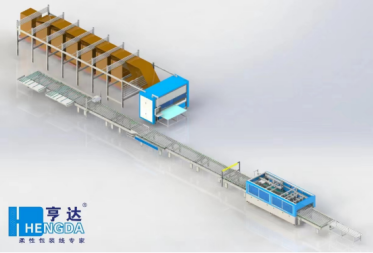

Type A: MES-Driven Pre-Sorting & Sub-Packaging Solution

- Key Feature: Deep integration with MES (Manufacturing Execution System) for optimized material flow.

- Dimension Data Acquisition:

- Industrial cameras (ID, QR code, L/W/H) + height sensors.

- Pre-Sorting & Sub-Packaging Options:

- Bookshelf-style sorting racks (high efficiency, higher cost).

- 3D flat sorting racks (space-saving, automated).

- Traditional flat sorting (larger footprint) or manual bookshelf sorting (flexible transition option).

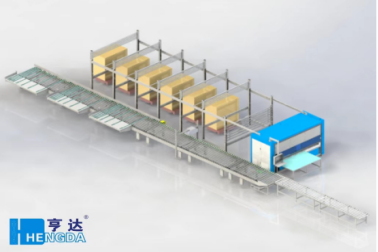

Type B: ERP-Driven Hybrid Solution (Pre-Sorting + Free Packing)

- Key Feature: Balances pre-sorted packaging (fixed pallets) and free packing (flexible stacking).

- Dimension Data Acquisition:

- Free packing: Real-time dimension capture via cameras + sensors.

- Measuring Stations (Optional):

- Precision (±1mm) or Light Curtain (±2.5mm) stations for enhanced data accuracy.

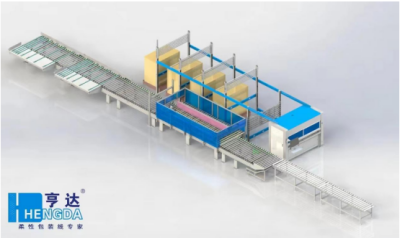

Type C: BOM-Driven Free Packing Solution

- Key Feature: Uses cutting order software (BOM import) for fully flexible free packing.

- Dimension Data Acquisition:

- Cameras + height sensors during free packing.

- Measuring Stations (Optional):

- Dual-station precision (±1mm) or light curtain (±2.5mm) stations for efficiency.

Conclusion

Hengda’s intelligent packaging solutions stand out due to their flexibility and customization. By offering multiple dimension data acquisition methods (cameras, sensors, measuring stations) and tailored integration strategies for Type A, B, and C factories, we ensure every customer gets the most efficient, cost-effective, and future-ready packaging system.