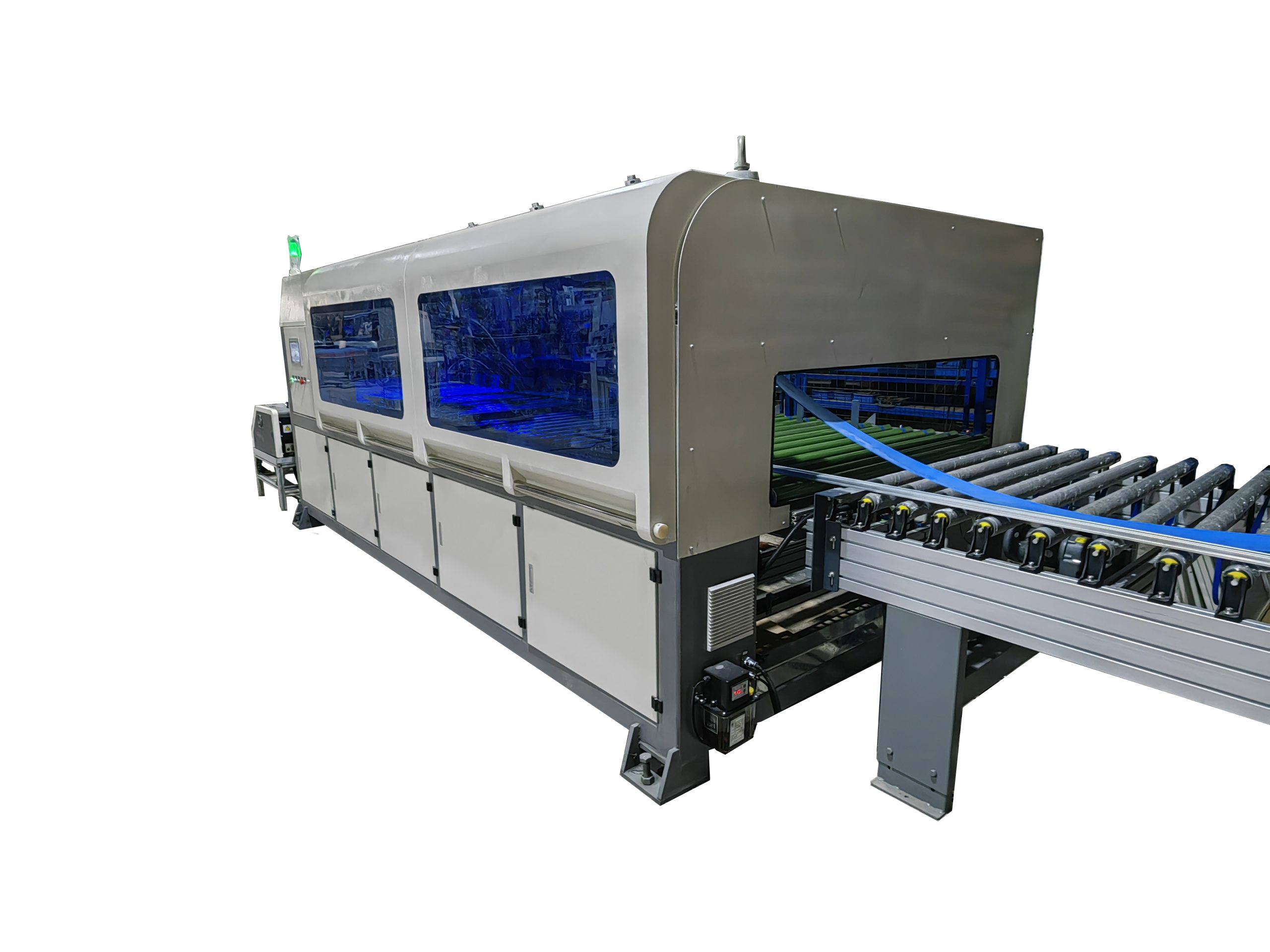

Hengda Intelligent Packaging Line: MP-ATFX Automatic Box Sealing Machine

At the final stage of the intelligent packaging line, the box sealing process is crucial for ensuring product safety and packaging aesthetics. As a key component of Hengda’s intelligent packaging solutions, the MP-ATFX automatic box sealing machine delivers fast, secure, and visually clean sealing for specific box types through advanced EVA glue technology and high-efficiency automation.

Overview of MP-ATFX Automatic Box Sealing Machine

The MP-ATFX is a high-performance machine designed by us for automated case sealing. Playing a pivotal role in the intelligent packaging line, it ensures that precisely measured and cut cartons are quickly and perfectly sealed, preparing them for subsequent logistics and storage.

Core Technology and Key Features For Box Sealing Machine

Precision EVA Glue Application & Pressure-Sealed Bonding:

- The MP-ATFX utilizes an advanced EVA glue system to accurately apply adhesive to carton edges.

- After glue application, the machine applies controlled pressure to ensure deep penetration and strong bonding, resulting in reliable sealing.

- EVA glue offers superior adhesion, rapid curing, and environmental friendliness, enhancing carton durability and sealing performance even in demanding transport conditions.

High-Efficiency Automated Glue Sealing:

- The machine automates the entire glue sealing process, replacing traditional manual gluing and folding.

- Precision-controlled operations minimize human intervention, reduce errors, and ensure consistent, aesthetically pleasing seals.

Compatibility with Specific Box Types & Sizes:

- Currently, the MP-ATFX is optimized exclusively for M410-style cartons within the following dimensional range:

- Length (L): 300mm to 2400mm

- Width (W): 400mm to 1150mm

- Height (H): 10mm to 250mm

- This targeted compatibility maximizes performance for M410 carton production.

Impressive Operational Speed:

- While maintaining sealing quality, the MP-ATFX achieves remarkable efficiency:

- For M410 cartons under 1200mm in length, sealing speed reaches ~8 seconds per package, significantly boosting production throughput.

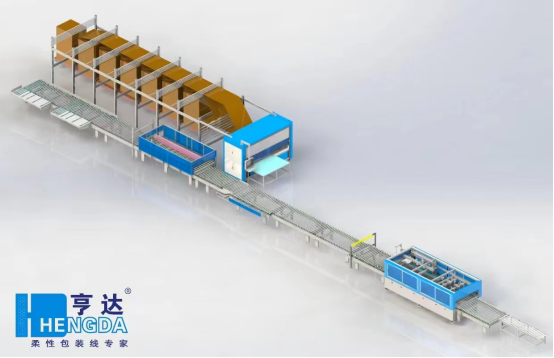

Seamless Integration with the Packaging Line

The MP-ATFX seamlessly synchronizes with other our intelligent packaging equipment:

- Upstream Integration: Works in tandem with corrugated carton cutters and folding machines, receiving pre-folded M410 cartons for immediate sealing.

- Downstream Connectivity: Sealed packages proceed directly to conveyors or palletizing systems, ensuring a smooth, fully automated workflow.

- This high-level integration minimizes manual handling and delays, enhancing overall line efficiency.

Key Benefits of Box Sealing Machine

Deploying the MP-ATFX delivers significant advantages for M410 carton users:

- Enhanced Sealing Efficiency: Automation drastically reduces packaging cycle times.

- Lower Labor Costs: Reduced reliance on manual labor cuts operational expenses.

- Consistent Seal Quality: Precision EVA application guarantees uniform, robust, and visually appealing seals.

- Improved Product Protection: Superior sealing shields contents from dust, moisture, and physical damage.

Conclusion

The Hengda MP-ATFX automatic box sealing machine is an indispensable component of the intelligent packaging line. By leveraging innovative EVA glue technology and automation, it elevates M410 carton sealing to new levels of speed, reliability, and cost-effectiveness. Choosing the MP-ATFX means adopting a smarter, more competitive sealing solution that enhances packaging quality and operational performance.