Intelligent Corrugated Carton Cutting Machine Application

In today’s dynamic market where product diversity and evolving demands are the norm, packaging has transcended its traditional role—it’s now both a product safeguard and brand differentiator. Hengda Intelligent Corrugated Carton Cutting Machine emerges as an industry game-changer, delivering unparalleled flexibility and efficiency for both bespoke customization and high-volume production needs.

Versatile Applications With Multi Packaging Demands

Our carton machine demonstrates exceptional adaptability across critical industries:

- E-commerce & Logistics: Rapidly generates dimension-specific cartons for diverse parcels, boosting packing throughput by up to 40%.

- Custom & Standardized Furniture: Ensures millimeter-perfect packaging for both unique custom pieces and mass-produced items.

- Sanitary Ware: Creates moisture-resistant, shock-absorbent tailored cartons for irregularly shaped bathroom fixtures.

- Universal Corrugated Solutions: Processes any packaging requirement with just length/width/height inputs—no specialized tooling needed.

Core Scenarios: Precision Meets Productivity

Scenario 1: Customized Furniture Packaging – The Pursuit of Precision and Individualization

In the field of customized furniture, each product is unique, so the requirements for its packaging are precise matching and individualization. Our carton machine shows great flexibility in this scenario:

Usage scenario: The need to cut precisely matched cartons for customized furniture products of different sizes and unique shapes.

Typical process:

- Palletizing panels: Furniture panels are processed and then stacked in an orderly manner.

- Carton cutting: Hengda carton machine quickly and accurately cuts corrugated cartons that perfectly match the furniture panels according to the preset customized size data.

- Foam strips, filling of hardware, etc.: subsequent manual or automated auxiliary processes ensure the stability and integrity of the product within the package.

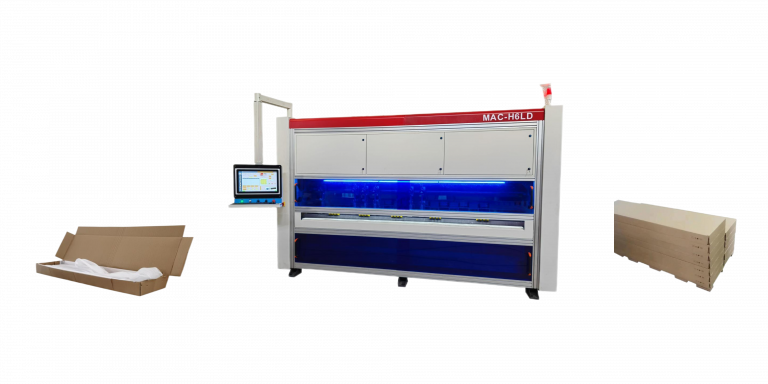

- Recommended equipment: MAC-H4A, MAC-H6A, MAC-H6L, MAC-H6LD. These models excel in handling complex customization and achieving high-precision cutting, especially the H6LD, which provides the ultimate in cutting precision and flexibility to meet high-end customization needs.

Scenario 2: Bulk Furniture Packaging – A Guarantee of Efficiency and Scale

For standardized, large-volume furniture products, the core requirements of packaging are high efficiency and consistency. Our carton machines are capable of achieving fast cutting and guaranteeing the smooth operation of production lines:

Usage scenario: Cutting large quantities of standard-sized cartons efficiently and quickly.

Typical process:

- Cutting standard-sized cartons: Hengda carton machine cut standard-sized corrugated cartons continuously and in large quantities with their high-speed, stable performance.

- Prescribed Placement of Workpieces, Foam Strips, Hardware, etc.: Pre-established placement specifications and the addition of auxiliary materials ensure consistency and efficiency in batch packaging.

- Recommended equipment: MAC-H2A, MAC-H4A, MAC-H6A, MAC-H6L These models excel in meeting the high efficiency demands of mass production, making them ideal for large-scale production lines.

Hengda Meets your differentiated needs

Whether it’s customized production with extreme requirements for dimensional accuracy or high-volume production with stringent standards for cutting efficiency, Hengda intelligent corrugated box machine offers tailor-made solutions. It ensures through automation, high precision, multi-specification processing and perfect support for continuous board:

- Production Flexibility: Easily respond to a wide range of orders from small to large quantities, from standard to customized.

- Cost-effectiveness: Reduces mold opening costs, optimizes material utilization and lowers operating costs.

- Superior quality: Ensure that each carton has accurate dimensions and neat edges, enhancing the overall image of product packaging.

Choosing Hengda means choosing an intelligent partner that empowers your packaging production. No matter what size your business is or what your needs are, we can provide you with the most suitable cutting solution to help you stay ahead of the market.