Why Every Factory Needs a Box Making Machine

In today’s competitive manufacturing world, efficiency and flexibility define success. Whether you produce furniture, electronics, or e-commerce goods, packaging remains a critical yet often overlooked part of operations. Many factories are now discovering that a box making machine is not just another piece of equipment—it is the future of smart packaging.

The Problem with Traditional Carton Procurement

For decades, factories relied on external carton suppliers and cutting cardboard box manually. At first, this seemed convenient. But as industries shifted toward customization and fast delivery, traditional carton procurement began showing cracks:

- Limited flexibility: Pre-ordered cartons rarely matched the unique sizes of custom products.

- High storage costs: Warehouses filled with unused cartons, tying up valuable space.

- Hidden waste: Oversized cartons required filler materials, increasing costs and damaging sustainability goals.

- Slow response: Any change in packaging requirements meant waiting days or weeks for suppliers.

What once worked in a mass-production era no longer suits the demands of modern, fast-changing industries.

How a Box Making Machine Changes the Game

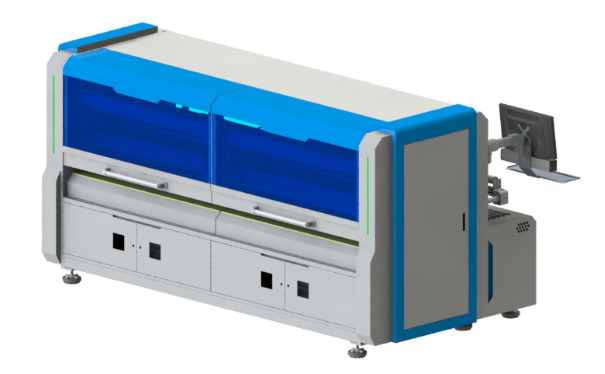

The box making machine solves these issues by allowing factories to produce cartons on demand. Instead of depending on suppliers or cutting carton by hand, manufacturers gain full control over their packaging boxes and efficiency.

Imagine finishing a custom cabinet or a small batch of e-commerce products. Instead of searching for the closest carton size, the operator enters the exact dimensions into the box making machine. Within minutes, the perfect carton is ready—efficient, precise, and cost-effective.

The Key Benefits of a Box Making Machine

1. Cost Reduction

One of the most immediate benefits of a box making machine is cost reduction. Traditional carton procurement involves bulk purchasing, which locks up cash flow and often leads to wasted materials when box sizes don’t match product dimensions. With an on-demand solution, factories only produce the cartons they need, when they need them. This eliminates over-ordering, reduces filler usage, and lowers overall packaging expenses.

2. Space Optimization

Cartons take up a surprising amount of storage. Factories that buy in bulk often dedicate entire warehouse sections to storing pre-made boxes. A box making machine changes this dynamic completely. Instead of storing hundreds of carton sizes, manufacturers can free up valuable warehouse space for raw materials or finished goods. This not only cuts storage costs but also improves workflow efficiency.

3. Unmatched Flexibility

In industries like furniture or e-commerce, product sizes vary constantly. Traditional cartons rarely provide a perfect fit, forcing compromises. With a box making machine, every carton is made to measure. Whether the order is for a single oversized wardrobe or a batch of small, delicate items, the machine delivers cartons tailored to exact specifications. This flexibility supports both small-batch production and large-scale manufacturing.

4. Sustainability and Waste Reduction

Sustainability is no longer optional; it is a core expectation of modern customers. A box making machine supports eco-friendly goals by minimizing material waste. Instead of cutting down oversized sheets of cardboard or relying on filler, the machine uses only what is necessary for each carton. This reduces carbon footprint, lowers disposal costs, and aligns factories with global green initiatives.

5. Greater Supply Chain Independence

Relying on external carton suppliers creates vulnerabilities—delays, price fluctuations, and lack of control. A box making machine puts packaging production back in the hands of the manufacturer. This independence ensures consistency, lowers supply chain risks, and gives factories the ability to adapt instantly to new orders or changes in product dimensions.

6. Improved Customer Experience

Packaging is often the first physical interaction a customer has with a brand. Oversized or poorly packed cartons can give the impression of carelessness. By contrast, a carton produced by a box making machine is snug, professional, and protective. Products arrive in better condition, and customers notice the attention to detail—leading to higher satisfaction and repeat business.

Real-World Impact

Many factories that have adopted a box making machine report dramatic improvements. Packaging time is cut nearly in half, logistics costs drop significantly, and customer satisfaction rises as products arrive in neat, perfectly fitted cartons.

As one operations manager explained:

“We used to see packaging as an unavoidable expense. Now, with our box making machine, it’s a source of savings and competitive advantage.”

Conclusion

The rise of the box making machine marks a turning point in packaging. Traditional carton procurement is slow, costly, and inflexible—no longer fit for the demands of modern production. By adopting a box making machine, factories gain speed, efficiency, and sustainability, while also cutting costs.

In a market where every second and every dollar counts, the box making machine is not just a convenience—it is the future of packaging.