Things to Consider When Buying a Used Multi-Blade Saw

In the wood processing industry, multi-blade saws are common equipment. For some factories, purchasing used machinery may seem like an attractive option to save on initial costs. However, a cheap used multi-blade saw may hide high hidden costs and production risks.

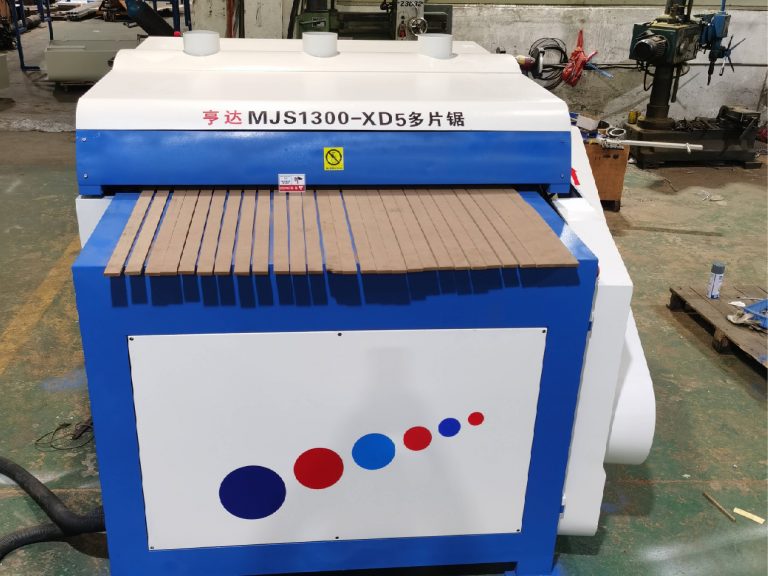

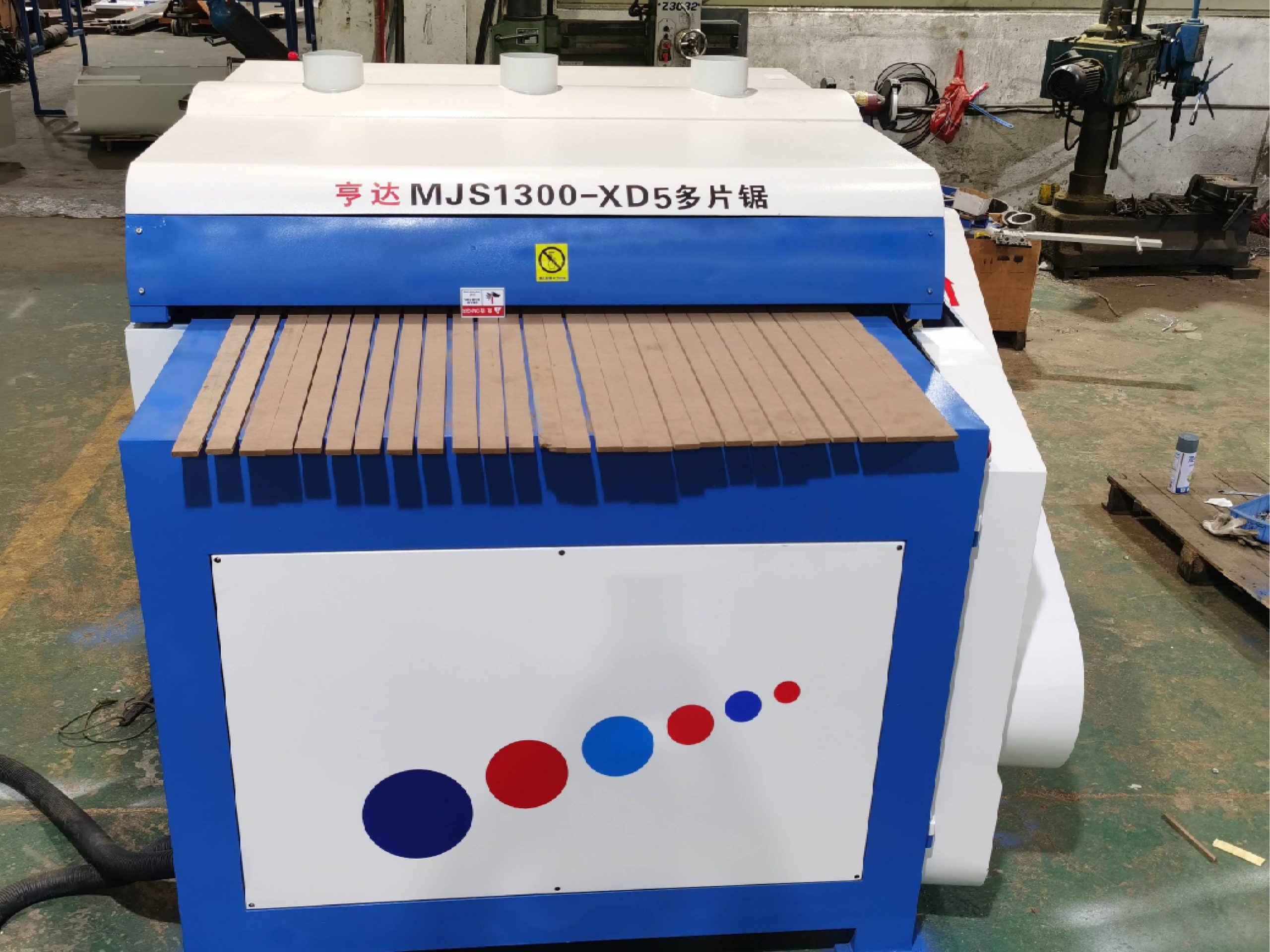

While we understand that new equipment (such as Hengda multi-blade saws) offers unparalleled performance guarantees, technical support, and longer service life, we also recognize that budget constraints may lead some factories to consider used machines. This article provides a detailed checklist to help you minimize risks and make a wiser decision when evaluating a used multi-blade saw.

Why Are Used Multi-Blade Saws “Tempting”? And What Are the “Hidden Traps”?

The most obvious advantage of buying used equipment is the lower initial investment. However, a used machine with an unknown history and condition may come with:

- Uncertain usage history and wear, leading to unexpected breakdowns.

- Lack of manufacturer warranty and technical support, making repairs difficult and costly.

- Outdated or worn components, reducing cutting accuracy and failing to meet modern production demands.

- Potential safety hazards, endangering operators.

- Lower efficiency and material waste, ultimately increasing overall operating costs.

Before making a decision, carefully inspect the following four key aspects:

Key Inspection Points: Four Critical Considerations When Buying a Used Multi-Blade Saw

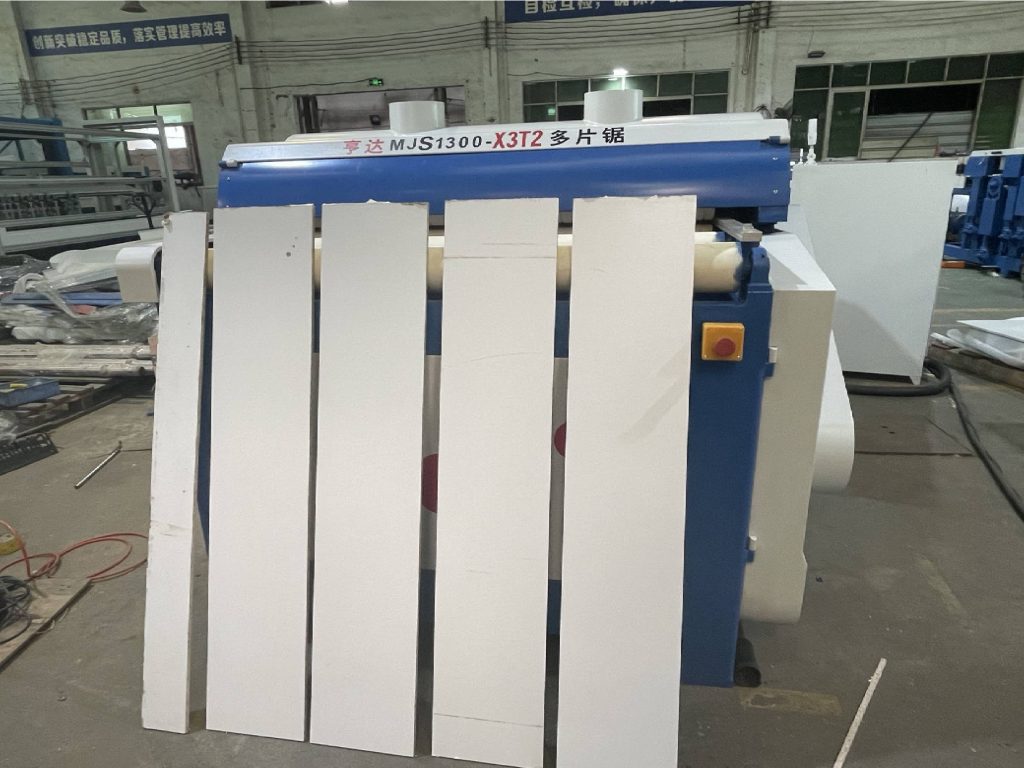

1. Cutting Performance

The core function of a multi-blade saw is precise cutting, and its condition directly affects product quality. The cutting accuracy of used machines is often unreliable, leading to material waste and inconsistent product quality.

- Spindle Inspection: The spindle holds the saw blades and is crucial for cutting precision. When running the machine, check for visible wobbling, vibration, or unusual noises. Gently shake it to feel for looseness. Any spindle issues will result in uneven cuts, inconsistent dimensions, or even burn marks.

- Bearing Condition: Listen for sharp grinding, humming, or resistance during operation. Worn bearings are common and can affect spindle stability and speed.

- Motor Power & Operation: Ensure the spindle motor starts and accelerates smoothly. Watch for overheating or unusual smells.

- Cutting Accuracy Test: If possible, conduct an on-site test cut. Check if the cut surface is smooth, even, and free of burrs or burn marks. Measure multiple pieces to confirm dimensional consistency.

- Blade Locking Nut: Verify that the saw blades are securely locked in place without any looseness. A loose blade can fly off, posing extreme danger.

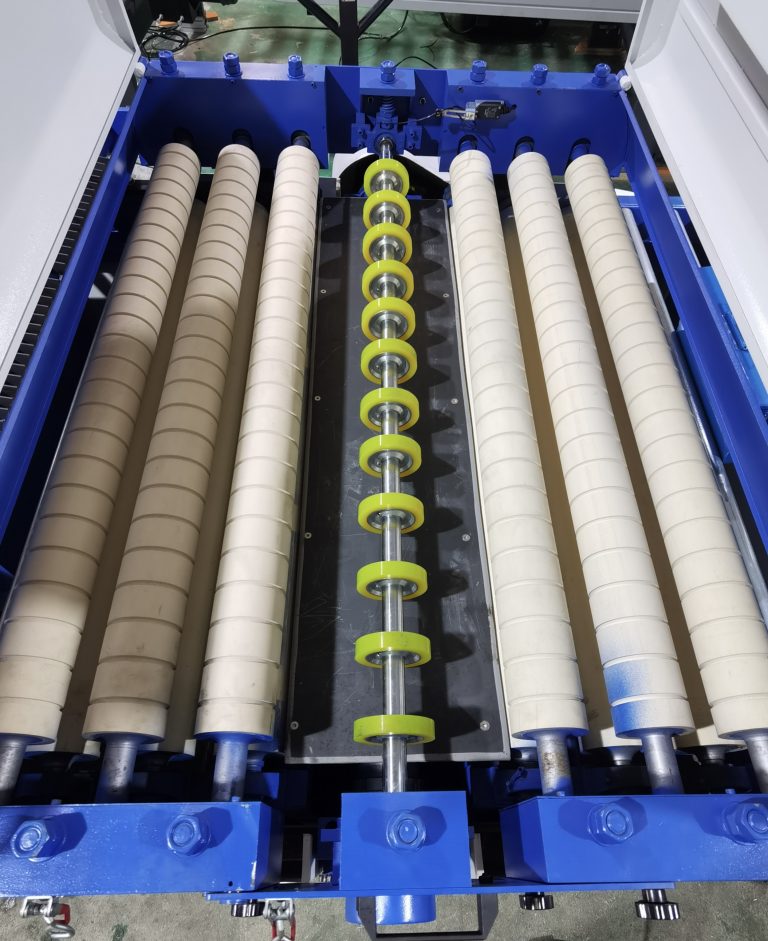

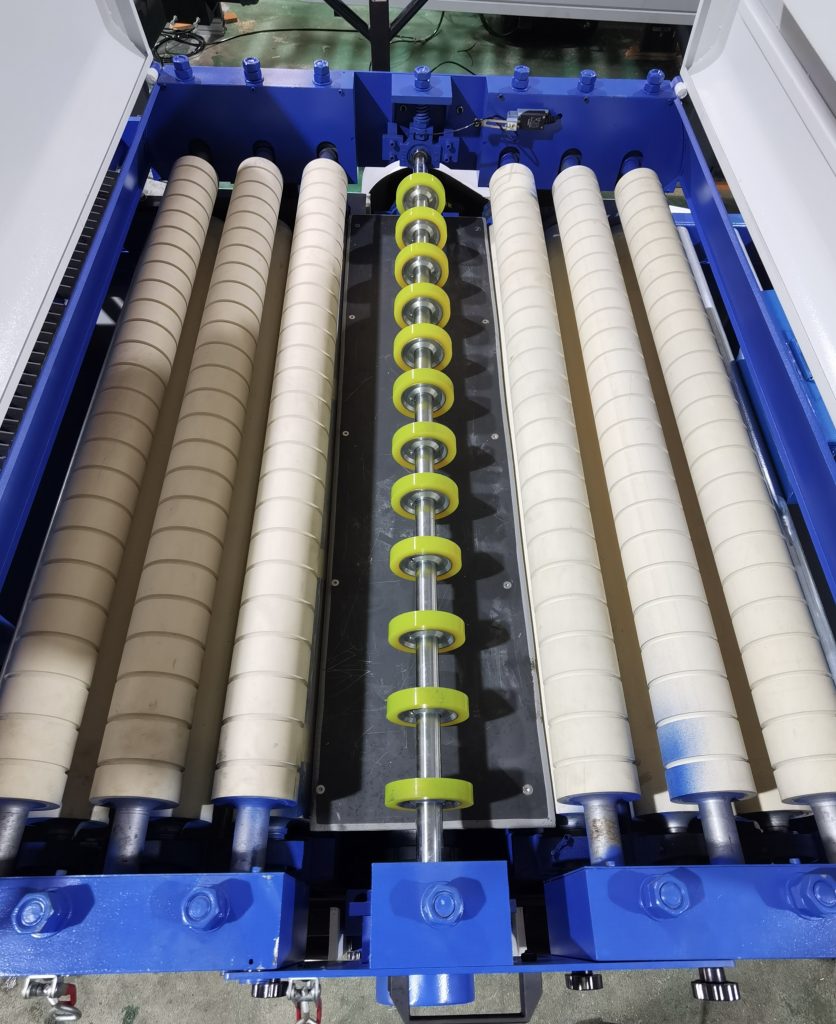

2. Conveyor System

The conveyor system ensures stable and smooth feeding of the wood through the saw blades.

- Rubber Roller/Track Wear:

- Roller Type: Check for aging, cracking, hardening, or deformation. Worn rollers can cause slippage, leading to uneven cuts or jamming.

- Track Type: Inspect for breaks, slack, or uneven wear. Examine the chains and gears for rust or excessive wear.

- Conveyor Motor & Speed: Test if the motor runs smoothly and if the feed speed adjusts properly without jerking or stalling.

- Clamping Force: Ensure the upper and lower pressure rollers firmly hold the wood. Insufficient clamping can cause kickback, which is extremely dangerous.

- Tracking Issues: Observe whether the wood moves straight without veering sideways under no-load or light-load conditions.

[Hengda Tip: Traditional track-type conveyors often suffer from slippage and uneven pressure, increasing kickback risks and cutting errors. Hengda multi-blade saws feature a unique synchronized rubber roller system, ensuring no slippage and stable feeding. The powerful clamping force of the upper and lower rollers securely holds the wood, preventing kickback—especially crucial for large, thick boards—while improving safety and cutting consistency.]

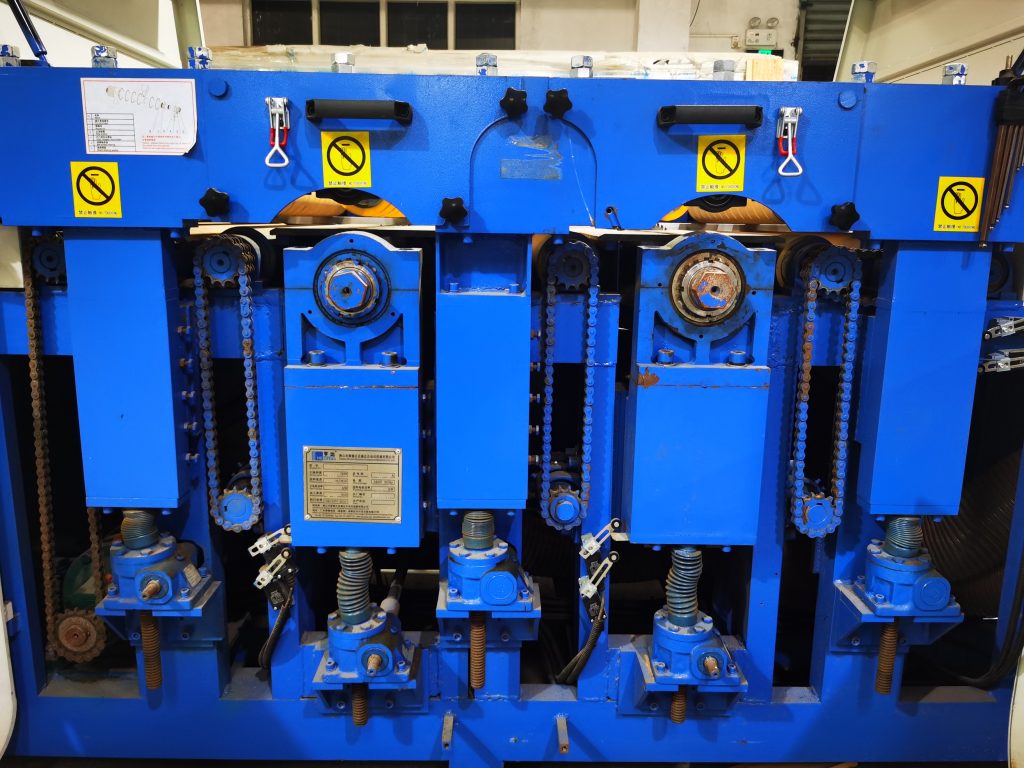

3. Height Adjustment Mechanism

The blade height adjustment system allows the saw to handle different wood thicknesses and cutting requirements.

- Manual Lifting Mechanism:

- Handwheel Operation: Check if it turns smoothly without sticking or excessive play.

- Screw & Guide Rails: Inspect for wear, rust, or deformation. These components support and guide the blade assembly—any damage will affect stability.

- Smooth Movement: Test if the blade assembly moves up and down steadily without shaking or tilting.

- Reliable Positioning: After adjusting the height, verify that the locking mechanism holds the blades firmly to prevent shifting during operation.

4. Safety Features

The biggest risk with used equipment is potential safety hazards. Safety should always be the top priority—a machine with hidden dangers can outweigh any cost savings.

- Safety Guards & Doors: Ensure all protective covers are intact, undamaged, and effectively shield hazardous areas. Safety covers (e.g., those that stop the machine when opened) must function correctly.

- Emergency Stop Buttons: Confirm they are easily accessible and immediately halt all machine motion when pressed.

- Electrical Wiring: Visually inspect for frayed, exposed, or disorganized wiring. Verify proper grounding.

- Anti-Kickback Devices: Check if anti-kickback claws, dividers, or other safety mechanisms are intact, sharp, and correctly installed to prevent wood from being thrown back.

Final Consideration: Balancing Used vs. New

While a used multi-blade saw may seem cost-effective initially, it often comes with unpredictable repair expenses, lower efficiency, inconsistent product quality, and serious safety risks. A heavily worn, outdated, or unsupported machine may become a long-term burden.

In contrast, a new machine offers:

- Guaranteed Performance: Factory-fresh precision and efficiency.

- Reliable Operation: Minimized downtime and consistent production.

- Full Support: Professional technical assistance, maintenance, and genuine spare parts.

- Enhanced Safety: Compliance with the latest safety standards.

- Longer Lifespan & Higher Resale Value.

Before deciding, weigh the true long-term costs—sometimes, investing in new equipment is the smarter choice.