The Ultimate Guide of Multi-Blade Saw Blades

Multi-blade saw blades, as the name suggests, are saw blades designed for simultaneous installation and use. Typically made of alloy, these blades play a vital role in wood processing, efficiently handling various materials such as fir, poplar, pine, eucalyptus, imported timber, and mixed wood. They are widely used in wood plank processing, joist production, furniture manufacturing, and more.

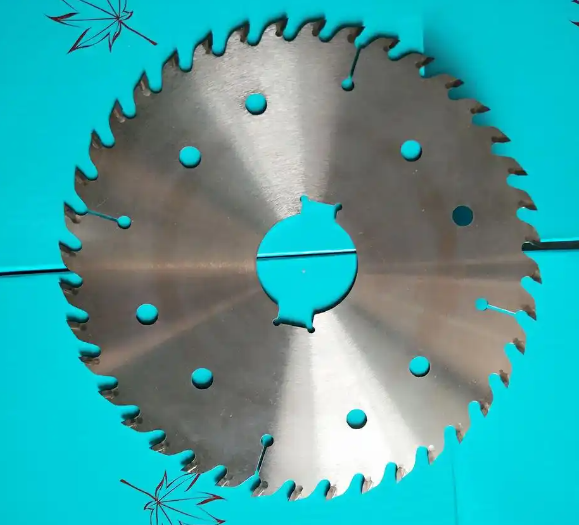

Basic multi-blade saws accommodate 10~20 blades, while large-scale models can hold over 40 blades, significantly boosting productivity. To enhance performance, these blades often feature heat dissipation holes, expansion slots, or multiple scrapers, ensuring smooth chip removal and optimal cooling.

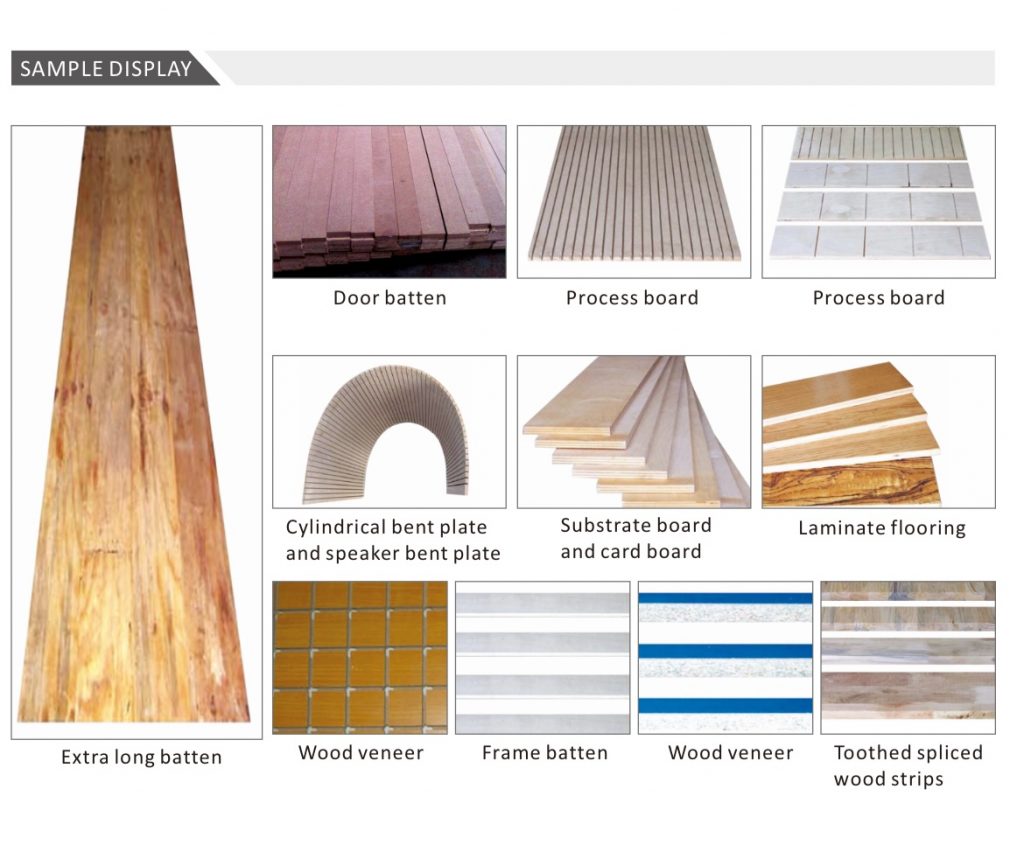

Diverse Applications of Multi-Blade Saw Blades

- Solid Wood Cutting: Efficiently processes solid wood for diverse craftsmanship needs.

- Plywood Core Cutting: Delivers precise cuts for accurate core board dimensions.

- Engineered Flooring Core Cutting: Accelerates production with high-speed processing.

- Engineered Flooring Surface Splitting: Specially designed for effortless surface splitting with superior results.

Key Features of Multi-Blade Saw Blades

- Ideal for longitudinal solid wood cutting; grouped use dramatically improves efficiency.

- Combines exceptional cutting quality with outstanding durability.

Blade Diameter Specifications

| Model | HD1300-X3L | HD1300-XD3L | HD1300-XD4L |

|---|---|---|---|

| Specification | 205*74*2.2*60T | 255*85*3.0*48T | 270*90*3.0*48T |

| Diameter(D/mm) | 205(≈8 inches) | 255(≈10 inches) | 270(≈10.6 inches) |

| Bore Diameter(d/mm) | 74 | 85 | 90 |

| Thickness(b/mm) | 2.2 | 3.0 | 3.0 |

| Number of Teeth(T) | 60T | 48T | 48T |

- Blades are designed with moderate diameters to balance strength and cutting efficiency.

- Optimal sizing minimizes vibration and wear during high-speed operation, extending service life.

- Designed to fix with the machine device and processing.

Selection Criteria:

Machine installation limits and material thickness dictate blade diameter, which ranges from 200 mm to 450+ mm. Some setups require top/bottom blade configurations (like HD1300-XT2) to achieve double sides cutting or slotting and without enlarging diameter, thereby reducing production costs.

Tooth Count Optimization

To reduce operational resistance, enhance durability, and minimize noise, multi-blade saws typically feature fewer teeth:

For example:

- 200–260 mm blades: 45–60 teeth

- 260+ mm blades: 45–70 teeth

- High-power machines or precision-focused manufacturers may use select blades with ~50 teeth.(HD1300-XD4L)

Blade Thickness Considerations

Theoretically, the thinner the saw blade, the better, as saw kerf is an unavoidable consumption. However, the thickness of the saw blade is not the thinner the better, because a saw blade with too thin a thickness is prone to wobbling when working, which affects the straightness of the plate opening and thus the cutting effect. The alloy saw blade’s base material and manufacturing process together determine the thickness of the saw blade.

Arbor Hole Sizing

The primary consideration when choosing the hole diameter of a multi-blade saw blade is the requirements of the machine. Since a multi-blade saw requires multiple blades to be mounted at the same time, the aperture design is usually larger than that of a conventional saw to ensure stability. In most cases, an enlarged aperture design with special flanges and keyways is used, which not only facilitates the addition of coolant for cooling, but also further enhances stability.

Common designs include:

- 200–260 mm blades: 70–85 mm diameter (often with flanges/keyways for coolant delivery)

- 260–290 mm blades: 90–100 mm diameter

- 300+ mm blades: ≤100 mm diameter

Tooth Geometry

The teeth of a multi-blade saw are usually designed in an alternating left-right pattern, which is designed to ensure that they provide a stable cut during the sawing process. However, for certain small diameters, saw blades may also be designed with flat teeth in order to suit specific application scenarios. This design choice is intended to meet the needs of different sawing tasks.

Coating Process

During the manufacturing process of multi-blade saw blades, a coating is applied after the welding and resharpening is completed. This step not only helps to extend the service life of the saw blade, but more importantly, it improves the aesthetic appearance of the blade. Particularly in the case of saw blades with scrapers, where the current level of welding leaves visible weld marks on the scrapers, the coating process is particularly important to ensure the aesthetics of the product.

Scraper-Equipped Blades

During the manufacturing process of multi-blade saw blades, cemented carbide is added to the saw blade substrate, which are collectively known as scrapers. Scraper design can be divided into internal scraper, external scraper and tooth scraper according to its purpose.

- Internal scrapers: For hardwoods

- External scrapers: For wet wood

- Tooth scrapers: For edge trimming/sealing

However, it should be noted that these categorizations are not absolute, and specific applications need to be tailored to the actual situation.

Design Trends:

- <10″ blades: 2–4 scrapers (mostly external)

- ≥12″ blades: Balanced internal/external scraper symmetry

Advantages:

- Higher efficiency in wet/hardwood cutting

- Reduced gumming, burning, and sharpening frequency

- Improved chip evacuation and longevity

Challenges:

- Complex sharpening requirements

- Higher cost compared to standard blades