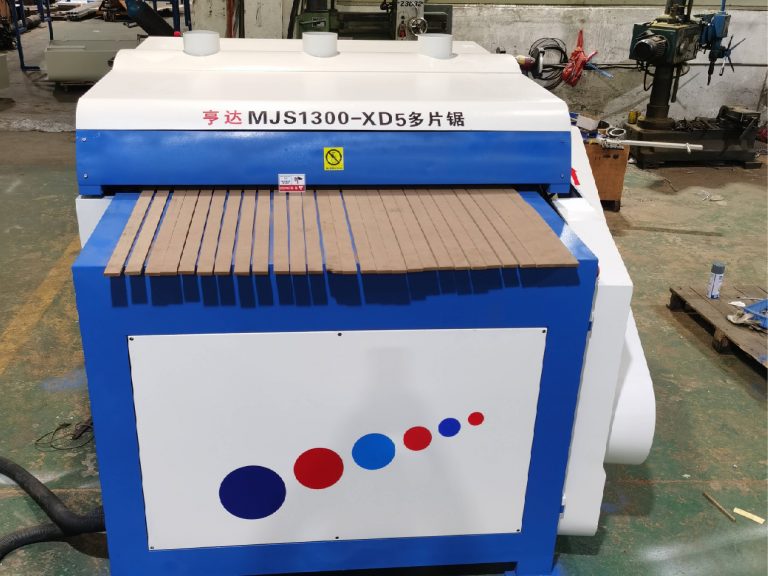

The Saw Blades For Wood Plank Multi Blade Rip Saw Machine

A multi-rip saw blade is a common woodworking tool that can cut multiple pieces of wood plate simultaneously, significantly improving work efficiency. It’s widely used in the woodworking industry and has become an essential tool for many carpenters.

A multi-rip saw blade is an essential tool for improving work efficiency, offering advantages such as high cutting precision, smooth cutting surfaces, and a wide range of applications. When using one, remember to choose the right blade, adjust its height, secure the wood, and prioritize safety.

Advantages of Multi-Rip Saw Blades

Compared to traditional single-saw blades, multi-rip saw blades offer the following advantages:

- Increased Work Efficiency: Multi-rip saws can cut multiple pieces of wood at once, greatly boosting productivity.

- High Cutting Precision: These saw blades provide high cutting accuracy, ensuring that the cut wood dimensions are precise.

- Smooth Cutting Surface: Wood cut with a multi-rip saw blade has a smooth surface, free of burrs or damage.

- Wide Application Range: Multi-rip saw blades can cut various types of wood materials, making them highly versatile.

How to Use Multi-Rip Saw Blades

When using a multi-rip saw blade, keep the following in mind:

- Choose the Right Saw Blade: Different types of processing require different saw blades. Selecting the appropriate blade improves working efficiency and precision.

- Adjust Saw Blade Height: Adjust the saw blade’s height according to the thickness of the wood you need to cut to ensure the correct cutting depth.

- Secure the Wood: Before cutting, secure the wood to prevent it from moving during the cutting process.

- Pay Attention to Safety: Always prioritize safety when using a multi-rip saw blade to avoid accidents and injuries.

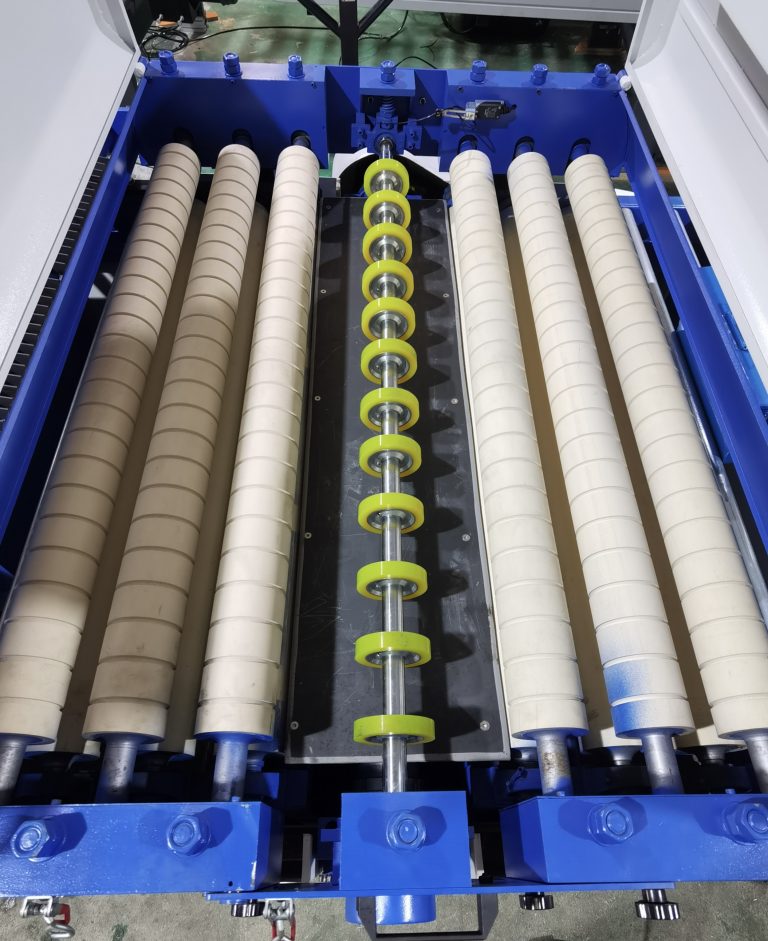

Analysis of Saw Blade Core Structure

- Saw Blade Substrate: Primarily made of high-carbon steel or alloy steel. Some high-end products use nickel-chromium-molybdenum alloy, combining toughness and rigidity.

- Carbide Tool Head: Mostly uses tungsten-cobalt (YG) cemented carbide. For extreme working conditions, tungsten-titanium-cobalt (YT) alloy can be chosen to enhance high-temperature resistance.

- Heat Dissipation Hole Design: Radially distributed silencing holes not only reduce temperature and noise but also optimize chip removal paths through airflow.

Key Features of The Saw Blades

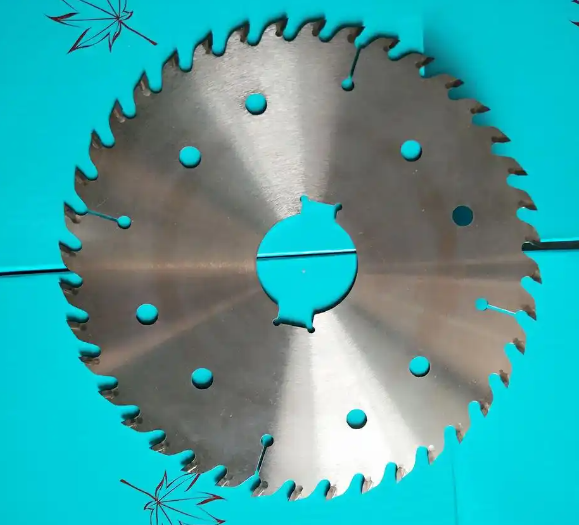

Outer Diameter Differences

Key Impacts:

- Maximum Cutting Thickness

- Larger diameter blades enable greater maximum cutting depth. This is the most direct effect.

- Peripheral Speed

- At the same RPM, larger blades have higher edge speed.

- Pros: Smoother cuts (each tooth travels farther per rotation).

- Cons: Increased friction/heat, demanding better blade materials and cooling.

- Stability & Vibration

- Improper diameter selection (too large/small) can cause instability.

- Optimal diameter minimizes vibration for specific material thicknesses.

- Power Consumption

- Larger blades require higher motor power to maintain speed/torque.

Bore Diameter Differences

Key Impacts:

- Spindle Compatibility

- Bore diameter must precisely match the saw’s arbor size for secure, wobble-free mounting (critical for safety/accuracy).

- Stability & Rigidity

- Larger bores typically fit sturdier spindles, reducing vibration/deflection during heavy/high-speed cuts.

- Torque Transmission

- Larger arbors transfer motor torque more efficiently—essential for dense/hard materials.

Thickness Differences

Key Impacts:

- Material Waste

- Thinner blades reduce wood loss, improving yield—crucial for expensive lumber.

- Stability vs. Rigidity Trade-off

- Thinner Blades: More prone to deflection, requiring precise equipment. Best for fine cuts on stable materials.

- Thicker Blades: Resist bending, ideal for hardwoods or thick stock.

- Heat Dissipation

- Thicker blades dissipate heat better, preventing burning during prolonged use.

- Feed Rate

- Thicker blades often allow faster feeding due to stronger chip removal.

Number of Teeth Differences

Key Impacts:

- Cut Quality/Finish

- More teeth = finer cuts (lower “chip load” per tooth), producing smoother surfaces with less tear-out.

- Feed Rate Adjustment

- High Tooth Count: Slower feed rates needed to avoid overheating.

- Low Tooth Count: Permits faster feeding, suited for rough milling/high-volume work.

- Chip Evacuation

- Excessive teeth may clog due to limited gullet space, leading to overheating.

- Noise Levels

- Higher tooth counts generally increase operational noise.

Saw Blade of Hengda Gang Rip Saw Machine

| Model | HD1300-X3L | HD1300-XD3L | HD1300-XD4L |

|---|---|---|---|

| Specification | 205*74*2.2*60T | 255*85*3.0*48T | 270*90*3.0*48T |

| Diameter(D/mm) | 205(≈8 inches) | 255(≈10 inches) | 270(≈10.6 inches) |

| Bore Diameter(d/mm) | 74 | 85 | 90 |

| Thickness(b/mm) | 2.2 | 3.0 | 3.0 |

| Number of Teeth(T) | 60T | 48T | 48T |

Conclusion

The blade setup suggests the HD1300-X3L is optimized for high-precision ripping of thinner materials where material yield and cut quality are critical. It would be good for finished components where minimal sanding is desired.

And HD1300-XD3L is designed for general-purpose ripping of a broader range of material thicknesses, balancing cut quality with productivity. It would be a common choice for many furniture and door frame components.

HD1300-XD4L is the heavy-duty option, ideal for high-volume ripping of thick and/or harder materials where throughput is a primary concern. It’s built for demanding industrial environments.