The Critical Role of Nitrile Rubber Rollers Conveyor in Wood Panel Multi-Blade Saw Machine

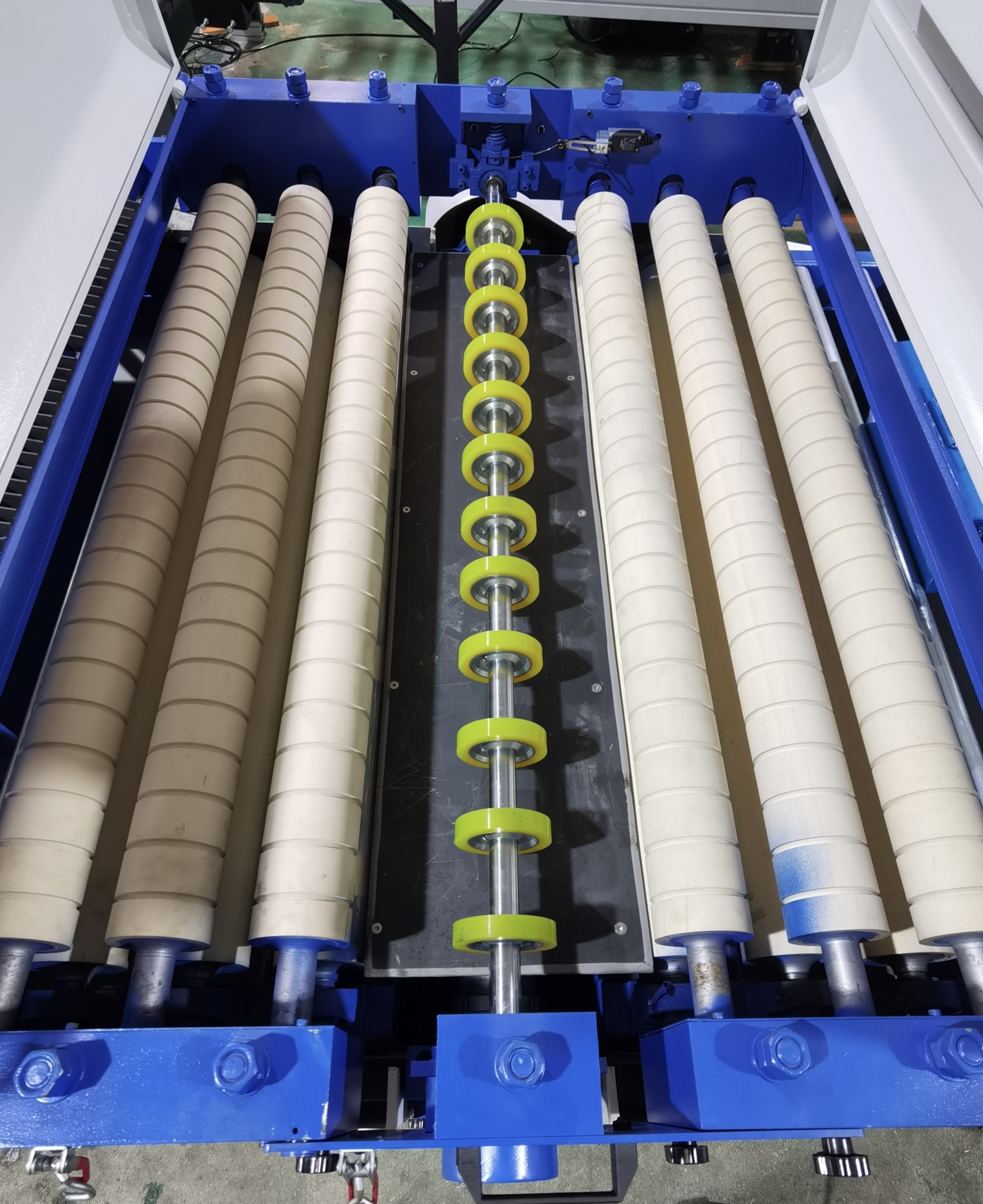

Conveyor rollers may seem like an inconspicuous component of a multi-blade saw machine, but they play a vital role. These rollers come into direct contact with the wood, ensuring smooth and precise feeding into the cutting blades. What you may not realize is that the material quality of these rollers can significantly impact your production costs and product quality.

At Hengda, we understand the importance of every detail. That’s why we insist on equipping all our multi-blade saws with high-quality Nitrile Rubber (NBR) conveyor rollers, rather than the inferior alternatives commonly found on the market. Today, we’ll explore why this seemingly minor choice actually affects your investment and returns.

Why Conveyor Rollers Matter

Imagine: hard wood, high-speed cutting, and constant friction day after day. In such demanding conditions, conveyor rollers must provide consistent grip to prevent slippage, misalignment, or kickback. They are essential for precise cutting and operational safety. If the rollers perform poorly, even the most powerful motor and sharpest blades won’t deliver optimal results.

The Hidden Costs of Low-Quality Rollers

To cut costs, some manufacturers use cheap rubber blends for their rollers. Initially, these may seem fine, but over time, their flaws become apparent:

- Poor Grip: Standard rubber rollers have low friction coefficients, especially when handling wood with sawdust, resin, or moisture. This leads to slippage, uneven cuts, and dangerous kickback.

- Low Durability: Cheap rollers wear out quickly, becoming cracked, hardened, and less elastic, drastically shortening their lifespan.

- Rapid Performance Decline: After some use, inferior rollers degrade, requiring frequent repairs and replacements.

Why Hengda’s Nitrile Rubber Rollers Excel

At Hengda, we never compromise on core components. Our multi-blade saws use premium Nitrile Rubber (NBR) rollers, known for their superior industrial performance:

- Exceptional Grip – NBR provides high friction and elasticity, ensuring stable feeding even on rough, uneven, or slightly damp wood. No slippage, no kickback.

- Superior Durability – NBR resists wear, oil, heat, and aging, far outperforming standard rubber. This means longer service life and lower replacement costs.

- Consistent Cutting Precision – Smooth feeding ensures cleaner, more accurate cuts, reducing material waste.

- Enhanced Safety – Stable feeding + Hengda’s dual-roller clamping system eliminates kickback risks, protecting operators.

Cost Comparison: Quality vs. Cheap Alternatives

You might wonder: Do high-quality NBR rollers increase machine costs? Yes—but it’s a smart investment:

- A single NBR roller may cost ~¥150 more than a cheap one.

- A standard multi-blade saw uses 12–16 rollers, increasing machine cost by ¥2,000–2,400.

However, this extra investment brings you years of trouble-free operation, reducing downtime and repair costs and higher productivity from stable performance. Also with safer operations, preventing costly accidents and better product quality, boosting market competitiveness.

Final Advice: Don’t Be Fooled by Low Prices

The choice of roller material may seem minor, but it fundamentally impacts a multi-blade saw’s long-term performance, operating costs, and safety. At Hengda, we prioritize quality in every component because we know: True savings come from excellence. Choosing Hengda means investing in reliable, efficient, and safe production for years to come.