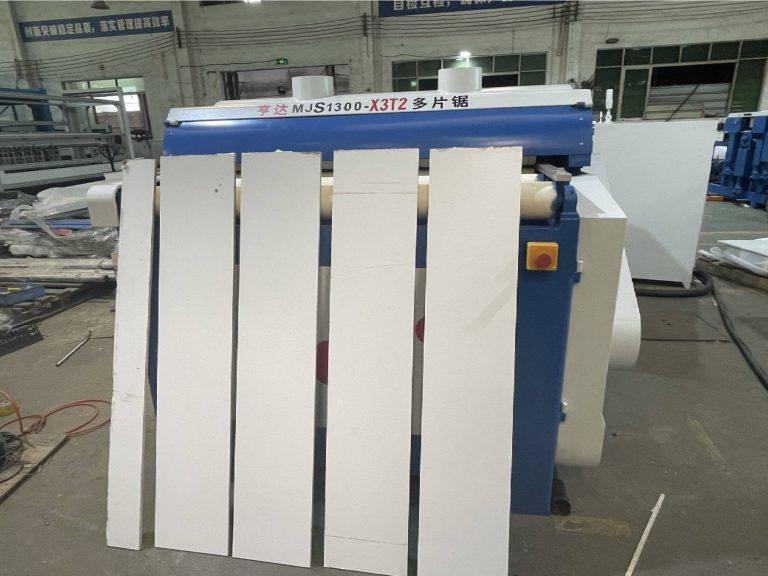

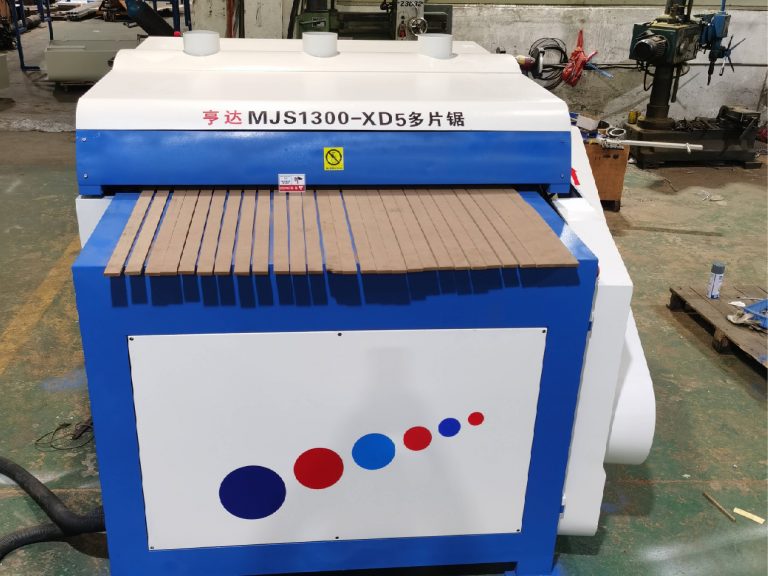

Tag wood panel multi blade rip saw machine

Depth Analysis of Wood Panel Multi-Blade Saw Machine 1300 Series

HENGDA 1300 Series of wood panel multi-blade saw machine offers both standard and custom-wide configurations to meet diverse processing needs. This article provides a detailed comparison of these models’ rubber-coated roller effective width and worktable dimensions, with special guidance for…

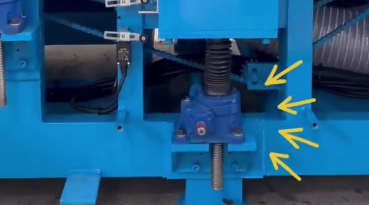

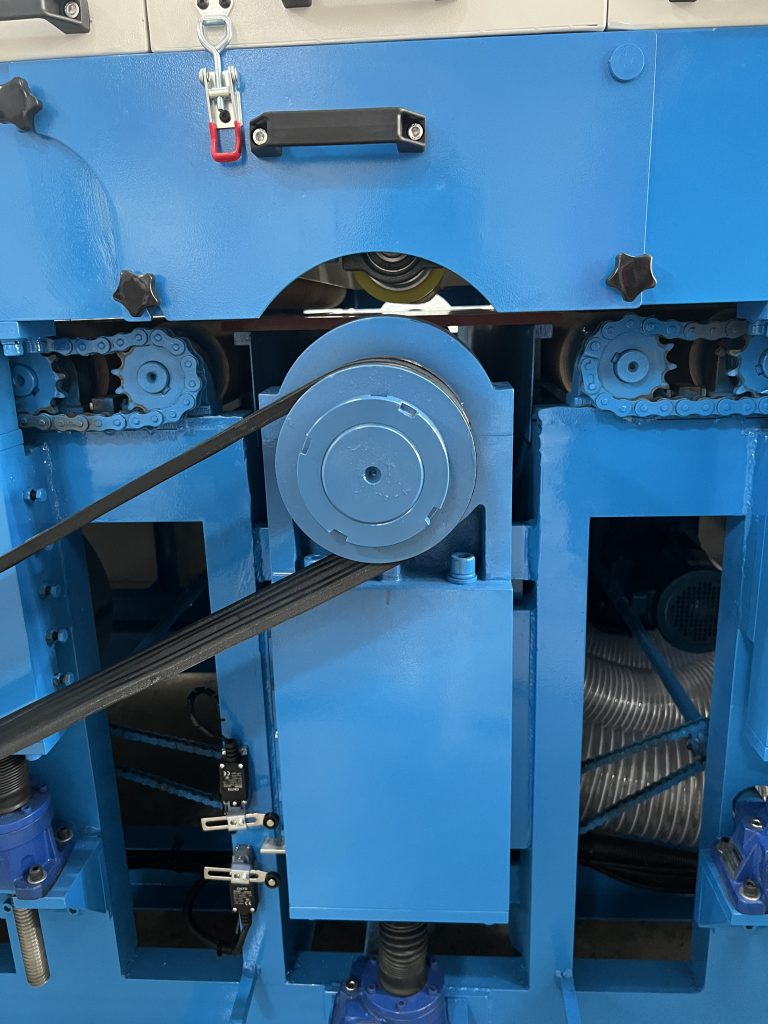

Wood Plate Multi-Blade Saw Machine: Electric Spindle Elevation

In woodworking industries, efficiency and precision define productivity. Traditional multi-blade saw machine rely on labor-intensive manual cranking for spindle height adjustment – a time-consuming process that compromises precision. HENGDA revolutionizes this experience with our innovative electric spindle elevation system, eliminating…

Hengda Multi-Blade Saw: Technological Synergy for Efficient, Quiet Cutting

In the woodworking industry, the pursuit of efficiency and user experience is never-ending. Previously, we shared how Hengda’s innovative spindle technology significantly reduces operational noise. But this is just one step in our journey toward excellence. Our technological upgrades represent…

Spacers For Hengda Wood Panel Multi-Blade Saw Machine

In the precision cutting process of wood panel multi-blade saws, many factors contribute to consistently high-quality cuts. One often overlooked yet crucial component is the saw blade spacer. These seemingly simple parts precisely determine the distance between saw blades on…

New Technology of Multi-Blade Saw Delivers Ultra-Low Noise Operation

In the bustling environment of woodworking workshops, high-decibel machine noise is often a major concern for operators and a disruptive factor in the workplace. Traditional multi-blade saws generate significant noise during high-speed operation, which not only affects employee health and…

Precision Casting of the Woodworking Multi Blade Saw Machine Frame

In the complex world of industrial machinery, the stability and long-term reliability of a piece of equipment often depend on its most fundamental yet easily overlooked “skeleton”—the machine frame. As a high-speed, high-intensity woodworking tool, the quality of a multi-blade…

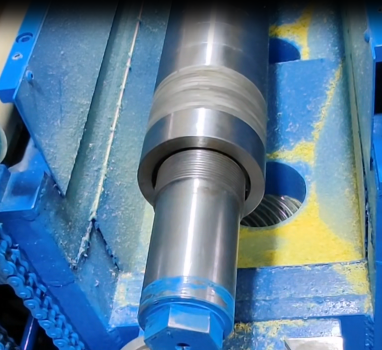

Engineering Advantages of Hengda Multi-Blade Saw Spindle

The spindle of a multi-blade saw is a critical core component that determines cutting precision and overall machine stability. Its quality and processing techniques directly impact the long-term performance of the equipment. Hengda equips all its multi-blade saws with spindles…

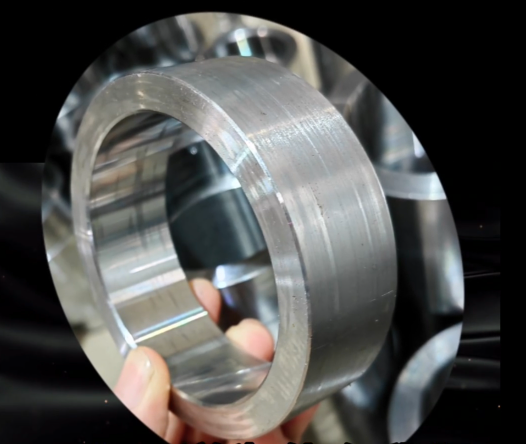

Ductile Iron For Multi-Blade Saw Spindle Bearing Housing

In many woodworking industrial factories, wood panel multi blade rip saw machine is very common. As a key piece of equipment in wood processing, the performance and lifespan of a multi-blade saw depend not only on motor power or blade…

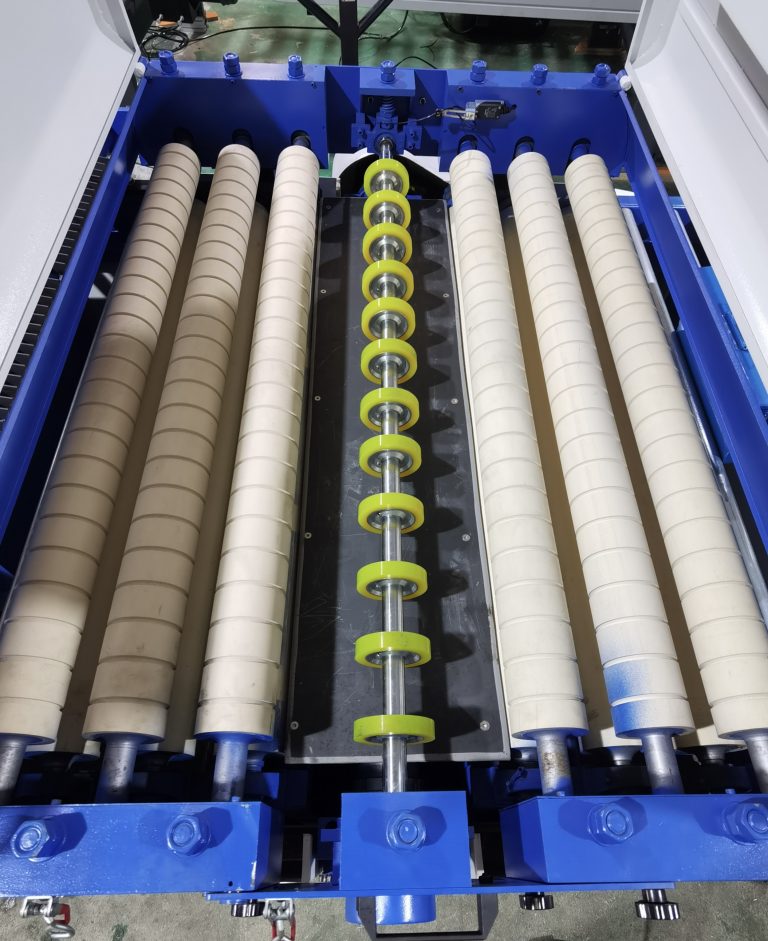

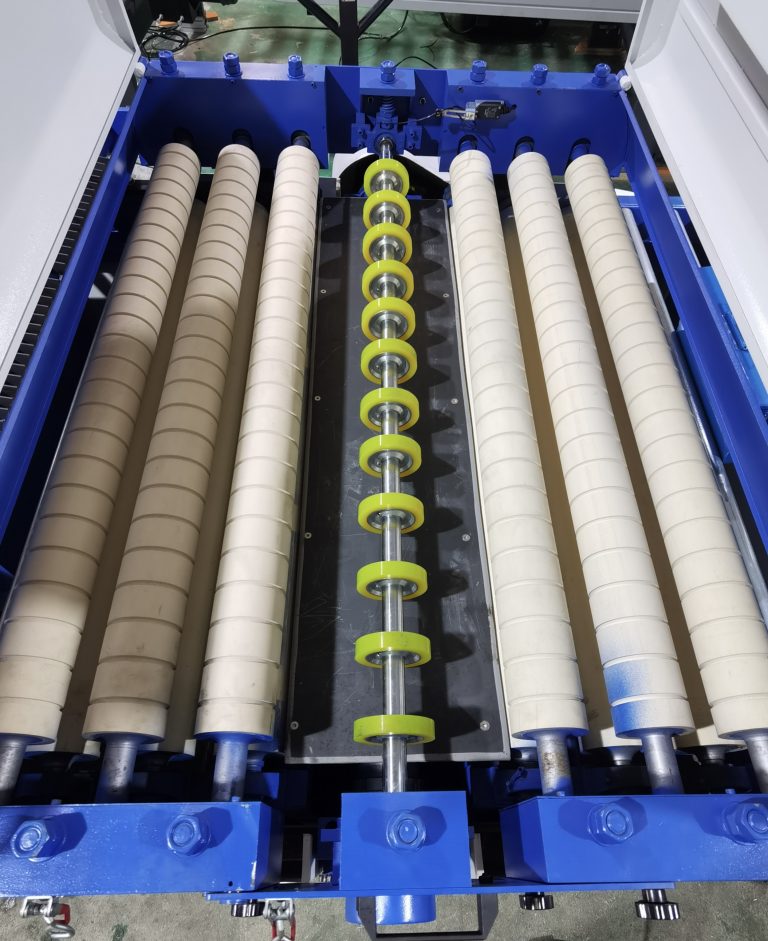

The Critical Role of Nitrile Rubber Rollers Conveyor in Wood Panel Multi-Blade Saw Machine

Conveyor rollers may seem like an inconspicuous component of a multi-blade saw machine, but they play a vital role. These rollers come into direct contact with the wood, ensuring smooth and precise feeding into the cutting blades. What you may…

Things to Consider When Buying a Used Multi-Blade Saw

In the wood processing industry, multi-blade saws are common equipment. For some factories, purchasing used machinery may seem like an attractive option to save on initial costs. However, a cheap used multi-blade saw may hide high hidden costs and production…