Spacers For Hengda Wood Panel Multi-Blade Saw Machine

In the precision cutting process of wood panel multi-blade saws, many factors contribute to consistently high-quality cuts. One often overlooked yet crucial component is the saw blade spacer. These seemingly simple parts precisely determine the distance between saw blades on the spindle, directly affecting cutting width and accuracy. At Hengda, we dedicate tremendous effort to crafting superior spacers, ensuring your multi-blade saw performs at its best.

Precision Manufacturing: The Core of Hengda Spacers

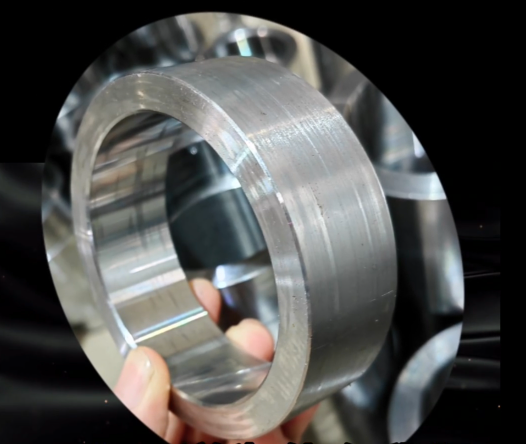

Custom Precision Cutting from Seamless Tubes

Every Hengda spacer starts as a section of seamless tube. Based on specific customer cutting requirements, each tube is precisely cut to custom lengths. This foundational step ensures the spacer’s initial dimensions are accurate before further processing.

CNC Turning for Ultimate Precision

After initial cutting, each spacer blank undergoes CNC turning. This advanced machining process allows us to control the spacer’s outer diameter, inner bore, and thickness with extreme precision. Our stringent quality standards demand these dimensions meet exacting tolerances.

Ultra-Precision Grinding for Critical Thickness

The most crucial dimension is the spacer’s thickness, as it directly determines the final cutting width. We subject each spacer to precision grinding, maintaining thickness tolerances within an ultra-tight ±0.02mm range. This superfine grinding process is key to achieving exceptional spacer performance.

Rigorous Quality Inspection for Perfect Fit

Upon completion, every spacer undergoes strict quality checks. This ensures each unit meets our exacting standards for dimensional accuracy and surface finish.

When installed on the spindle, this precision manufacturing guarantees perfect alignment between spacers, saw blades, and the spindle itself.

Advantages: Enhanced Performance & Extended Lifespan

Hengda’s high-precision, premium-quality spacers deliver tangible benefits for your multi-blade saw operations:

- Superior Cutting Accuracy: With spacer precision controlled within ±0.02mm, you achieve highly consistent and precise cutting widths, significantly reducing material waste and improving product quality.

- Enhanced Stability: The perfect fit between spacers, blades, and spindle minimizes potential wobble or vibration. This results in smoother cuts while reducing stress on both blades and spindle.

- Extended Blade Life: By ensuring stable blade positioning and reducing vibration, precision spacers help prolong saw blade lifespan, lowering consumable costs.

- Reduced Machine Wear: Stable cutting components decrease wear on the spindle and bearings, extending your saw’s overall service life.

- Reliable, Consistent Production: High-quality spacers guarantee dependable cutting processes, minimizing downtime while ensuring long-term output consistency.

At Hengda, we understand true quality lies in every detail. Our commitment to manufacturing exceptional saw blade spacers reflects our dedication to delivering multi-blade saws with unparalleled precision, stability, and long-term value.