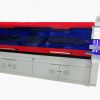

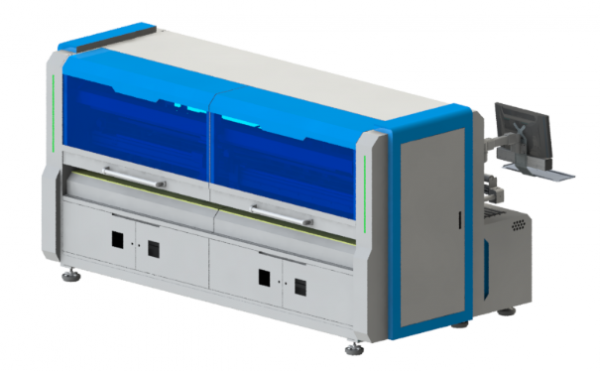

Flexible Corrugated Carton Box Making Machine for Multiple Short-Run Orders

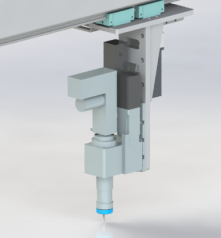

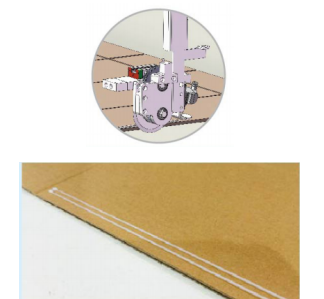

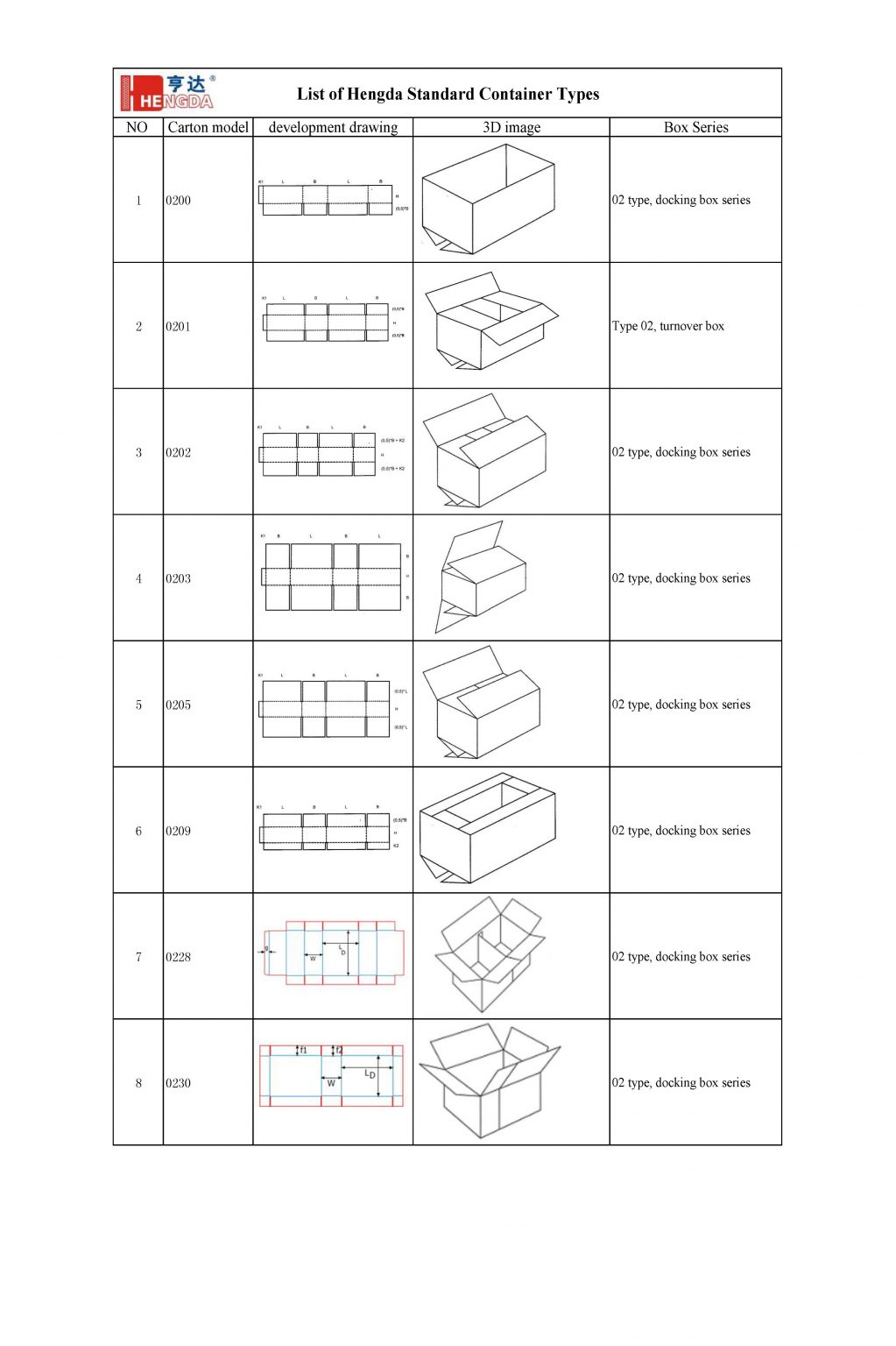

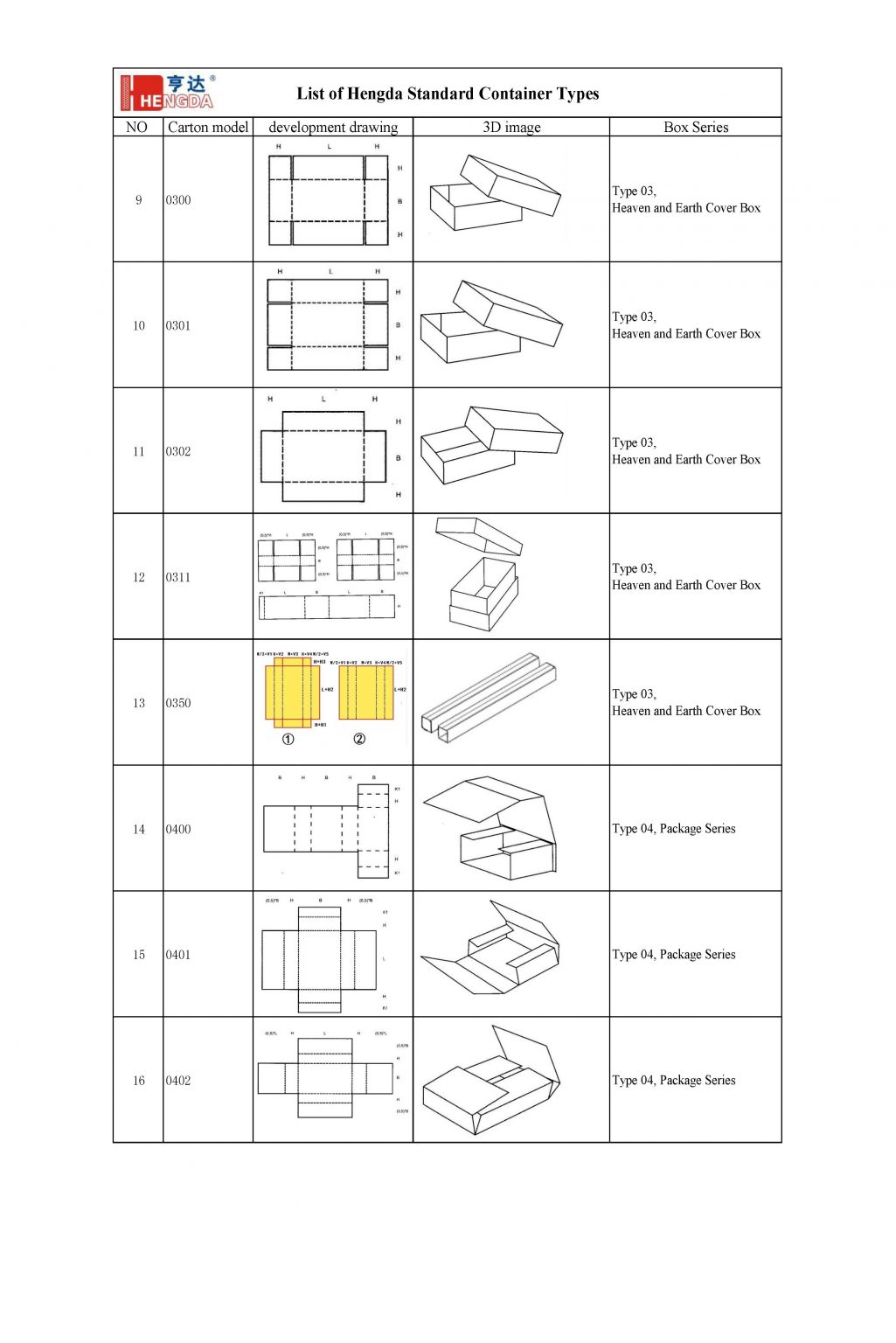

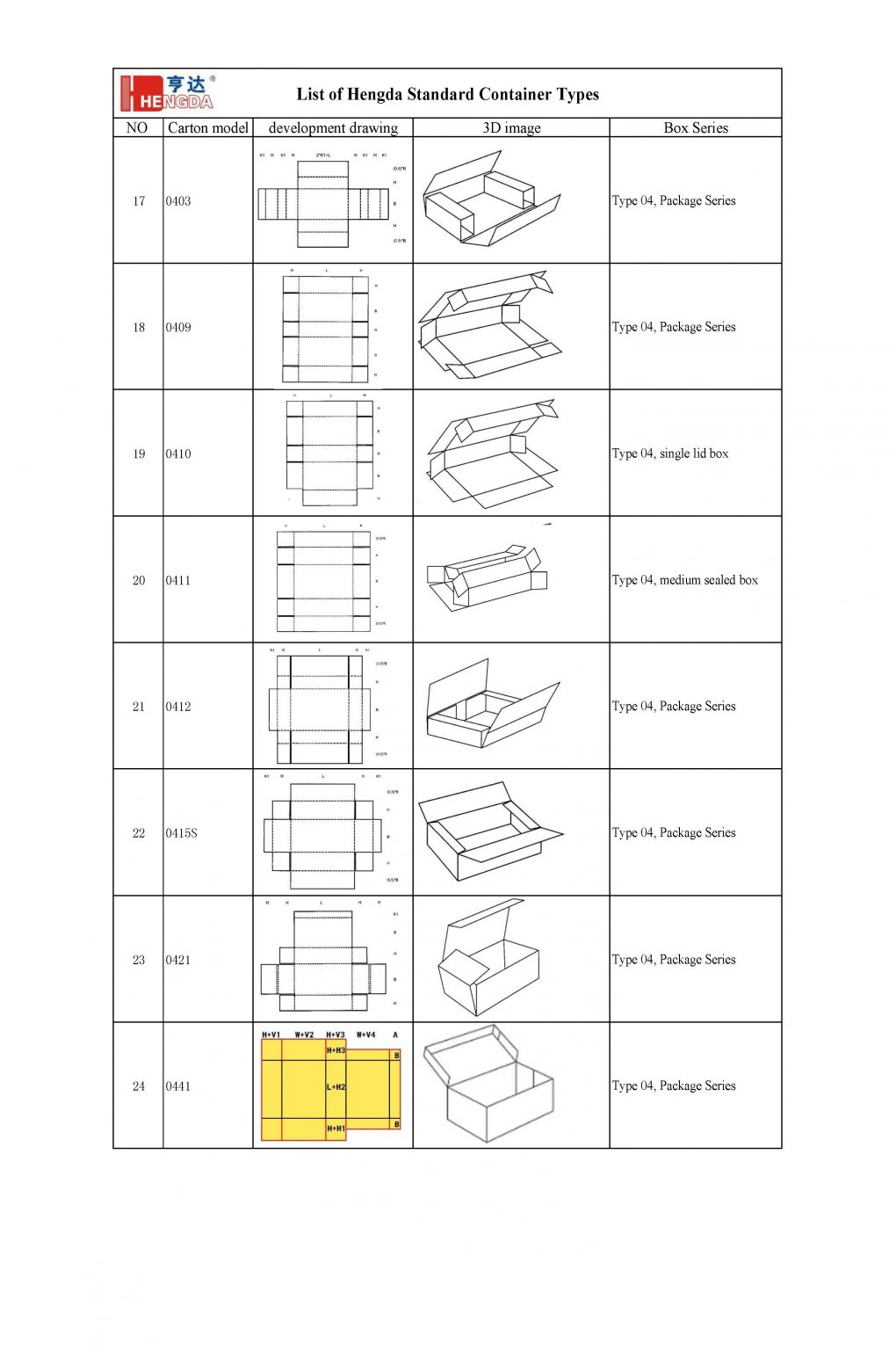

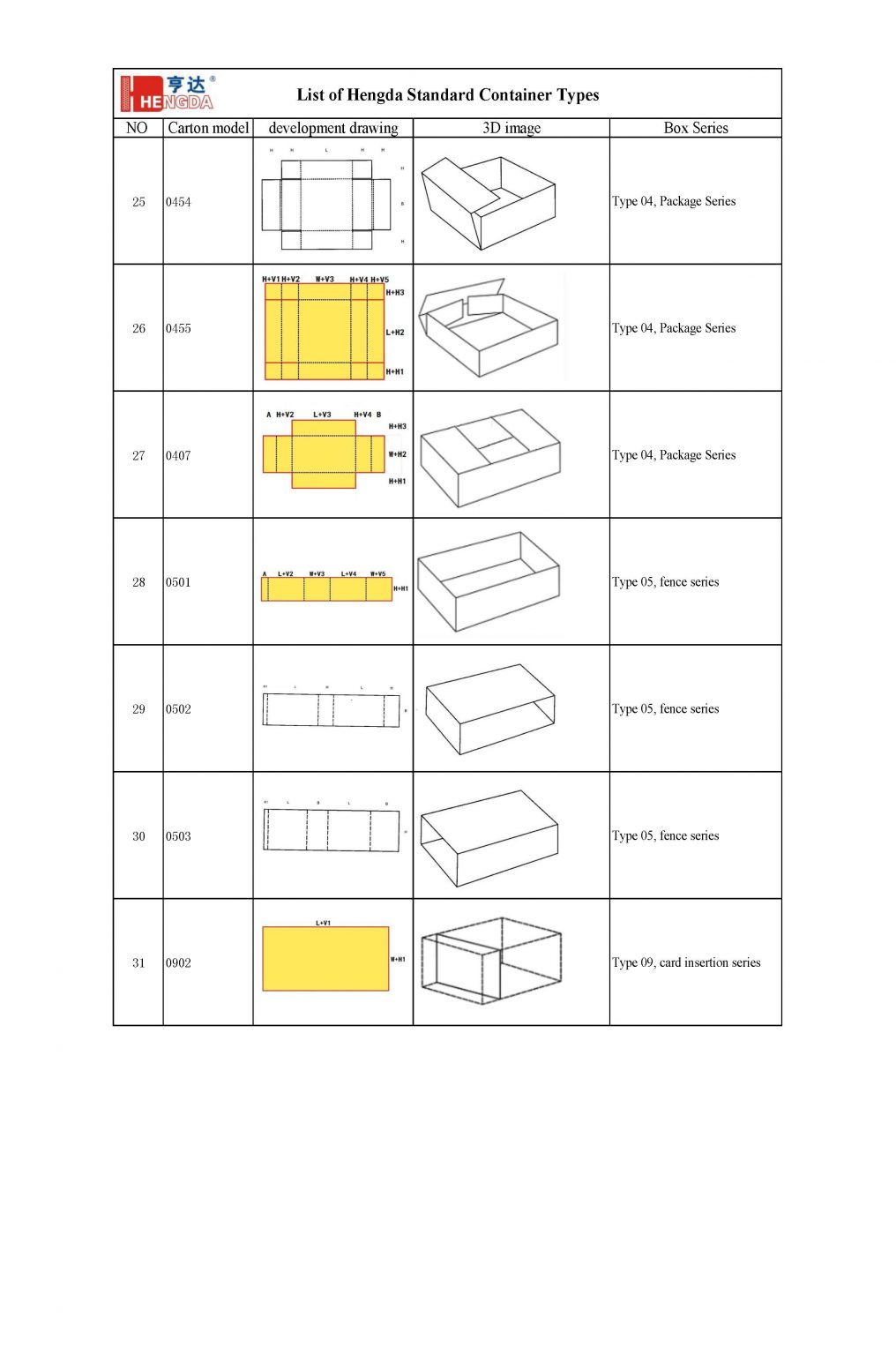

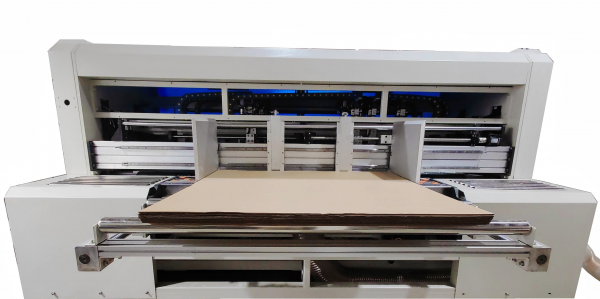

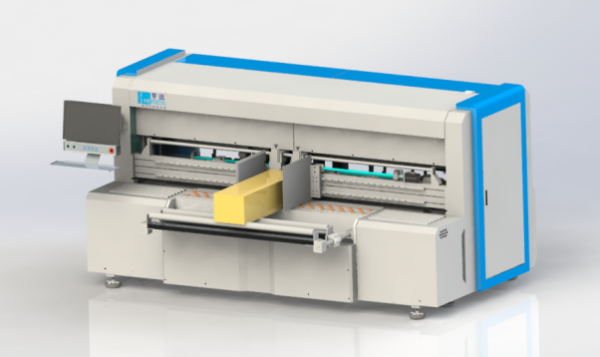

The HD2508-U flexible corrugated carton box making machine is designed for short-run and on-demand packaging. It combines slotting, creasing, cutting, and punching in one process without the need for dies. With quick job changeover and over 100 editable box styles, it enables fast production of multiple box sizes. Suitable for corrugated and honeycomb boards up to 25mm thick, the HD2508-U is ideal for packaging factories, furniture manufacturers, and e-commerce fulfillment centers that handle diverse, small-batch carton orders.