Plank Multi Blade Rip Saw Machine For Door Frame

In door and window manufacturing, precision isn’t optional—it’s everything. When a door frame is even 1mm off, the result can be misaligned fittings, rattling doors, or expensive rework. And in high-volume production, small inaccuracies quickly multiply into major losses—of materials, time, and profit.

So how do smart manufacturers avoid these hidden pitfalls? The answer lies in using the right equipment—machines that aren’t just powerful, but purpose-built for accuracy, speed, and consistency.

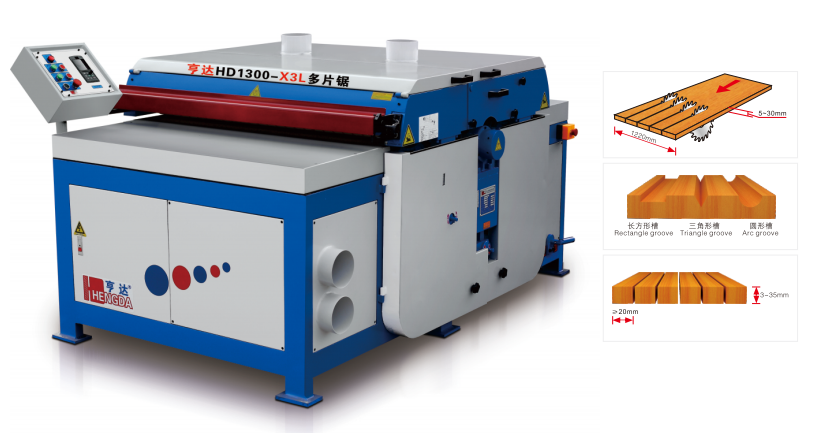

At Hengda, we design multi blade saw machine and automated production lines specifically for manufacturers like you—those who demand more than just a cut. You need a reliable, precise solution that fits your materials, your volumes, and your workforce.

Why Door Frame Precision Is Vital

A perfect door frame isn’t just about good-looking joints—it’s about operational excellence. Here’s what’s at stake when your cuts aren’t precise:

- Material Waste: Inaccurate cuts lead to off-spec components that get scrapped. That’s money thrown away in both raw materials and time.

- Slow Assembly: Parts that don’t fit properly stall your production line and increase labor costs.

- Product Issues: Misaligned frames mean doors that stick, rattle, or sag—hurting your brand’s reputation.

- Lost Time: Rework, re-cutting, and troubleshooting reduce your overall output.

How Hengda Plank Multi Blade Saws Solves the Problems

Our multi blade saw machines are engineered to eliminate these production headaches—starting with automated precision and ending with faster, smoother workflow.

1. Precision Cutting, Customized to Your Material

Whether you’re working with MDF, solid wood, or composite panels and any other wood materials, Hengda multi blade rip saws adapt to your materials—not the other way around. More than that, the machine can adapt to your raw material board sizes flexibly, ensuring optimal production regardless of your starting material. This adaptability means you can maximize material yield and achieve the exact dimensions required for every door frame component without compromise. For example, if you need to cut a board with 700mm width, we provide HD700 series instead of our standard HD1300 series.

Our saws deliver:

- Cutting width tolerance: ±0.2mm

- Straightness accuracy over 2.4m: ±0.5mm

That means door frame slats, linings, or pocket plates are consistently accurate—batch after batch—ensuring clean assemblies and fewer rejects.

2. Designed for High-Volume, Continuous Production

If you’re producing hundreds or thousands of frames daily, you can’t afford production jam.

Hengda Production Line Can Help You With:

- Continuous material cutting with high precision

- Automatic loading & unloading systems

- Continuous material feeding (0–17m/min adjustable)

This automation translates into:

- Faster production cycles

- Fewer operators needed

- Consistent performance across shifts

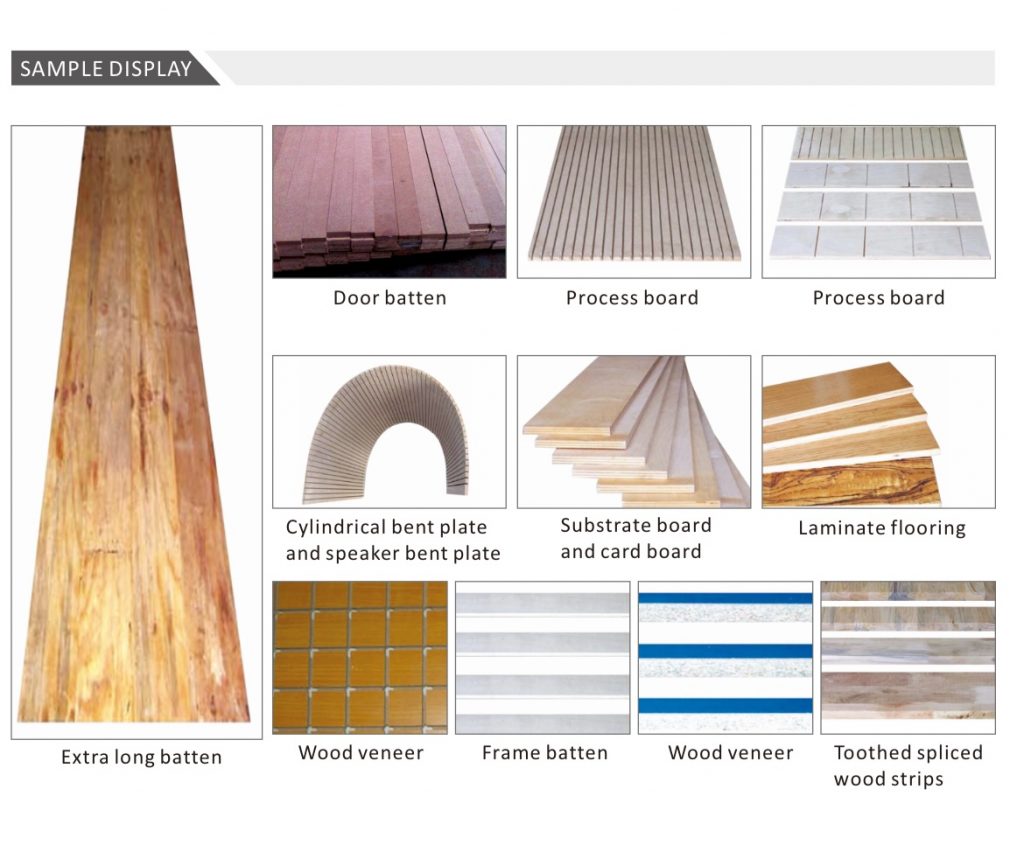

3. True Multi-Functionality for Diverse Component Needs

Your door frames aren’t one-size-fits-all—and your simple saw shouldn’t be either.

With our panel multi blade rip saw machine, you can:

- Rip wide panels into multiple strips (with the same size or multiple sizes at one time)

- Cut grooves of varying depth (perfect for decorative profiles or frame plates)

- Switch material type and size on the same line with minimal downtime

4. Built to Endure: Strong, Safe, and Low-Maintenance

All our machines are built for long-term use with:

- Wear-resistant rubber rollers for strong, smooth feeding

- Hardened roller surfaces to resist wear under high-volume use

- Auto shut-off safety system: the saw powers down instantly if the dust cover is opened

Safety and reliability are built into every detail, so your team can work confidently and your line stays running longer.

Real Results in the Real World

Hengda systems are trusted by numerous manufacturers of:

- Wooden doors and door frames

- Structural pocket linings

- Decorative trim and moldings

- Fire-rated and acoustic door components

- Flooring and panel furniture

- Wood pallets

Whether you’re supplying to real estate developers, home improvement brands, or furniture exporters, our solutions help you stay competitive, consistent, and compliant.

Next Step: Perfect Your Door Frame Production

If you’re struggling with inconsistent cuts, rising labor costs, or inflexible machinery—you don’t have to settle.

Let Hengda help you:

- Upgrade your production line

- Improve cut precision

- Lower costs and raise output

Contact us today to get a free consultation or request a custom production layout recommendation.

Visit: www.misunda.com

Call: +86-13702963227