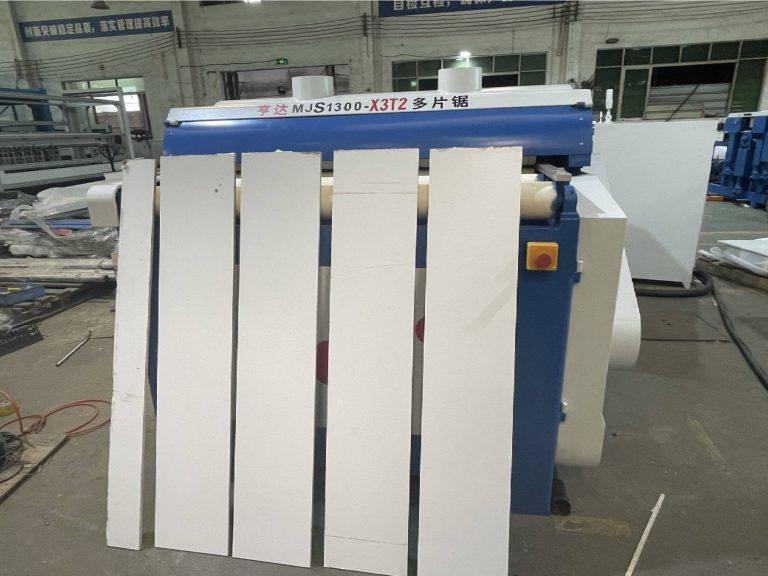

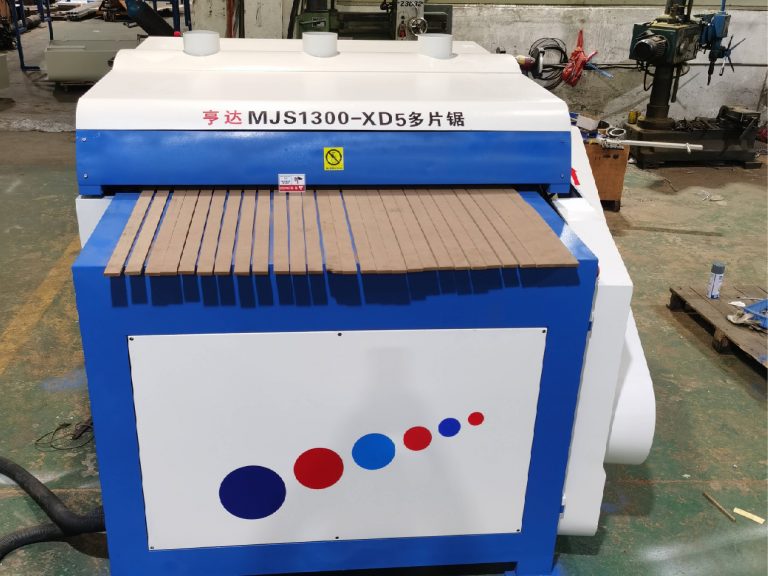

Hengda Multi-Blade Saw: Technological Synergy for Efficient, Quiet Cutting

In the woodworking industry, the pursuit of efficiency and user experience is never-ending. Previously, we shared how Hengda’s innovative spindle technology significantly…

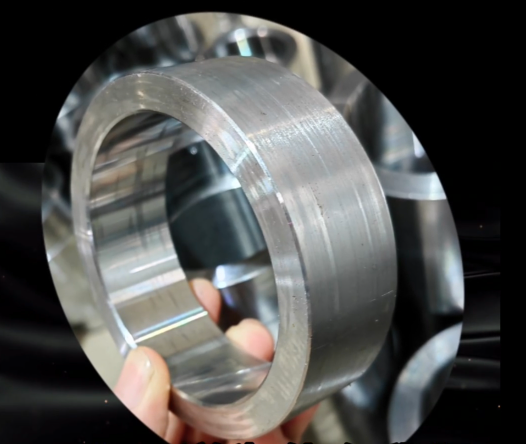

Spacers For Hengda Wood Panel Multi-Blade Saw Machine

In the precision cutting process of wood panel multi-blade saws, many factors contribute to consistently high-quality cuts. One often overlooked yet crucial…

New Technology of Multi-Blade Saw Delivers Ultra-Low Noise Operation

In the bustling environment of woodworking workshops, high-decibel machine noise is often a major concern for operators and a disruptive factor in…

Precision Casting of the Woodworking Multi Blade Saw Machine Frame

In the complex world of industrial machinery, the stability and long-term reliability of a piece of equipment often depend on its most…

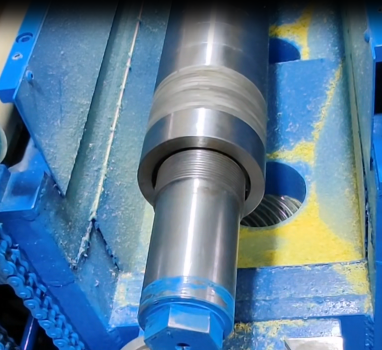

Engineering Advantages of Hengda Multi-Blade Saw Spindle

The spindle of a multi-blade saw is a critical core component that determines cutting precision and overall machine stability. Its quality and…

Ductile Iron For Multi-Blade Saw Spindle Bearing Housing

In many woodworking industrial factories, wood panel multi blade rip saw machine is very common. As a key piece of equipment in…

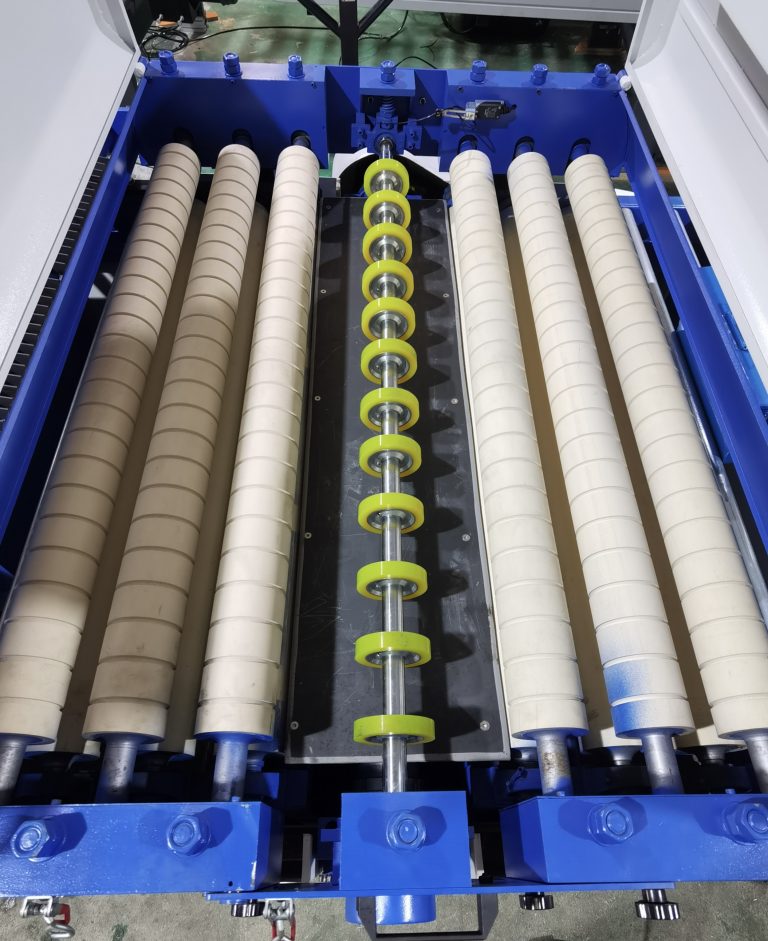

The Critical Role of Nitrile Rubber Rollers Conveyor in Wood Panel Multi-Blade Saw Machine

Conveyor rollers may seem like an inconspicuous component of a multi-blade saw machine, but they play a vital role. These rollers come…

Things to Consider When Buying a Used Multi-Blade Saw

In the wood processing industry, multi-blade saws are common equipment. For some factories, purchasing used machinery may seem like an attractive option…

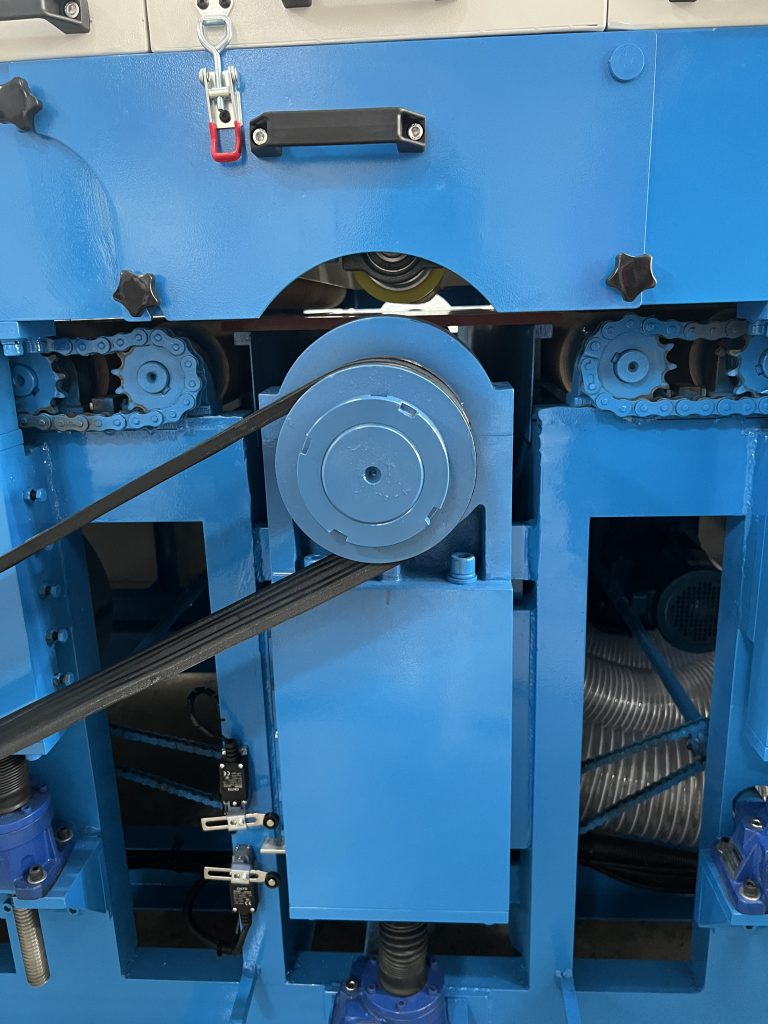

Feeding Mechanism of Multi Blade Saw Machine

As we all know, when using the wood panel multi blade rip saw machine, the power of the motors and the sharpness…