Intelligent Carton Cutting Machine With Multi-Box Types Compatibility

In today’s fast-evolving market, product varieties continue to expand, and consumer demand for personalized packaging is growing steadily. This presents new challenges for manufacturers: How can they efficiently and flexibly produce customized boxes that meet diverse size, shape, and even special functional requirements? Under traditional models, this often entails high mold costs, long lead times, and significant inventory pressure.

However, as an expert in flexible packaging lines, HENGDA understands these challenges well. Its intelligent carton cutting machine, with its exceptional multi-box compatibility, is redefining the flexibility and efficiency of packaging production, truly becoming a “packaging solution expert” for businesses.

“One-Machine-Fits-All”: A New Era of On-Demand Custom Packaging

One of the core strengths of our intelligent carton cutting machine is its ability to intelligently cut a wide variety of box types and sizes based on different product needs. Free from reliance on box factories, it leverages advanced CNC technology to realize the vision of “customized packaging—where every package is dressed in its perfect suit.”

Compatibility with International FEFCO Series

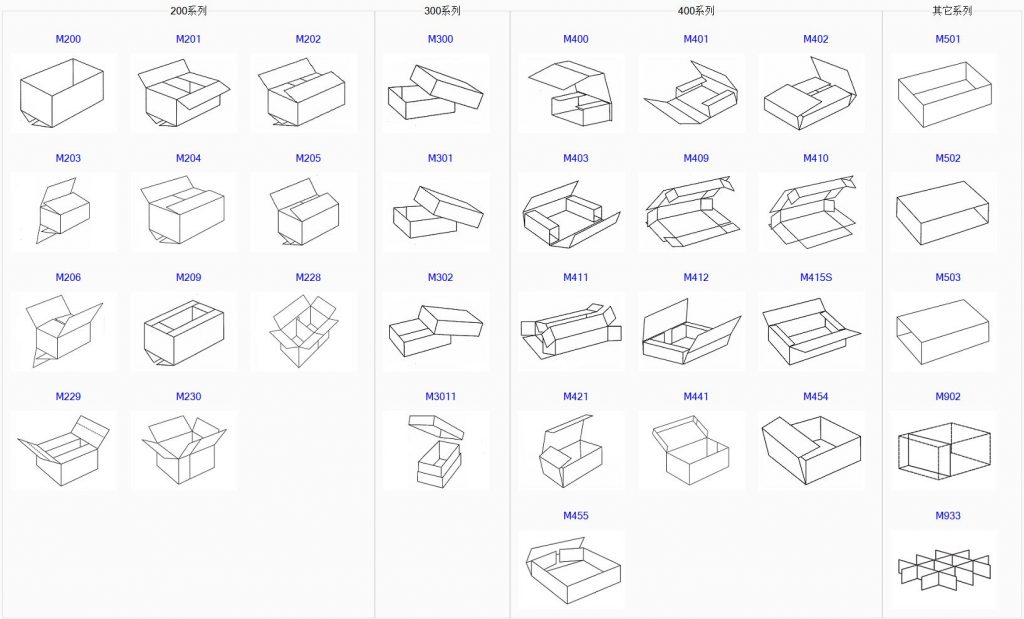

Our carton cutting machine offers extensive support for the internationally recognized FEFCO (European Federation of Corrugated Board Manufacturers) standard box types. This means everything from common shipping boxes to complex inner trays and display packaging can be effortlessly produced on a single machine. The equipment can process:

- FEFCO 200 Series: The most common slotted carton series, including various standard four-panel folding boxes and their variants. Examples include M200, M201, M202, M203, M204, M205, M206, M209, M228, M229, M230, and other basic carton styles.

- FEFCO 300 Series: Typically refers to telescopic or slide-lid boxes, such as M300, M301, M302, and M3011, providing an extra layer of protection for contents.

- FEFCO 400 Series: Includes a variety of die-cut, tray-style, or nested-structure boxes, such as M400, M401, M402, M403, M409, M410, M411, M412, M415S, M421, M441, M454, and M455. These styles are often used for product displays, delicate packaging, or internal partitions.

Additionally, our equipment supports other internationally common box types, such as FEFCO415S and FEFCO201, and can accommodate more international styles—or even non-FEFCO-standard custom boxes—based on customer requirements.

Flexible Production & Data Processing

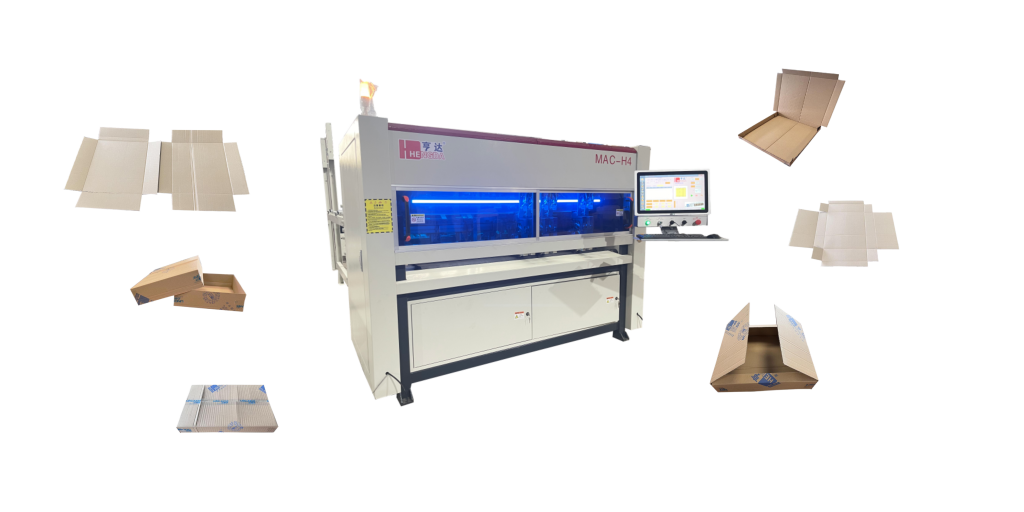

Achieving this multi-box compatibility relies on the efficient data processing capabilities of our intelligent carton cutting machine. As a highly intelligent standalone device, it can flexibly obtain box dimensions and style data from multiple sources:

- Flexible Manual Input: For small-batch, ad-hoc, or custom orders, operators can directly input carton dimensions via the machine’s control interface, and the system will instantly generate cutting instructions.

- Excel Files Import: For bulk orders with variable specifications, the machine supports Excel file imports. Users can pre-organize lists of product dimensions in the file and select the box type, and with a simple import, the machine will automate production sequentially—significantly improving data processing efficiency.

- Seamless Integration with Factory Management Systems: To achieve higher-level automation and digital management, our carton machine seamlessly connects with factory-wide management systems (e.g., ERP, MES). By scanning QR codes or barcodes on products or orders, the machine automatically retrieves the required box dimensions, enabling rapid data flow and precise production matching while minimizing manual intervention and potential errors.

Upon receiving the input dimensions and box type data, our cutting machine automatically selects the most suitable corrugated cardboard from different specifications in the silo. It then uses its patented cutting system to execute precise cuts based on the data and preset box type. This multi-source data processing and automated matching capability greatly enhances production efficiency while effectively reducing material waste.

This means that no matter how your product dimensions vary—or even if you require mixed box types for combined packaging—our carton machine can respond swiftly, enabling flexible production without mold changes. A simple system command is all it takes to switch box types.

Core Value of Carton Cutting Machine

Multi-box types compatibility delivers significant operational advantages for our customers:

- Cost Reduction: Eliminates expenses for box factories and reduces warehousing costs from excess multi-style inventory.

- Efficiency Gains: Rapid switching between box types shortens production cycles and accelerates order response times.

- Enhanced Flexibility: Easily accommodates small-batch, multi-order, and customized production needs, adapting seamlessly to market changes.

- Optimized Inventory: On-demand production drastically reduces pre-made carton stockpiles, lowering capital tied up in inventory.

- Quality Assurance: Digital control and precision cutting ensure dimensional accuracy and consistent quality for every custom box.

With its broad support for FEFCO-standard boxes, HENGDA’s intelligent carton cutting machine is more than just a high-efficiency machine—it’s a critical tool for businesses seeking packaging upgrades, cutting extra packaging costs and competitive market advantages. Choosing HENGDA means partnering with a true expert capable of delivering professional-grade solutions for all your packaging needs.