Intelligent Carton Cutting Machine: how to achieve “zero” waste precision cutting?

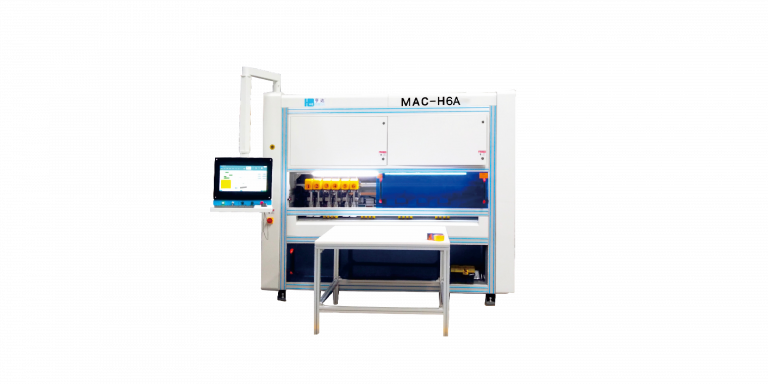

In the packaging industry, where efficiency and cost control are increasingly prioritized, material waste in carton cutting poses a significant challenge for businesses. Traditional cutting methods not only lead to material wastage but are also often accompanied by issues such as paper dust pollution and inconsistent cutting quality. However, HENGDA’s intelligent corrugated cardboard carton cutting machine is redefining industry standards with its innovative technology, delivering precise and efficient cutting with “zero” waste.

As an expert in flexible packaging lines, HENGDA understands the importance of every detail in packaging quality and cost control. The core technological highlight lies in its unique cutting system, which fundamentally addresses the pain points of traditional corrugated cardboard cutting.

Patented Cutting System of Carton Cutting Machine

Our intelligent carton cutting machine employs a patented cutting system, a key technology for achieving high efficiency and minimal waste. This system replaces traditional saw blade cutting with a disk-style flat knife.

This change in design philosophy is not just for the sake of differentiation, but is based on a deep understanding of the physical characteristics of corrugated cardboard and the actual needs of users. The unique cutting trajectory and mode of action of the disk type flat knife can achieve “precise shearing” rather than “tearing or grinding” of cardboard fibers, which fundamentally ensures the neatness and precision of the cutting edge.

Advantages of Disk-Style Flat Knives For Carton Cutting

Compared to traditional saw blades or other cutting tools that generate excessive paper dust, the disk-style flat knife offers multiple groundbreaking benefits:

- Extended Lifespan: The disk-style flat knife boasts an exceptionally long service life, significantly reducing the frequency of blade replacements and maintenance costs. This translates to longer operational uptime, fewer maintenance interruptions, lower costs and improved overall production efficiency.

- “Dust-Free” Cutting and Creasing for Corrugated Cardboard: This is a major breakthrough for our intelligent cutting machine. It achieves “dust-free” creasing and cutting during corrugated cardboard processing, drastically reducing or even eliminating paper dust, fine fiber fragments, and powder generated during cutting. Traditional cutting methods often produce substantial paper dust due to friction and tearing during high-speed cutting. This technology eliminates this issue, rendering complex vacuum dust extraction systems unnecessary. This not only significantly improves the working environment and safeguards operators’ respiratory health but also reduces wear and tear on equipment caused by paper dust. Additionally, it ensures the cleanliness of the cut cardboard, preventing contamination of the final packaged products—a critical feature for industries with stringent hygiene requirements, such as food and electronics.

- Smooth Cutting Edges: Corrugated cardboard cut with the disk-style flat knife features exceptionally smooth, burr-free edges. This ensures a more aesthetically pleasing and structurally stable finished carton while minimizing the risk of tearing or damage caused by rough edges.

- Constant-Gap Fracture Cutting: The system utilizes constant-gap fracture cutting technology, ensuring no contact between the cutting blade and the all-steel backing plate. This further extends the cutting tool’s lifespan and guarantees consistent, high-precision cutting.

Reducing Waste For Carton Cutting

Beyond advanced cutting hardware, our intelligent carton cutting machine incorporates software-level optimization. The machine automatically calculates the most economical paper dimensions for processing. This means the system intelligently selects the optimal corrugated cardboard specifications based on the carton size to maximize raw material utilization, thereby minimizing unnecessary waste at the source and truly approaching the goal of “zero” waste.

Continuous, High-Efficiency Automated Production

Our intelligent carton cutting machine can process corrugated cardboard continuously and efficiently, with slotting and creasing performed simultaneously. This synchronous processing capability greatly enhances production efficiency and shortens processing cycles. And this superior cutting performance ensures completely burr-free edges, guaranteeing high product quality.

Conclusion

Our intelligent corrugated cardboard carton cutting machine, through its patented disk-style flat knife cutting system, genuine “dust-free” operation tailored to cardboard characteristics, smooth edges, and intelligent material optimization, not only significantly improves cutting efficiency and quality but also minimizes material waste to the greatest extent. For businesses pursuing lean production and sustainable development, choosing HENGDA’s intelligent carton cutting machine is undoubtedly a crucial step toward an efficient, eco-friendly, and near “zero” waste future in smart packaging.