Improving Wood Cutting Efficiency: Why the Wood Panel Multi Saw Machine is the Best Choice

In the wood processing industry, cutting efficiency plays a critical role in determining overall productivity. With increasing demands for high-quality wood products, manufacturers face the challenge of boosting production speed, reducing waste, and maintaining cutting precision. This is where the wood panel multi saw machine comes into play. In this article, we’ll explore why the wood panel multi saw machine is the best choice for improving wood cutting efficiency and how it can revolutionize your production line.

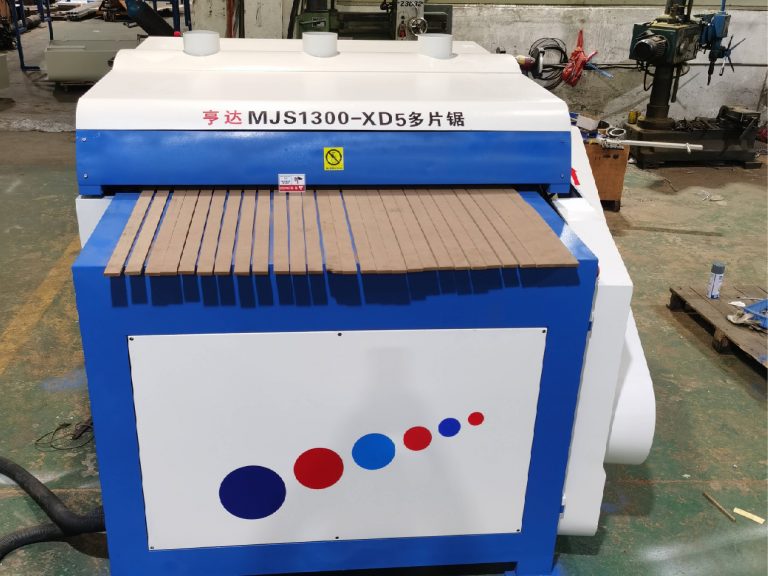

What is a Wood Panel Multi Saw Machine?

A wood panel multi saw machine is a high-efficiency cutting tool designed to simultaneously cut wood panels into multiple sections in a single operation. Unlike traditional single-blade saws, which can only cut one piece at a time, the wood panel multi saw machine uses multiple blades working in tandem, drastically improving cutting speed and precision.

Boosting Production Efficiency with the Wood Panel Multi Saw Machine

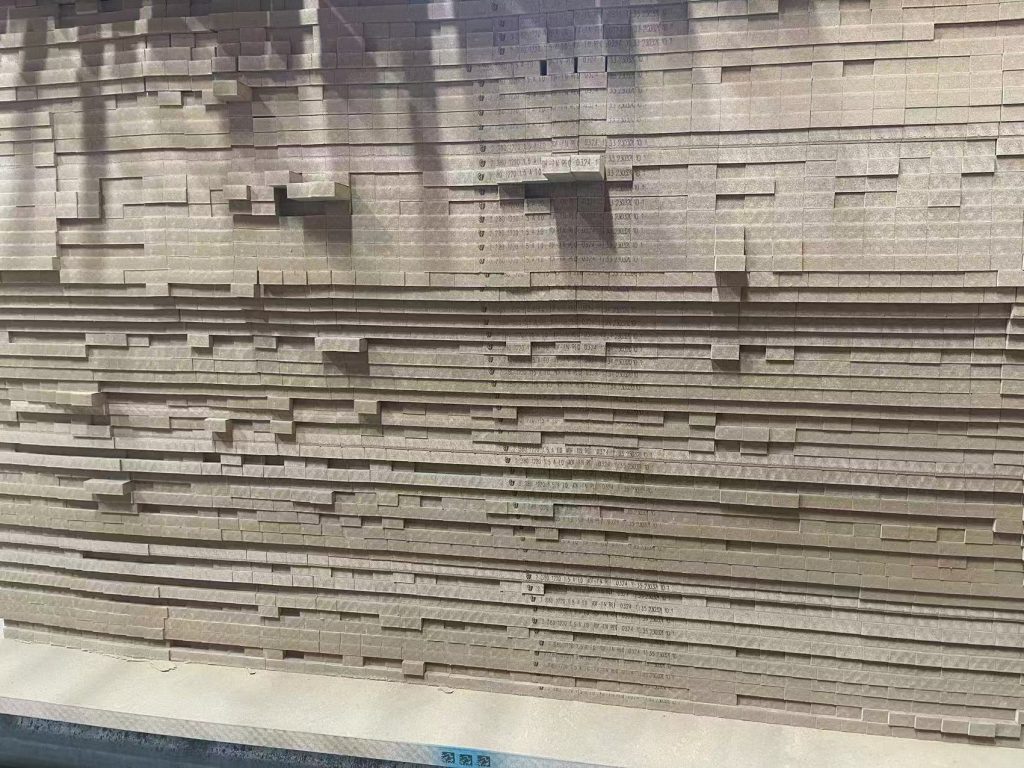

The primary advantage of using a wood panel multi saw machine is its ability to handle multiple cuts simultaneously. By utilizing multiple blades, this machine can efficiently cut wood panels into several pieces in one pass. This ability to process multiple panels at once drastically reduces processing time and increases output, making it ideal for high-volume wood cutting tasks.

- Multiple Cuts at Once: The wood panel multi saw machine allows manufacturers to cut multiple pieces of wood in one go, significantly reducing cycle times and increasing throughput.

- Faster Production Times: With multiple saws working simultaneously, the overall production speed increases, which is especially beneficial in large-scale operations that require high output.

Precision and Consistency with Minimal Waste

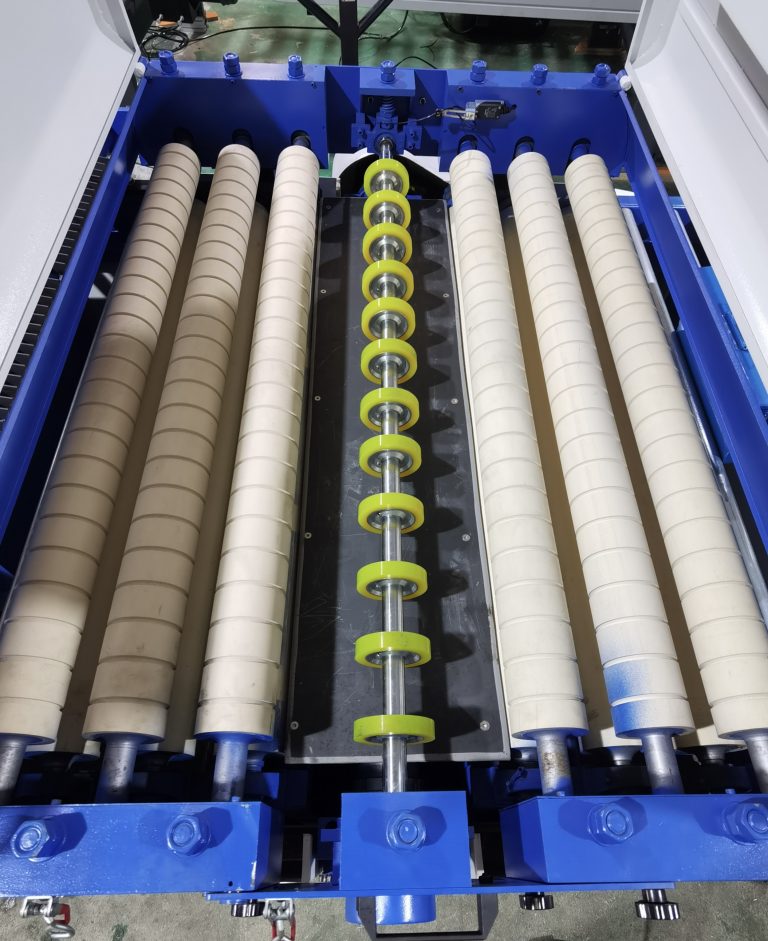

Precision is a critical factor in wood cutting, especially when working with materials like MDF, plywood, or solid wood, where exact dimensions are necessary. The wood panel multi saw machine is optional with servo motors that control each saw blade’s position with high precision, ensuring that every cut is consistent and accurate.

- High Cutting Precision: The wood panel multi saw machine ensures consistent cutting dimensions for each panel, maintaining high quality across large production batches.

- Reduced Material Waste: With precise cuts, less material is wasted, improving material yield and reducing costs. This is particularly advantageous for manufacturers focused on sustainability and reducing material waste.

Flexibility in Cutting Configuration

One of the standout features of the wood panel multi saw machine is its ability to adjust blade configurations. Depending on the production needs, the machine can be customized to cut wood panels into various sizes and thicknesses. This flexibility makes it adaptable for a wide range of applications, from furniture manufacturing to flooring production.

- Customizable Cutting Width: The spacing between the blades can be adjusted to accommodate different widths, giving manufacturers the flexibility to meet varying production requirements.

- Versatile Applications: Whether you’re cutting solid wood, plywood, or MDF, the wood panel multi saw machine can handle a wide range of materials, making it an invaluable tool in diverse industries.

Energy Efficiency and Cost Reduction

As energy costs continue to rise, reducing energy consumption becomes increasingly important for manufacturers. The wood panel multi saw machine is designed with energy-efficient motors and cutting systems that minimize power usage without sacrificing performance. By optimizing energy consumption, this machine can lower operational costs while still providing the necessary cutting power.

- Energy-Efficient Operation: The wood panel multi saw machine uses less power than traditional saws, making it an environmentally friendly option for manufacturers seeking to reduce their carbon footprint.

- Lower Operational Costs: The efficiency of the machine not only reduces energy consumption but also lowers maintenance costs, further enhancing its cost-effectiveness in the long run.

Automation for Greater Efficiency

Modern wood panel multi saw machines are often equipped with automated features that further streamline the cutting process. Features like automatic feeding systems, blade adjustments, and real-time monitoring improve overall operational efficiency. Automation also reduces the need for manual intervention, which helps to decrease labor costs and minimize human error.

- Automated Feeding Systems: The machine can automatically feed the wood into the cutting area, improving workflow and minimizing delays.

- Automatic Blade Adjustments: Many advanced models come with automated systems that adjust the blade positions based on the material being cut, ensuring maximum efficiency and precision.

Dual-Spindle Design for Simultaneous Cutting and Slotting

Some models of wood panel multi saw machines, like the HD1300-XT2L, feature a dual-spindle design, allowing for simultaneous cutting and slotting operations. This two-in-one functionality enables manufacturers to perform more complex operations with a single machine, further enhancing production efficiency.

- Simultaneous Cutting and Slotting: The HD1300-XT2L can simultaneously cut and slot wood panels, which reduces the number of processes required and increases production efficiency.

- Ideal for Complex Operations: This dual-spindle design is especially beneficial for industries that require more advanced cutting operations, such as custom furniture makers and flooring manufacturers.

Why Choose the Wood Panel Multi Saw Machine?

If you’re looking to improve your wood cutting efficiency, the wood panel multi saw machine is the ideal choice. It offers:

- Higher throughput with multiple blades working at once.

- Greater precision in cutting, reducing waste and improving material yield.

- Flexibility to meet diverse production requirements.

- Lower energy consumption and reduced operating costs.

- Advanced automation for higher efficiency and reduced labor costs.

For businesses looking to enhance their cutting processes, reduce operational costs, and increase production speeds, the wood panel multi saw machine is the best choice. Whether you’re working with solid wood, plywood, MDF, or other materials, this machine will provide the precision and efficiency you need to stay competitive in the market.