How to Maintain a Corrugated Cardboard Box Cutting Machine for Long-Term Efficiency

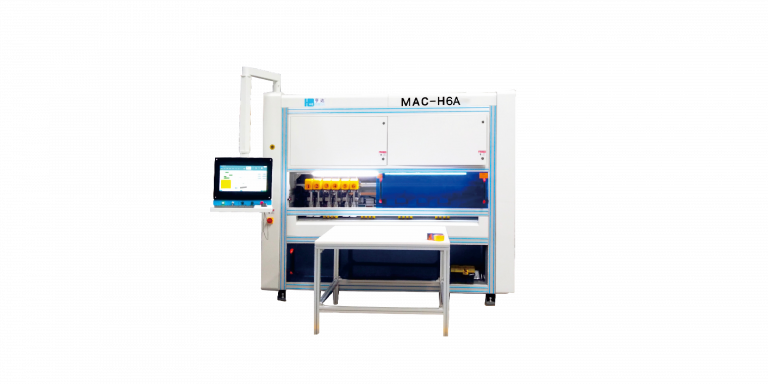

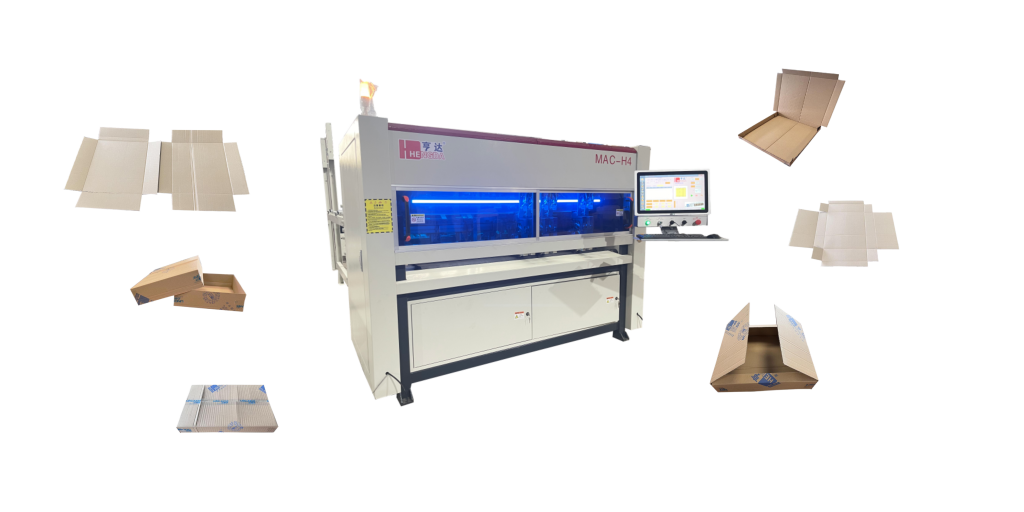

Investing in a corrugated cardboard box cutting machine is a smart move for factories looking to reduce packaging costs, improve flexibility, and produce cartons on demand. However, just like any industrial equipment, proper maintenance is essential to keep the machine running smoothly and to maximize its lifespan.

In this article, we’ll explore best practices for maintaining a corrugated cardboard box cutting machine so your factory can enjoy consistent performance and long-term efficiency.

Why Maintenance Matters for a Corrugated Cardboard Box Cutting Machine

Neglecting maintenance can lead to:

- Reduced cutting precision

- Frequent downtime

- Higher energy consumption

- Increased repair costs

On the other hand, a well-maintained corrugated cardboard box cutting machine can deliver:

- Stable, accurate carton cutting

- Longer equipment lifespan

- Lower operational costs

- Higher productivity with fewer interruptions

Daily Maintenance Checklist for a Corrugated Cardboard Box Cutting Machine

1. Clean the Cutting Area

Dust and cardboard scraps can accumulate in the cutting zone. Daily cleaning prevents blockages, protects the blades, and ensures precision.

2. Inspect Blades and Cutting Tools

Blunt blades reduce efficiency and cause uneven cuts. Check blade sharpness regularly and replace or sharpen when needed.

3. Check the Feeding System

The feeding rollers and belts should be inspected daily to ensure smooth cardboard movement without jams.

Weekly and Monthly Maintenance for a Corrugated Cardboard Box Cutting Machine

Weekly Tasks

- Lubricate moving parts such as rails and bearings

- Test emergency stop functions for safety

- Inspect sensors to ensure accurate carton measurement

Monthly Tasks

- Check software updates for machine control systems

- Inspect alignment and calibration for cutting precision

- Review machine logs to track performance trends

Long-Term Care for a Corrugated Cardboard Box Cutting Machine

1. Schedule Professional Servicing

At least once or twice a year, bring in certified technicians to conduct a full inspection.

2. Train Operators Regularly

A well-trained team reduces misuse and prevents unnecessary wear.

3. Replace Worn-Out Parts Promptly

Proactive part replacement avoids sudden breakdowns and costly downtime.

Conclusion

A corrugated cardboard box cutting machine is a major investment that can revolutionize your packaging process. To protect this investment, factories must implement a structured maintenance routine that includes daily cleaning, weekly lubrication, monthly calibration, and annual professional servicing.

By taking care of your machine, you ensure:

- Consistent carton quality

- Reduced downtime

- Lower repair costs

- Extended equipment lifespan

In the long run, proper maintenance is not just about protecting your corrugated cardboard box cutting machine—it’s about protecting your factory’s efficiency, reputation, and profitability.