How a Corrugated Cardboard Box Cutting Machine Transformed a Furniture Factory

In the furniture industry, packaging has always been a challenge, especially for ready-to-assemble cabinets. Products come in different sizes, making it difficult to find the right carton every time. For one furniture factory, this struggle seemed endless—until they discovered the power of a corrugated cardboard box cutting machine. This is their story.

The Daily Struggles with Traditional Carton Procurement

Every day, workers completed wardrobes, cabinets, and shelves only to face the same frustrating scenario: the workers were cutting the cardboard by hand to pack the products one by one, wasting a lot of time. Oversized packaging boxes were common, padded with filler material to keep furniture safe.

The consequences were serious:

- Cardboard waste piled up because too much material was used.

- Shipping costs increased as larger boxes took up more space in trucks.

- Wasting a lot of time and labor to cut the cardboard one by one manually, leading to low efficiency.

What was meant to be a smooth packaging process became a bottleneck that slowed the entire production line.

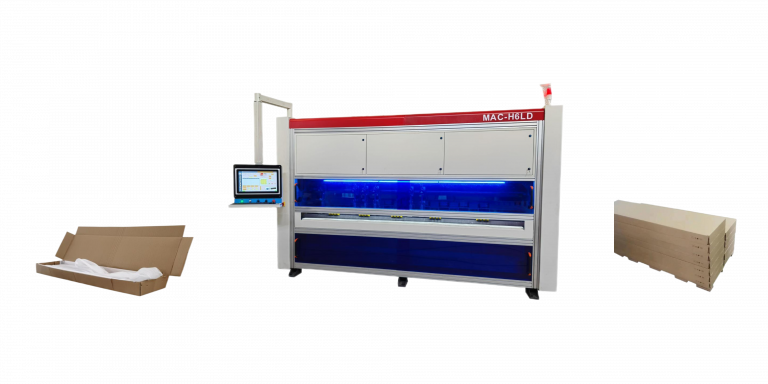

The Turning Point: Introducing a Corrugated Cardboard Box Cutting Machine

The factory’s management knew something had to change. That’s when they invested in a corrugated cardboard box cutting machine. Unlike traditional procurement, this machine could create cartons on demand, perfectly sized for each product.

Now, when a wardrobe rolled off the assembly line, workers entered its dimensions into the machine. Within minutes, a customized carton was ready—no oversized packaging, no extra filler materials, and no delays. The warehouse, once crowded with cartons, suddenly had space for more valuable operations.

The Impact on Costs and Efficiency

The transformation was immediate and measurable:

- 40% less cardboard waste thanks to precision cutting.

- Lower logistics costs as right-sized cartons improved truckload efficiency.

- Faster packaging times, since workers no longer searched for the “closest fit” box.

- Improved customer satisfaction, as buyers received furniture in sleek, well-fitting cartons.

The corrugated cardboard box cutting machine quickly proved it was not just an expense—it was an investment that paid for itself in less than 14 months.

A New Way of Thinking About Packaging

For the factory, the machine became more than just a piece of equipment. It marked the beginning of a new approach to packaging—one that was efficient, sustainable, and customer-focused. No longer trapped by carton inventory and unnecessary waste, the business gained control over its packaging process.

The corrugated cardboard box cutting machine turned packaging from a burden into a competitive advantage.

Conclusion

This story is just one example of how a corrugated cardboard box cutting machine can reshape manufacturing operations. By eliminating waste, reducing storage, and improving logistics, the machine doesn’t just cut cardboard—it cuts costs, inefficiencies, and frustration.

For factories facing the same struggles, adopting a corrugated cardboard box cutting machine could be the turning point that transforms packaging into a strength rather than a weakness.