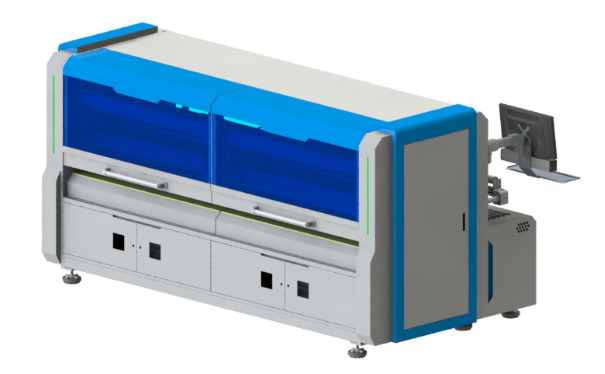

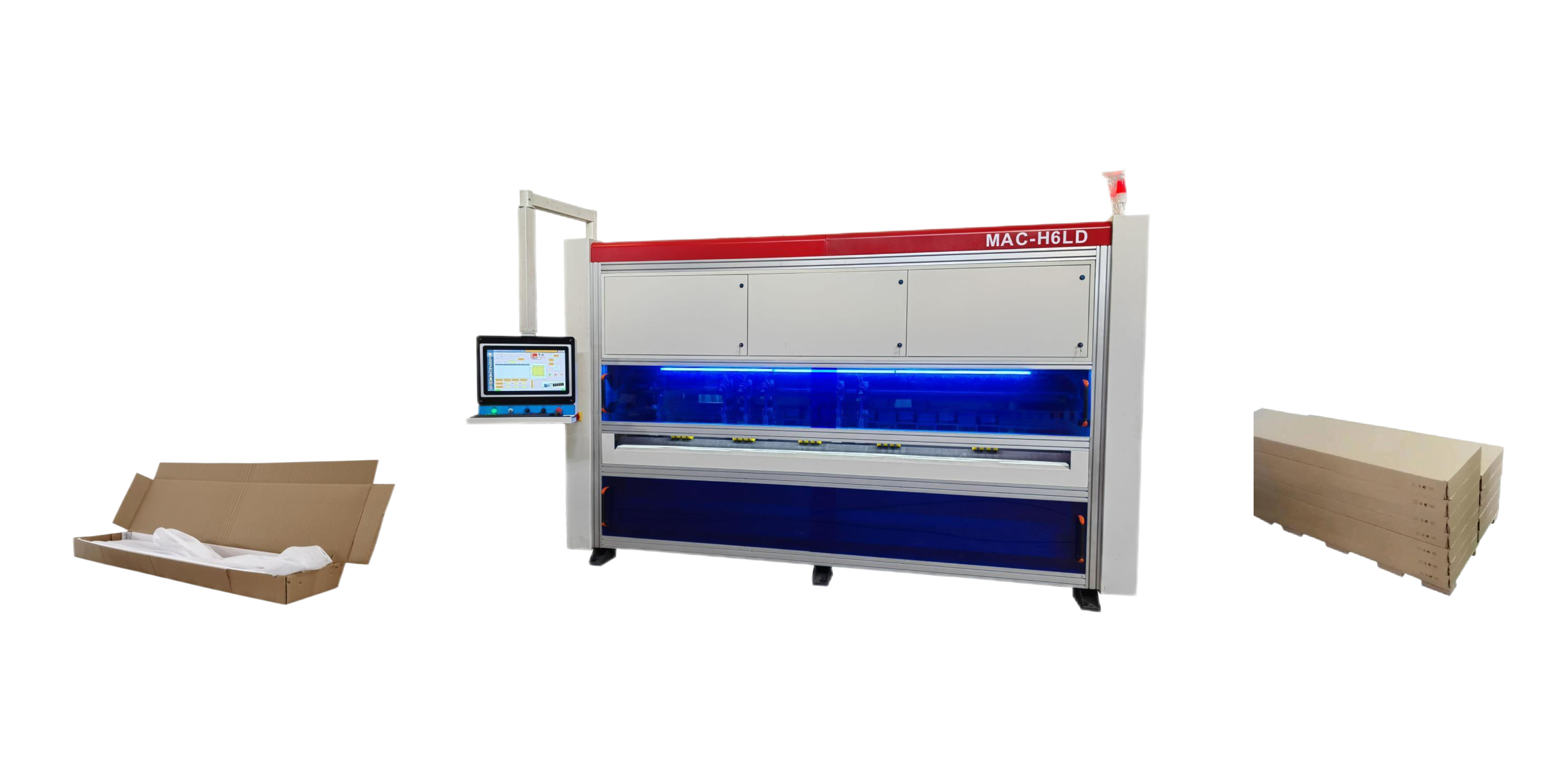

Hengda Intelligent Box Making Machine with Efficient & Precise Packaging

In modern intelligent packaging production, the “box making machine” – in Hengda’s context, the equipment responsible for precision cutting of corrugated boards and completing fundamental preprocessing – serves as the cornerstone of the entire packaging process. It is not merely a traditional machine that folds paperboards into shape, but rather establishes a foundation of high quality and efficiency for the final cartons through its exceptional performance. The Hengda Intelligent Box Making Machine (i.e., carton cutting machine), with its innovative technology, has completely transformed traditional carton cutting methods, becoming a core solution for enterprises to achieve efficient, flexible, and low-waste packaging production.

Pain Points of Manual Box Making

For a long time, reliance on manual labor for carton cutting and preprocessing has been a common challenge for packaging enterprises:

Low Production Efficiency

Manual cutting is slow, struggling to meet large-volume orders, severely dragging down overall packaging production rhythm.

Significant Cutting Errors

Limited precision in manual operations easily leads to dimensional deviations in paperboards, affecting final carton quality and increasing material waste and defect rates.

High Labor Costs

Cutting is labor-intensive, requiring substantial manpower, leading to soaring labor costs and difficulties in recruitment.

Excessive Material Waste

Inaccurate cutting or suboptimal layouts generate excessive scrap, increasing raw material costs.

These pain points urgently call for intelligent, efficient automated solutions.

Advantages of Box Making Machine

Designed to address these challenges, our Intelligent Box Making Machine (carton cutter) elevates cutting to new heights of intelligence, precision, and efficiency, laying a solid foundation for final carton forming:

Precision Cutting & Superior Quality

- Performs simultaneous cutting and creasing, ensuring both cutting lines and fold lines are completed in one operation.

- Delivers sharp contours, flawless edges (burr-free), guaranteeing smooth folding and perfectly squared cartons.

Ultimate Flexibility & Smart Material Management

Multi-Brand Paper Compatibility

- Processes paper from various suppliers, eliminating single-supplier dependency and optimizing procurement costs.

Multi-Spec & Multi-Layer Cutting

- Handles 2-layer (roll), 3-layer, and 5-layer (continuous sheet) corrugated boards with a max width of 2500mm per rack.

12-silo Auto-Switching

- Stores 12 paper specs simultaneously, with auto-calibration for minimal waste.

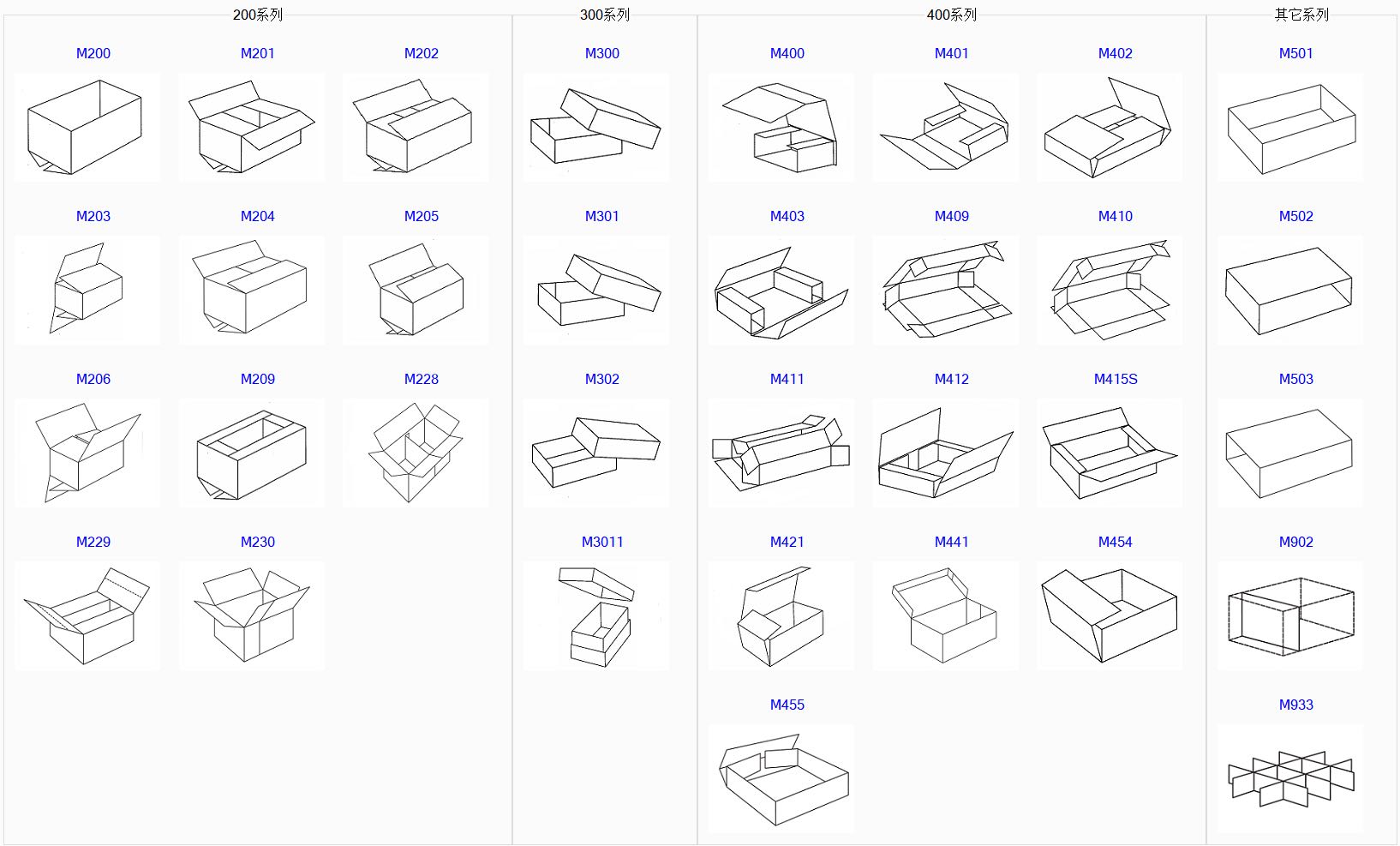

30+ International Carton Styles

- Preloaded designs cater to diverse industries, enabling rapid response to custom orders.

Continuous Processing Mode

- Uninterrupted workflow for high-volume output.

4-10 Pieces/Minute

- 4× faster than manual cutting, ensuring efficient production capacity.

Tangible Benefits for Enterprises

Deploying our solution directly addresses traditional pain points:

Cost Reduction

- Lower material waste (optimized cutting) + 60% labor savings (automation).

Efficiency Leap

- Faster turnaround = improved market responsiveness.

Quality & Flexibility

- 30+ carton styles + multi-material compatibility = agile production.

Competitive Edge

- Combines cost control, speed, and quality to dominate markets.

Conclusion

The Hengda Intelligent Box Making Machine (carton cutting machine) is the “engine” and “precision hand” of modern smart packaging lines. With its cutting-edge accuracy, unmatched material adaptability, 30+ carton designs, and cost-saving efficiency, it eradicates traditional bottlenecks. For enterprises pursuing efficiency, quality, and flexibility, investing in Hengda means choosing a path to intelligent manufacturing—a strategic move to boost competitiveness and achieve lean production.