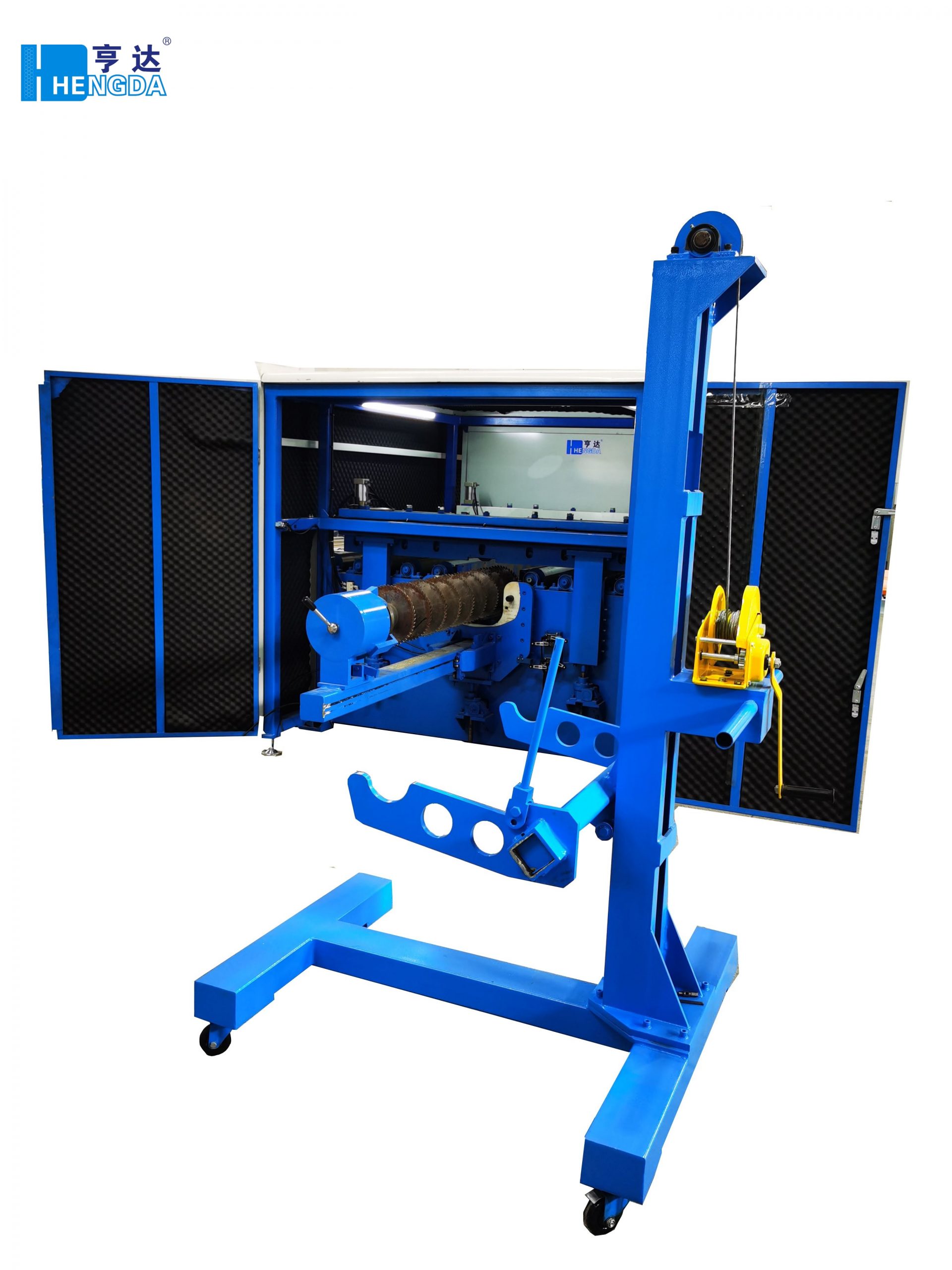

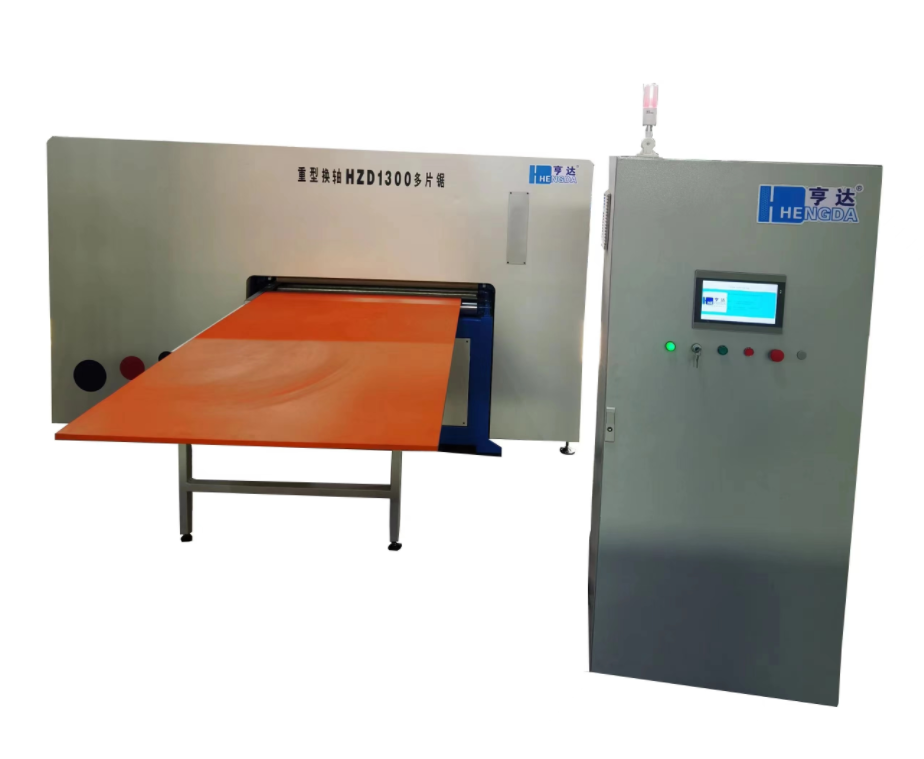

Hengda HDZ1300 Quick Shaft Change Multi-Blade Saw Machine

In many wood processing industries, like flooring, wood pallet, downtime is costly. Every minute your equipment isn’t running translates into lost revenue, delayed orders, and higher labor costs. For wood material cutting, one of the most common sources of downtime in rip saw operations is the time-consuming process of changing saw blades to fit with different cutting sizes.

To address this challenge, Hengda introduces the HDZ1300 Shaft Changable Multi-Blade Saw Machine—a high-performance solution designed to dramatically reduce blade change time, enhance conveying reliability, and support high-volume, precise cutting applications. Whether you’re manufacturing furniture components, door frames, or composite panels, this machine helps you stay ahead by cutting more efficiently, safely, and flexibly.

The Hidden Cost of Downtime in Wood Cutting Operations

For many manufacturers, the traditional method of changing saw blades involves:

- Multiple operators to take out and put in the blades one by one

- Several minutes (or even hours) of machine stoppage

This interrupts production flow, adds unnecessary labor, and increases the risk of improper installation. Worse, these delays compound over time, reducing your plant’s daily output and profitability.

How the HDZ1300 Quick Shaft Change Device Works

Unlike traditional multi blade saws—where the operator must remove each saw blade and spacer manually on a fixed shaft—the Hengda HDZ1300 uses a fully removable shaft system that enables much faster and safer changeovers.

Here’s how it works:

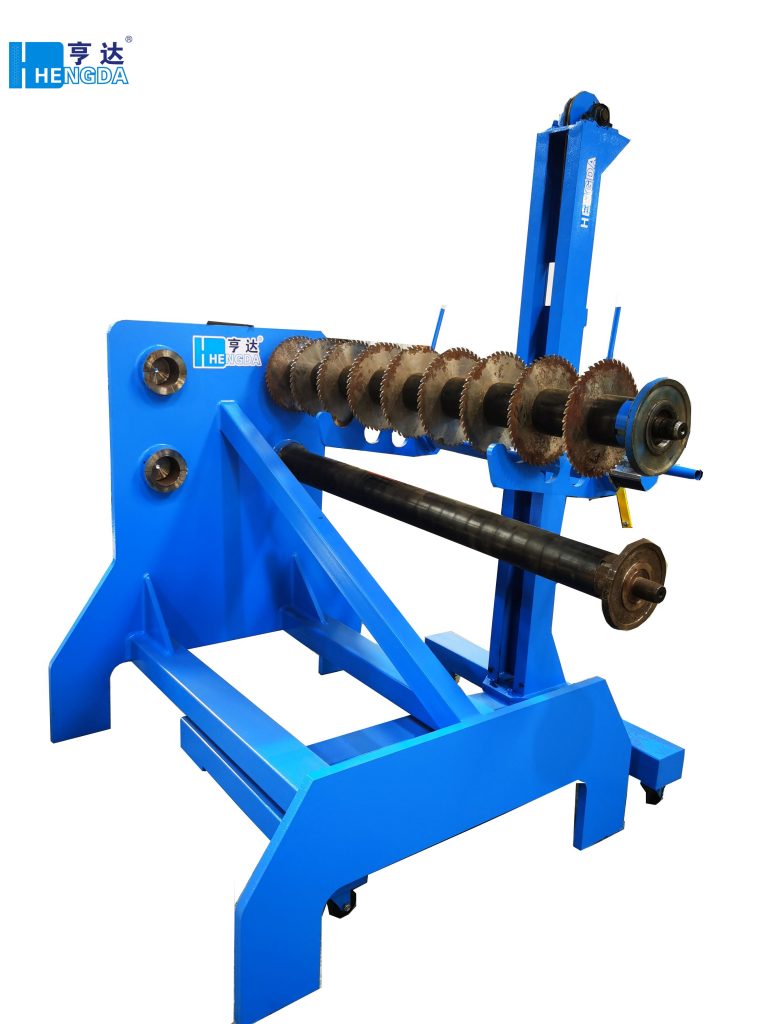

- The HDZ1300 is equipped with interchangeable spindle shafts.

- Instead of disassembling blades one by one, the entire spindle (with pre-arranged saw blades and spacers) can be pulled out as a single unit.

- A second spindle—already assembled off the machine with a different blade layout—is then inserted.

- The operator locks the new shaft in place, and the machine is ready for operation within minutes.

This system significantly reduces setup time, minimizes handling errors, and ensures more consistent cutting accuracy across different product specifications.

In contrast, traditional machines require operators to work directly on the shaft, manually removing and reinstalling each blade and spacer—an error-prone and time-consuming process.

The HDZ1300’s shaft-swap approach brings both speed and repeatability, making it ideal for high-throughput operations with varying cutting needs.

Built for Continuous Production: Dual Roller Conveying System

Beyond quick-change capability, the HDZ1300 is equipped with a powerful upper and lower roller feed system. This design delivers superior grip and control, allowing boards to move through the cutting zone smoothly, quickly, and accurately.

Advantages of This Conveying System:

- Strong clamping force reduces slippage

- Suitable for both lightweight and heavy panels

- Improves operator safety at high feed speeds

- Ensures consistent cutting accuracy

Built to Handle a Wide Range of Materials and Applications

The HDZ1300 isn’t just fast—it’s flexible. It processes a variety of wood materials, including:

- Solid wood planks

- MDF and particleboard

- Laminated and composite materials

- Any other wood materials

You can use the HDZ1300 for:

- Straight ripping

- Grooving to fixed depths

- Customized width adjustment (with compatible blade configurations)

This versatility makes the machine ideal for:

- Furniture production

- Wooden door and window manufacturing

- Structural wood preparation

- Decorative molding cutting

Technical Specifications of HDZ1300

| Parameter | HDZ1300 Specification |

|---|---|

| Max Processing Width | 1200 mm |

| Processing Thickness | 5–50 mm |

| Min Processing Length | 600 mm |

| Spindle Diameter | 80 mm |

| Spindle Speed | 2600 m/min |

| Saw Blade Size | 255 × 80 × 3.0 × 48T |

| Main Motor Power | 45 kW |

| Feed Speed | 0–35 m/min (Inverter Controlled) |

| Machine Dimensions | 2000 × 3300 × 1850 mm |

What You Can Get

- 50%-70% less time spent on blade changes

- Higher daily output with the same labor force

- Lower maintenance risk due to streamlined blade design

- Greater adaptability to custom orders and changing product lines

Whether you’re producing long runs of flooring substrate or small-batch cabinet parts, the HDZ1300 helps you achieve more consistent results with less downtime.

Difference With HDZ1300 vs. MJSD-HT4

When choosing between the HDZ1300 Quick Shaft Change Multi-Blade Saw and the MJSD-HT4 Servo-Adjustable Multi-Blade Saw, it’s important to understand the core strengths of each model.

- The MJSD-HT4 excels in blade spacing automation, enabling ultra-fast, servo-driven width adjustments via PLC control. However, due to its servo mechanism structure, it cannot cut very narrow strips—its minimum blade spacing is limited (typically to 190–265mm depending on configuration).

- In contrast, the HDZ1300, while not as fast in blade spacing adjustment, with manual shaft change and allows cutting of narrow strips with flexible spacing, making it ideal for applications like wooden crate slats, narrow flooring components, and packaging panels.

Conclusion

The Hengda HDZ1300 Shaft Changable Multi-Blade Saw is more than a machine—it’s a productivity tool designed for the demands of modern wood cutting processing. By combining speed, safety, and versatility, it provides manufacturers with a powerful solution to reduce bottlenecks, minimize maintenance downtime, and respond quickly to shifting production needs.

Interested in learning more? Contact us today for a personalized quote or demo video, and see how the HDZ1300 can upgrade your cutting line.