Hengda Box Making Machine: Precision Box Cutting Packaging

In modern intelligent packaging production lines, every step is critical, and the efficiency and precision of the “box making” process often begin with an exceptional box making machine. Hengda’s box making machine is not merely a cutting tool—it acts as the “designer” and “cornerstone” of the smart box-making process, laying a high-quality foundation for the final carton with its outstanding performance. We can regard the Hengda box making machine as the starting point of “box making machine → carton forming machine” because it directly determines the precision and efficiency of box assembly.

Box Making Machine: Intelligent Step in Carton Production

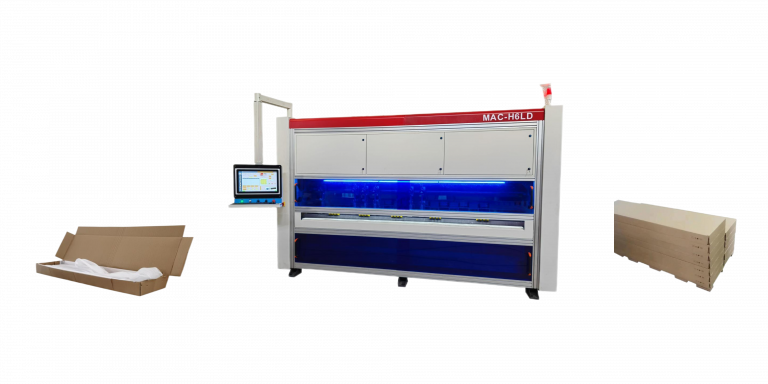

A flawless carton begins with precision cutting. Our box making machine takes on this crucial task, offering not just cutting but also pre-processing capabilities essential for box making:

Simultaneous Cutting & Creasing

- Performs cutting and creasing (folding lines) in one operation.

- Ensures clean, standardized creases, critical for automated folding into perfect “block-style” cartons.

Sharp Contours & Superior Cutting

- Advanced control systems guarantee smooth, burr-free edges.

- Prevents jams or deformations in later production stages, ensuring seamless workflow.

Thus, our box making machine doesn’t just cut—it pre-structures the carton, making it the first intelligent step in box production.

Material Optimization for Box Making

To meet diverse market demands, the flexibility and material management of a box making machine directly impact efficiency and costs. We excels in this aspect:

Multi-Brand & Multi-Spec Compatibility

- Processes different paper brands, reducing supplier dependency.

- Supports multiple paper specs on material racks, including 2500mm-wide corrugated boards, maximizing material utilization.

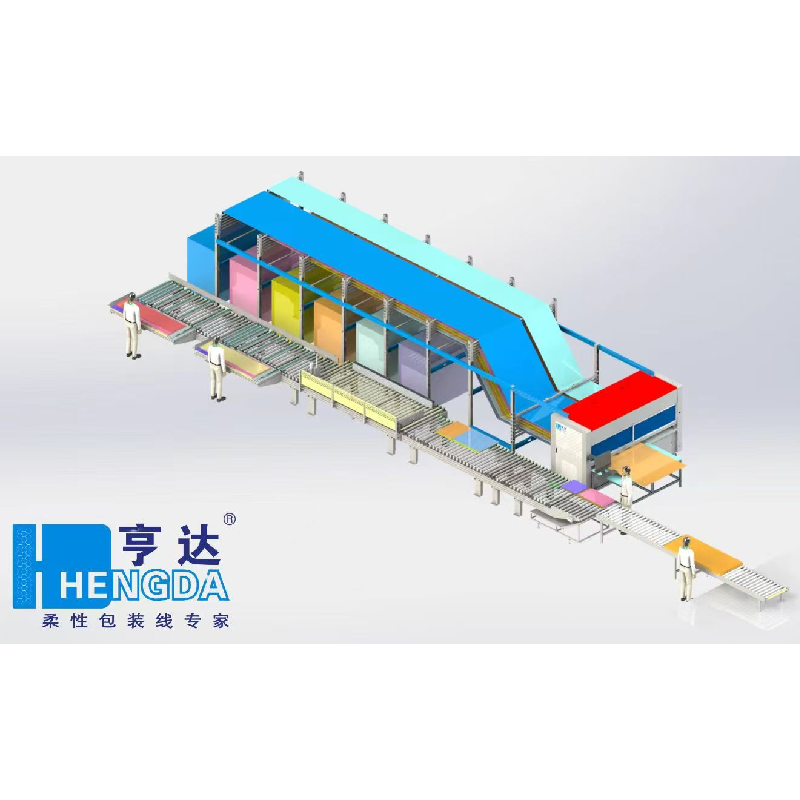

12-Spec Smart Silo System

- 12 silos allow automatic switching and calibration for minimal paper waste.

- Handles 2-layer, 3-layer, and 5-layer corrugated boards seamlessly.

Boosting Efficiency & Cutting Costs at Box Making

Our box making machine delivers root-level improvements in efficiency and cost control:

High-Speed Production (4-10 pieces/minute)

- Continuous processing ensures uninterrupted material supply for downstream box forming.

Reduced Material Waste & Costs

- Precision cutting lowers paper loss rates, translating to significant cost savings.

Conclusion

Hengda box making machine is far more than a cutter—it’s the intelligent foundation of carton production. By delivering perfectly pre-cut boards, it empowers automated forming and sealing, helping businesses achieve high-efficiency, high-quality, and low-cost modern packaging.