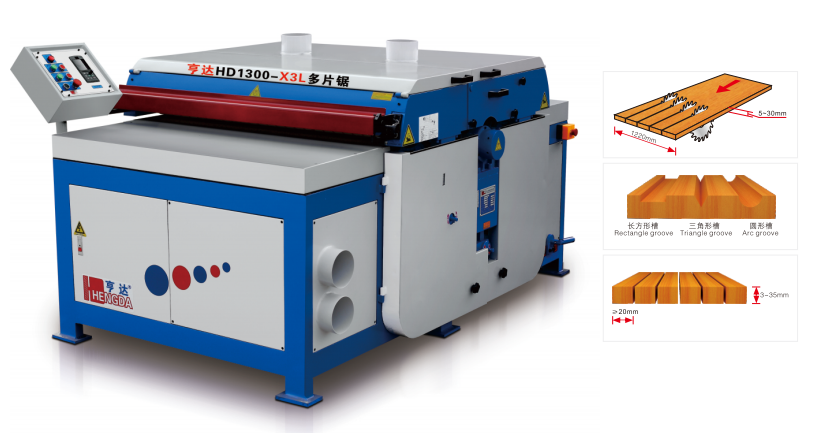

HD1300 Gang Rip Saw Machine For Wood Processing Efficiency

The HD1300 Gang Rip Saw Machine is redefining standards in wood processing with three times the productivity and millimeter-level precision. Designed for 24/7 heavy-duty operation, it integrates a military-grade power system, smart energy-saving technology that reduces power consumption by 35%, and a triple safety system that lowers accident rates by 90%. It’s the ideal solution for manufacturers in furniture, construction materials, wood packaging, and flooring.

Engineered for Performance: Introducing the HD1300 Series

Innovation That Sets a New Standard

Built to deliver exceptional speed and accuracy, the HD1300 Gang Rip Saw Machine represents a major upgrade for manufacturers seeking to scale output without sacrificing cut quality. Its robust engineering, advanced control systems, and streamlined design make it a trusted asset across wood processing industries.

Technical Lineup

The HD1300 series includes models such as HD1300-X3L, HD1300-XD3L, HD1300-XD4L, and HD1300-XT2L—each designed to meet varying performance and budget requirements while maintaining industry-leading results in throughput and precision.

Backed by Technology & Trust

A Proven Manufacturer

HENGDA is the earliest innovators in gang rip saw technology in China and holds multiple patents for multi-blade saw design and automation. As a manufacturer with ISO9001 certification and CE compliance, we bring over 20 years of innovation, including the development of servo-controlled blade adjustment and automatic spindle switching.

International Standards Compliance

Our machines meet global benchmarks for quality and safety. All HD1300 series saws are CE certified and built under a fully ISO-compliant quality system.

What Makes HD1300 Gang Rip Saw Machine Stand Out?

Triple Safety System

To ensure workplace safety, the HD1300 is equipped with:

- A fully enclosed protective cover

- Anti-kickback mechanisms

- An emergency stop system

These features reduce operational risks by up to 90%, especially important for high-speed, continuous cutting environments.

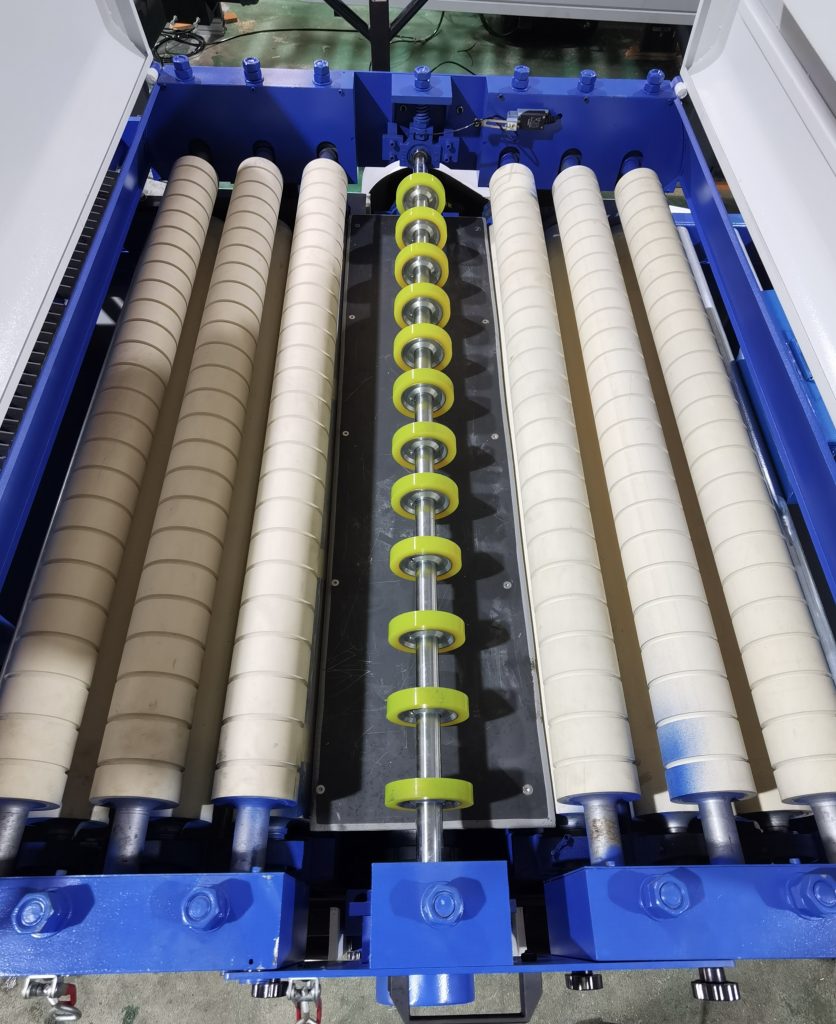

Military-Grade Efficiency

- High-torque main spindle motor

- Wear-resistant rubber feed rollers

- Max feed speed: 12 m/min

- Handles materials from 5mm to 90mm thick

The HD1300 delivers continuous 24-hour cutting power with minimal downtime and excellent adaptability to various board types.

Intelligent Energy Savings

- Inverter-controlled variable speed drive reduces energy use by 35%

- Smooth, no-loss start/stop mechanism

- High precise processing of the spacer to make it own a extra long lifespan

Technical Recommendations by Model

| Model | Recommended For |

|---|---|

| HD1300-X3L | Entry-level operations with moderate workloads and board thickness up to 30mm |

| HD1300-XD3L | Mid-tier plants needing more robust structure and higher thickness capacity |

| HD1300-XD4L | Heavy-duty users demanding maximum stability and long-hour, high-strength processing |

Application Fields

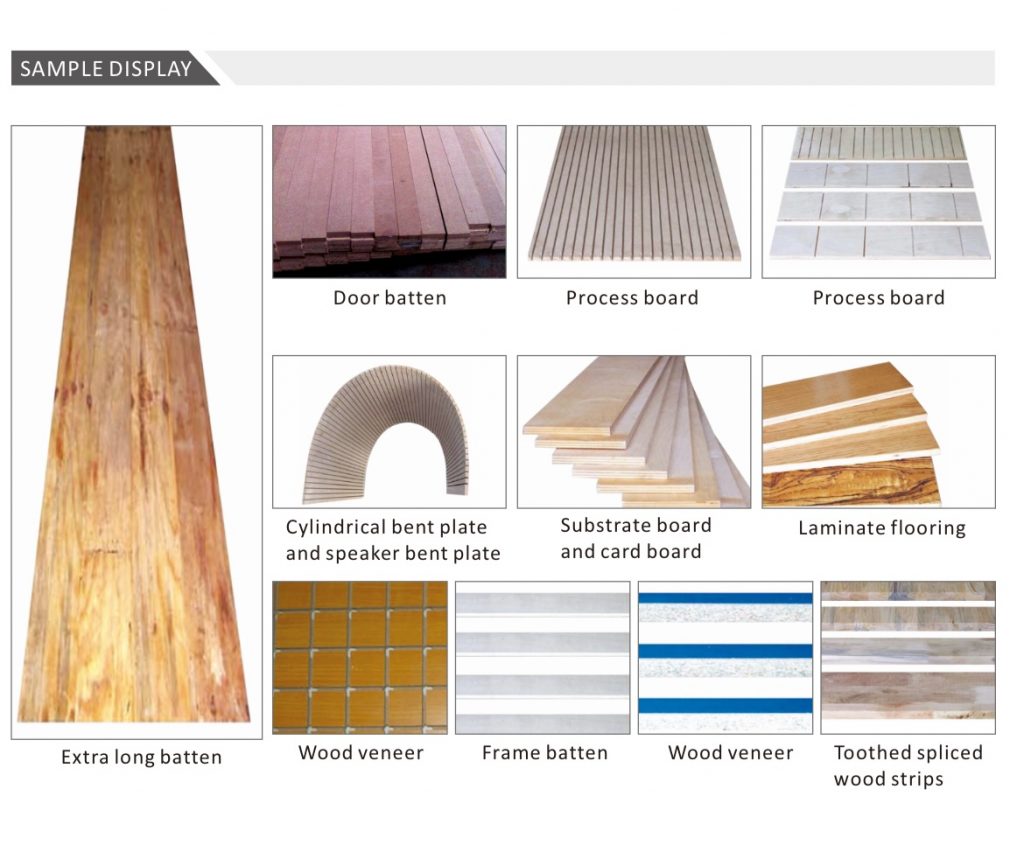

Furniture Manufacturing

Ideal for sizing and slitting standard panels in mass production of wardrobes, cabinets, and nightstands.

Construction Material Processing

Used for cutting plywood, laminated materials, and solid wood composite parts such as door cores, molding, and bed slats.

Logistics & Packaging

Boosts the precision and speed of pallet and crate component cutting, including gypsum boards, insulation panels, and calcium silicate boards.

Flooring & Eco Materials

Optimizes baseboard preparation for engineered flooring and acoustic panel fabrication.

Specialty Applications

Flexible enough for PVC, craft board, and other special material formats—ideal for manufacturers needing precision and versatility.

Value-Added Support Services

Full-Cycle Technical Assistance

From machine installation to after-sales troubleshooting, our support system is built to keep your production running with minimal interruptions.

Cost-Controlled Parts & Recycling

We offer low-cost parts, lifetime supply at factory prices, and used-part recycling programs to reduce your maintenance budget.

Documentation & Training

Every HD1300 is delivered with a bilingual user manual, visual guides, and access to a customer knowledge base for fast onboarding and self-service learning.

Conclusion

If you’re seeking to enhance wood processing throughput, improve material utilization, and strengthen operator safety, the HENGDA HD1300 Gang Rip Saw Machine offers a proven path forward. Trusted by manufacturers across flooring, furniture, and wood packaging sectors, it’s more than a machine—it’s a competitive edge.

Contact us today for a customized quote or technical consultation and discover how the HD1300 can revolutionize your production line.