Gang Rip Saws: The High‑Efficiency Tool That Keeps Wood Processing Moving

As automation, precision, and speed become critical in wood production, gang rip saws remain the go-to solution for high‑volume straight-line cutting. Gang rip saw machines outperform many machines in raw throughput and material yield. Let’s dive into why—and when—they’re the best choice for your production line.

Blade-Fixed, Board-Moving Mechanics

- Gang Rip Saw Machine —Multiple blades fixed on a single spindle; wood is fed through via conveyor. Ideal for converting wide boards into several narrow strips in one pass. But cannot stack panels for safety considerations.

- CNC Panel Saw —Board is clamped; the blade moves under CNC control along X–Y axes. It supports stacked cutting (2–4 boards) and handles complex shapes.

Precision & Repeatability

Gang Rip Saw Machine achieves typical width tolerances of ±0.2 mm and length straightness around ±0.5 mm over 2.4 m—perfect for flooring slats and door frames.

CNC Panel Saw often delivers tighter accuracy—±0.1 mm or better—especially suited to angled cuts, dados, or nesting.

Throughput of Gang Rip Saws: Speed Is King

When ripping boards into strips, gang rip saws operate at up to twice the throughput of CNC panel saws—and sometimes 3–4× faster—thanks to parallel blade cutting.

CNC systems, while flexible, are inherently slower at simple rip operations due to sequential head movement.

Material Yield & Waste Control

Gang Rip Saw uses standard strip configurations to keep waste under 5%, with yield up to 95%—excellent for production of uniform components.

CNC Panel Saw leverages nesting software to minimize offcuts for multi-shape layouts and small parts production.

Automation & Changeover Advantage

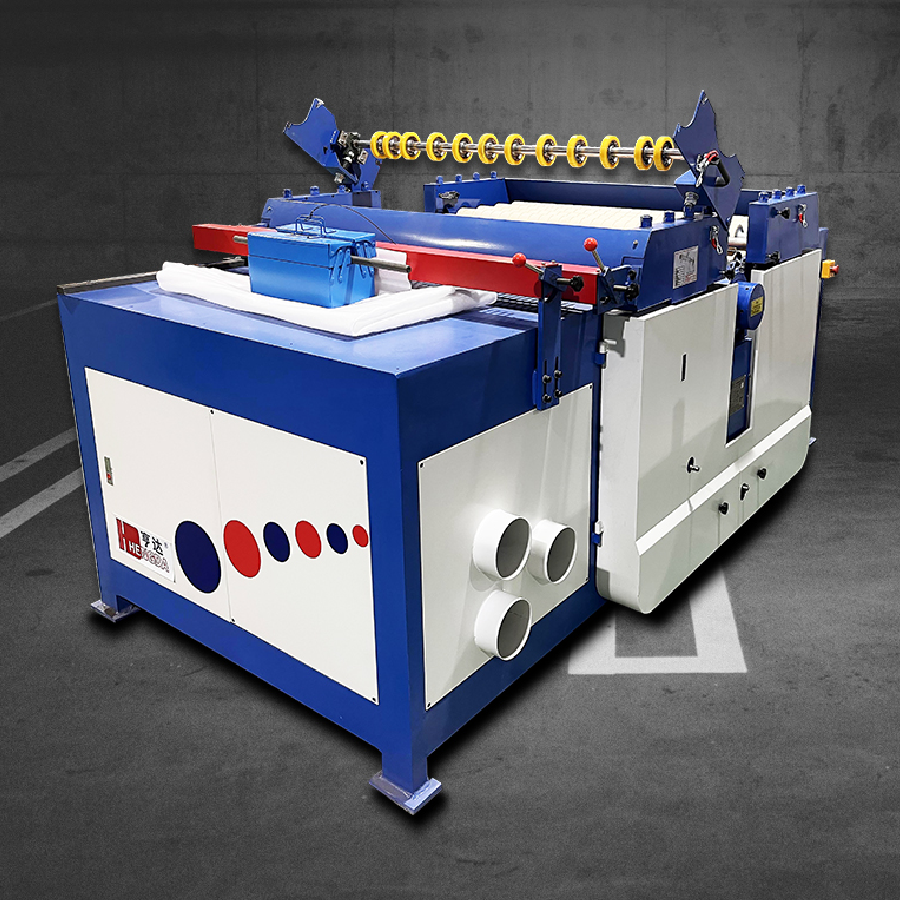

Gang Rip Systems can be integrated with auto‑feed conveyors and quick-swap spindle systems (like Hengda HDZ1300), cutting setup downtime dramatically.

CNC Panel Saws require no blade spacing changes—new patterns loaded via software. Best for varied geometry and small batch flexibility.

Cost, Space & ROI of Saw Machines

| Factor | Gang Rip Saw | CNC Panel Saw |

|---|---|---|

| Initial cost | Moderate | High |

| Footprint | Compact | Larger (gantry/table needed) |

| Labor required | One operator | Requires CNC programming |

| ROI timeline | 4–7 months (at high volumes) | Often 12–18 months for diverse jobs |

Optimal Usage Scenarios

Ideal for Gang Rip Saw:

Ideal for CNC Panel Saw:

- Custom furniture panels, cabinets, moldings, nesting jobs, and very tight geometric tolerances.

When cutting standard-width strips, a gang rip saw can deliver twice (or more) the throughput of a CNC panel saw—cutting multiple strips in one pass versus sequential cuts. This dramatically improves productivity and reduces labor strain.

Enhancing Gang Rip Saws Efficiency

Keep equipment clean: Daily cleaning prevents part rework and machine wear.

Optimize spindel layouts: Use fixed or moving blade spindles based on cut bills to improve yield and reduce downtime. Simulation or heuristics can help.

Have pre-set tooling ready: Quick-change bushings or spare spindle assemblies prevent delays in setup.

Conclusion

If you produce large volumes of standard-width or different-width wood strips, gang rip saws offer unmatched speed, yield, and return on investment. However, if your business demands customized parts, nested shapes, and batch diversity, CNC Panel Saws offer superior flexibility and precision. Many modern facilities combine both—using gang rip for high-volume ripping, and CNC for the finish or custom items.

Additionally, Hengda’s upgraded gang rip saw machines now feature a redesigned spindle and improved damping structure, significantly reducing operating noise. You’re not only getting efficiency and precision, but also a quieter working environment—making long shifts more comfortable and sustainable.