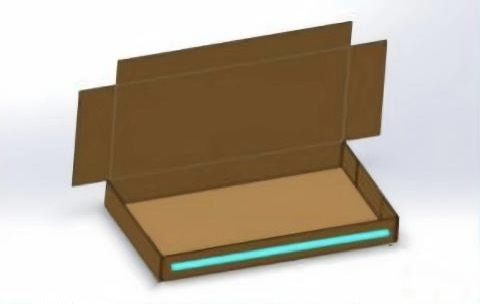

Flexible Glue Patterns With Hot Melt Glue Carton Sealing Machine For Smarter Packaging

In carton packaging, one size never fits all. Different products, carton sizes, and shipping conditions require different sealing strengths. While tape sealing machines can only apply a fixed strip of tape, a hot melt glue carton sealing machine provides multiple glue application options — such as dot spraying, line spraying, or double-line sealing. This flexibility helps manufacturers balance cost efficiency and seal strength, making hot melt glue sealing a smarter choice for modern packaging.

What Are Glue Patterns in Carton Sealing?

Glue patterns (or glue lines) refer to the way hot melt glue is applied to a carton’s flaps before they are pressed together. Common options include:

- Single Line Sealing – one glue strip applied along the flap edge.

- Double Line Sealing – two parallel glue strips for stronger bonding.

- Dot Spraying / Intermittent Gluing – glue applied in intervals, saving adhesive while maintaining sealing strength.

- Continuous Line Spraying – a full glue line for maximum sealing security.

This flexibility allows manufacturers to choose the best method for each packaging scenario.

Key Benefits of Flexible Glue Options

1. Cost Optimization

Not every carton requires a full glue line. With intermittent or dot spraying, glue consumption can be reduced by up to 30%.

Based on China market using hot melt glue carton machine, a single glue line costs only 0.033 RMB per meter, while a double glue line costs about 0.066 RMB per meter. By using single or intermittent lines for lighter cartons, manufacturers can achieve substantial savings.

2. Stronger Seals for Heavy or Large Cartons

For heavy products like furniture or appliances, high package boxes, double-line sealing provides extra bonding strength, ensuring cartons stay secure during long-distance shipping.

3. Greater Flexibility in One Machine

Instead of buying different sealing systems, one carton sealing machine with adjustable glue modes can handle all carton types — from lightweight e-commerce boxes to oversized furniture cartons. The glue modes can be adjusted automatically.

4. Improved Packaging Aesthetics

Hot melt glue leaves a clean, neat seam without tape overlaps or cuts. The ability to control glue patterns means cartons look professional while remaining secure.

Real-World Applications

- Furniture Industry – Large cabinets and wardrobes often require single glue lines, but office furniture often requires double glue lines for secure transport.

- E-Commerce Logistics – Small and medium boxes can be sealed with dot spraying, reducing adhesive costs.

- Appliance Packaging – Continuous glue lines provide added protection for fragile, high-value items.

Conclusion

A hot melt glue carton sealing machine isn’t just about automation — it’s about intelligent sealing. With flexible glue application modes like dot, line, single, or double spraying, businesses can reduce costs, improve sealing strength, and adapt to different packaging needs with a single machine.

Looking to optimize your packaging strategy? Explore how our carton sealing machines can bring flexibility and cost savings to your production line.