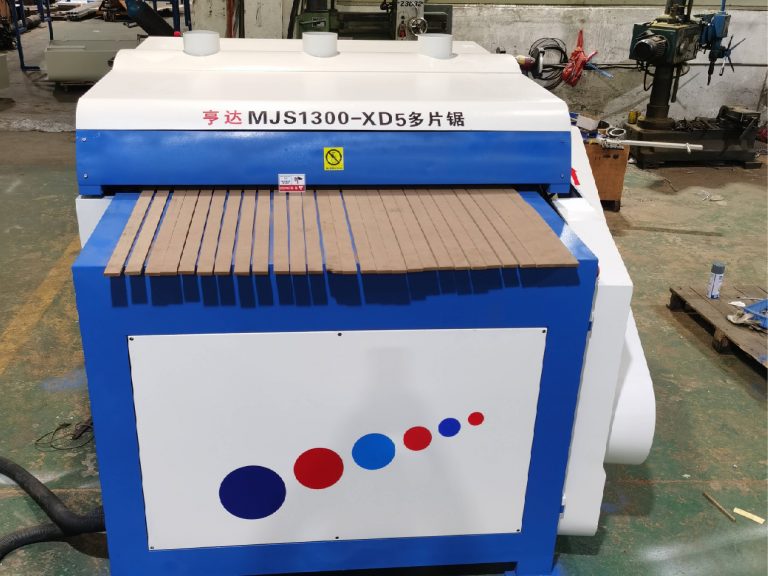

Feeding Mechanism of Multi Blade Saw Machine

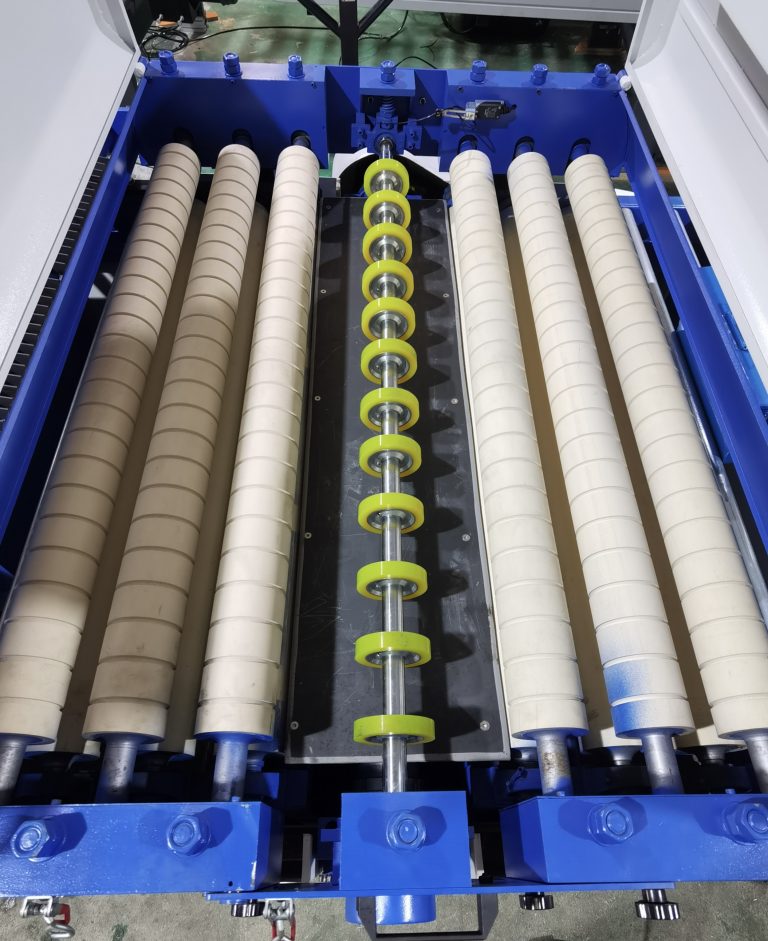

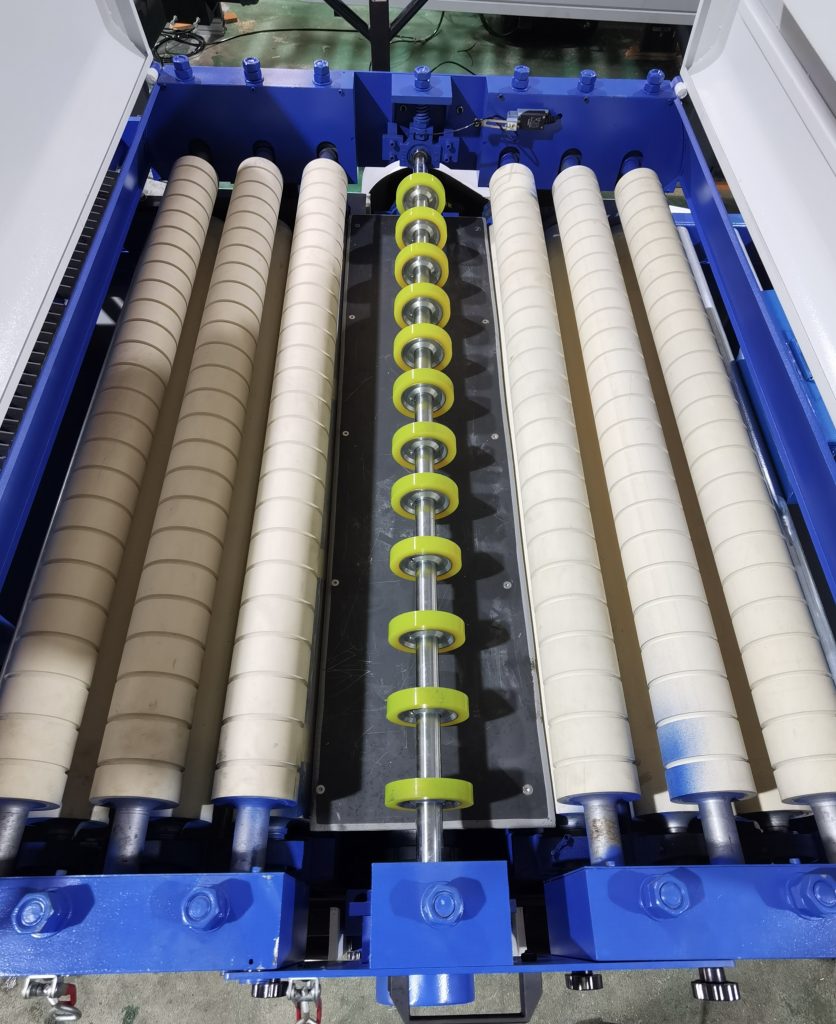

As we all know, when using the wood panel multi blade rip saw machine, the power of the motors and the sharpness of the blades are crucial in wood processing. However, there’s also a vital component–feeding mechanism. It ensures the operator safety and cutting precision to overall production efficiency. An unstable feed can lead to frustrating slippage, dangerous kickback, and costly rework. The upper rubber roller has a hardness of 70~80 and is made of butylene rubber with many grooves to increase friction for better conveying. The upper roller is a passive roller with no power, while the lower roller is a power roller.

We recognized these critical challenges. That’s why our multi-blade saws feature a meticulously engineered upper and lower rubber roller feed system—a design that different from most of the feeding mechanism of other machines. This article explores the Hengda feeding mechanism of wood panel multi blade rip saw machine.

Why the Feeding System Matters So Much

Even the most powerful saw blades and precise control systems can’t deliver optimal results if the material they’re cutting isn’t held firmly and advanced smoothly. A stable feeding system is the foundation for:

- Superior Cut Quality: Consistent material presentation to the blades ensures straighter, more accurate cuts.

- Enhanced Operator Safety: Preventing material movement like slippage or kickback drastically to ensure operator safety.

- Continuous Feeding: Reliable feeding minimizes stoppages and allows for continuous, high-speed processing.

- Machine Longevity: Reduced stress from erratic material movement extends the lifespan of critical components.

The Limits of Traditional Track Feeding

Many multi-blade saws on the market utilize a caterpillar track feed mechanism, these feeding mechanism often present inherent limitations:

- Increased Kickback Risk: Slippage is a primary cause of dangerous kickback, where the material is violently thrown back towards the operator, which would cause a huge accident.

- Uneven Pressure Distribution: Track pads might not apply uniform pressure across the entire surface of the board, leading to less secure gripping on wider materials.

- Wear and Tear: Chains can stretch, and the individual pads can wear unevenly over time, further compromising grip and overall feeding accuracy.

Precision and Power with Rubber Roller Feeding

Wood panel multi-blade saws leverage a superior upper and lower rubber roller feed system designed to overcome these drawbacks and redefine reliable material handling. The upper rubber roller has a hardness of 70~80 and is made of butylene rubber with many grooves to increase friction for better conveying. The upper roller is a passive roller with no power, while the lower roller is a power roller.

- Absolutely No Slippage, Stable Conveying: Our high-quality, wear-resistant rubber rollers apply a positive, consistent grip from both the top and bottom of the material. This powerful, symmetrical clamping action completely eliminates slippage, ensuring that even challenging wood surfaces or heavy boards are advanced smoothly and precisely, every time.

- Superior Stability for Large Boards, Zero Kickback Risk: This is where Hengda truly excels. The combined, synchronized force of our upper and lower rubber rollers forms an incredibly strong clamp on the board. This tight, unwavering pressure makes it impossible for the board to kickback or bounce, even when encountering knots or varying densities during high-speed cutting. This feature is paramount for both safety and maintaining flawless cutting accuracy, especially crucial when processing large, heavy, or long boards.

- Even Pressure Distribution: Unlike mechanisms that might apply pressure unevenly, our roller design ensures the clamping force is distributed uniformly across the entire width of the board. This prevents localized damage or compression of the material and contributes significantly to achieving perfectly straight and consistent rip cuts.

- Enhanced Safety: The inherent stability of our non-slip, anti-kickback roller system dramatically reduces the most common risks associated with multi-blade saw operation. This provides a significantly safer working environment for your operators.

- Consistent Cut Quality & Increased Productivity: With absolutely no slippage and uniform pressure, the material is presented to the saw blades with unparalleled stability. This translates directly into consistently accurate, straighter, and smoother cuts. Reliable, uninterrupted feeding also means fewer stoppages, leading to significantly higher continuous throughput and overall productivity.

The benefits of Hengda’s roller feed system are particularly evident in applications requiring maximum stability and safety, even when processing large, heavy, or long timber for construction or heavy furniture components, or cutting materials with inconsistent surface textures or moisture content.

Conclusion

The feeding mechanism of a multi-blade saw is not merely a means to an end; it is a core component that profoundly impacts safety, precision, and efficiency. While caterpillar track systems have their place, Hengda’s individual upper and lower rubber roller feed system offers a clear advantage. Its unparalleled ability to prevent slippage, eliminate kickback, and apply uniform pressure ensures stable conveying for even the largest boards.