Feed Rate vs. Blade Speed: Achieving the Perfect Balance in Multi Blade Saw Operations

Introduction

Achieving optimal performance and maximizing tool life in multi blade saw operations hinges on one critical factor: the perfect balance between feed rate and blade speed.

When calibrated correctly, these parameters ensure clean, accurate cuts, extend blade lifespan, and maintain operator safety. When misaligned, they can cause burning, blade damage, poor cut quality—or even serious safety hazards.

In this guide, we’ll break down what feed rate and blade speed are, how they interact, and how flooring and wood packaging manufacturers can optimize this relationship for maximum efficiency and safety.

What Are Feed Rate and Blade Speed?

Feed Rate

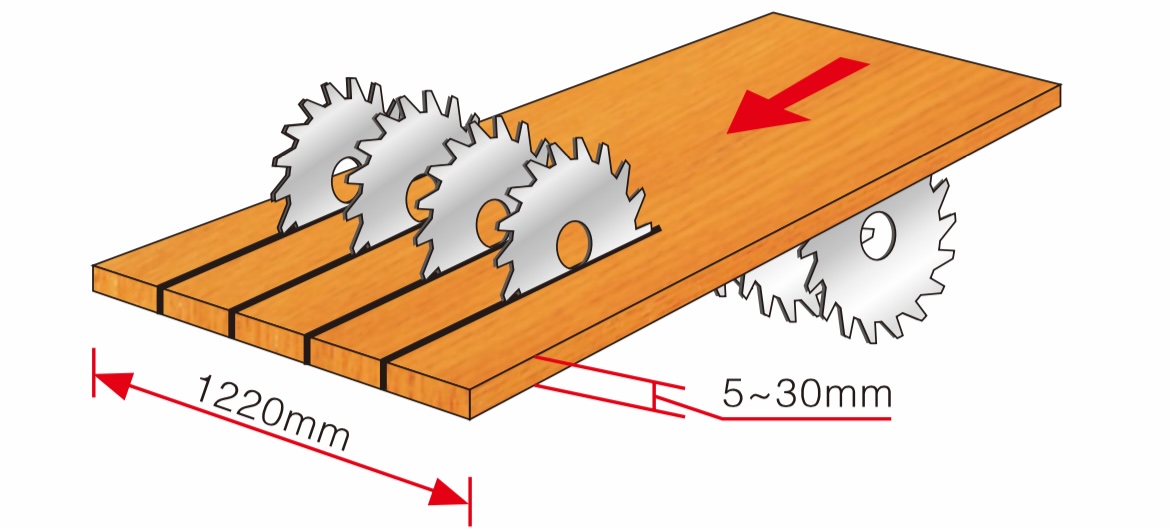

Feed rate refers to the speed at which wood is fed into the saw blades, typically measured in millimeter per minute (mm/min). It determines how quickly material moves through the cutting zone.

Factors that affect feed rate include:

- Type and hardness of the wood (e.g., softwood vs. hardwood)

- Thickness and width of the material

- Number of saw blades on the arbor

- Motor torque and power

- Desired cut finish and accuracy

Blade Speed

Blade speed is the rotational speed of the saw blade, often measured in revolutions per minute (RPM). It’s also influenced by the diameter of the blade: larger blades need to spin slower to maintain a safe and effective cutting speed at the tooth edge.

Key factors influencing blade speed:

- Blade diameter and number of teeth

- Motor power and gearing

- Type of cut (roughing vs. finishing)

The Interrelationship: Feed Rate × Blade Speed

The connection between feed rate and blade speed is not just mechanical—it’s fundamental to the concept of chip load.

What Is Chip Load?

Chip load is the amount of material removed by each tooth on the saw blade. It’s determined by dividing the feed rate by the number of teeth contacting the material at a given time.

Maintaining the right chip load is essential:

- Too small: causes friction, burning, and dulling

- Too large: stresses the blade, motor, and results in rough edges

When feed rate and blade speed are in balance, chip load stays in the optimal range—ensuring efficient material removal and clean, accurate cuts.

The Risks of Incorrect Settings

⚠️ Too Slow Feed Rate:

- Burn marks on wood surface

- Blade overheating and premature wear

- Lower productivity and higher energy consumption

⚠️ Too Fast Feed Rate:

- Tear-out, rough cuts, or blade deflection

- Excessive motor load, increasing failure risk

- Greater chance of kickback or operator injury

⚠️ Too Slow Blade Speed:

- Ineffective cutting

- Wood fibers crushed instead of sheared

- Excessive pressure required to move material through

⚠️ Too Fast Blade Speed:

- Risk of overcutting or blade instability

- Reduced chip evacuation

- Unnecessary energy use

Factors That Influence Ideal Settings

To find the best feed rate/blade speed combination, consider:

| Factor | Impact |

|---|---|

| Wood Type | Hardwoods need slower feed, higher blade speed; softwoods are more forgiving. |

| Moisture Content | Wet or resinous woods slow cutting and may require blade speed adjustments. |

| Material Thickness | Thicker stock generally requires slower feed rates for clean results. |

| Blade Configuration | More teeth = smoother cut but lower chip capacity. Choose based on application. |

| Motor Power | Higher torque allows for faster feed without sacrificing quality. |

| Number of Blades | More blades = more resistance. Requires careful tuning of feed system. |

Practical Tips to Find the Right Balance

- Follow Manufacturer Guidelines: Always begin with the saw and blade manufacturer’s recommendations.

- Start Slow and Tune Up: Begin with conservative feed rates, then gradually increase while monitoring cut quality and machine load.

- Watch the Chips: Properly sized chips should be uniform—not dusty, not oversized.

- Listen to the Machine: Changes in noise, vibration, or motor strain are signs of incorrect settings.

- Use Test Cuts: Before running full batches, test small samples and evaluate results.

Smart Sawing: Automation and Control

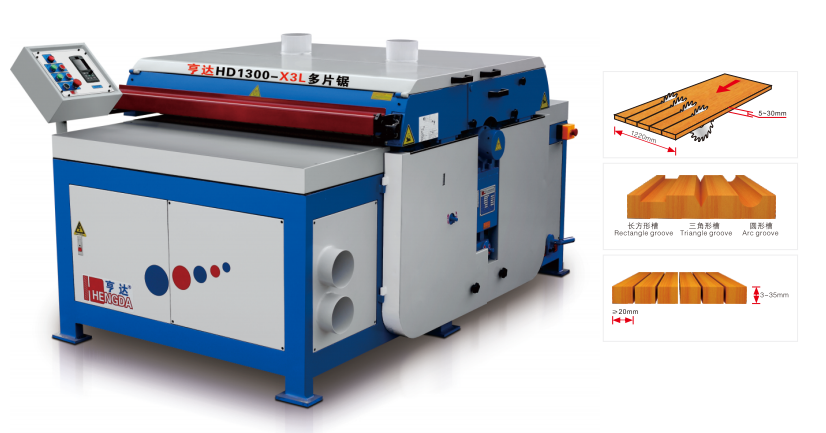

Modern gang rip saws are increasingly equipped with automation systems to monitor and control feed and blade speeds dynamically.

Advanced Features:

- Variable Frequency Drives (VFDs): Adjust feed motor speed based on wood density and load.

- PLC Systems: Save preset cutting programs for different materials and thicknesses.

- Sensors & Feedback Loops: Automatically detect resistance and adjust parameters in real time to protect the blades and motor.

These systems not only improve productivity but also ensure safe operation—even during 24/7 production.

Safety First: Why Getting This Right Matters

The right combination of feed rate and blade speed doesn’t just improve quality—it ensures safety.

- Incorrect settings increase the chance of kickback, blade damage, or material binding.

- Overloaded motors are prone to overheating or failure.

- Well-tuned systems are safer, more stable, and easier for operators to manage.

Modern machines often feature:

- Emergency stops

- Power cutoff on dust cover open

- Anti-rebound devices

Proper setup and maintenance remain essential—regardless of machine sophistication.

Conclusion

Balancing feed rate and blade speed in gang rip saw operations is part science, part skill—but fully critical. Get it right, and you unlock:

✅ Faster production

✅ Longer blade life

✅ Cleaner cuts

✅ Safer operations

Get it wrong, and you risk downtime, material waste, and safety incidents.

Want help optimizing your production line?

📩 Contact HENGDA for expert advice on gang rip saw configuration, or download our feed rate calculator guide to get started.