Electronic Beam Saw vs. Multi-Blade Rip Saw: Which is Right for Your Factory?

Choosing the right cutting machine is one of the most important strategic decisions for any woodworking factory. Different types of saws are designed for different production goals, and the wrong choice can lead to inefficiency, material waste, and unnecessary costs. Two of the most widely discussed machines in modern woodworking are the electronic beam saw and the multi-blade rip saw.

At first glance, both machines seem to solve the same problem—cutting wood into usable sizes. However, their technology, functions, and applications are completely different. This article explores the differences between the two, helping factory managers and production planners decide whether an electronic beam saw or a wood panel multi blade rip saw machine is the better investment for their operations.

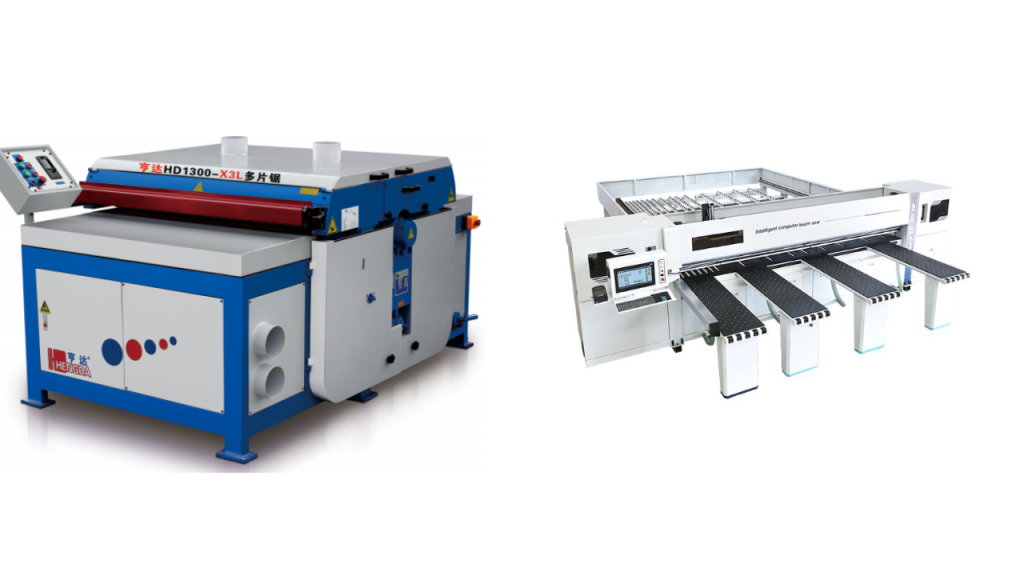

What Is an Electronic Beam Saw?

An electronic beam saw, also known as a CNC panel saw or computer panel saw, is a highly automated cutting machine designed for sheet materials like MDF, particle board, melamine, or plywood.

Key features include:

- Computerized control system: Operators simply input cutting dimensions, and the machine automatically executes precise cuts.

- Optimization software: The saw arranges cutting patterns digitally to reduce waste.

- Straight-line precision: Cuts large panels into smaller boards with exact accuracy.

- Automation options: Many models come with automatic feeding, stacking, and unloading systems for high-volume production.

Electronic beam saws are widely used in the furniture and cabinet industry, especially in factories focusing on customized panel furniture.

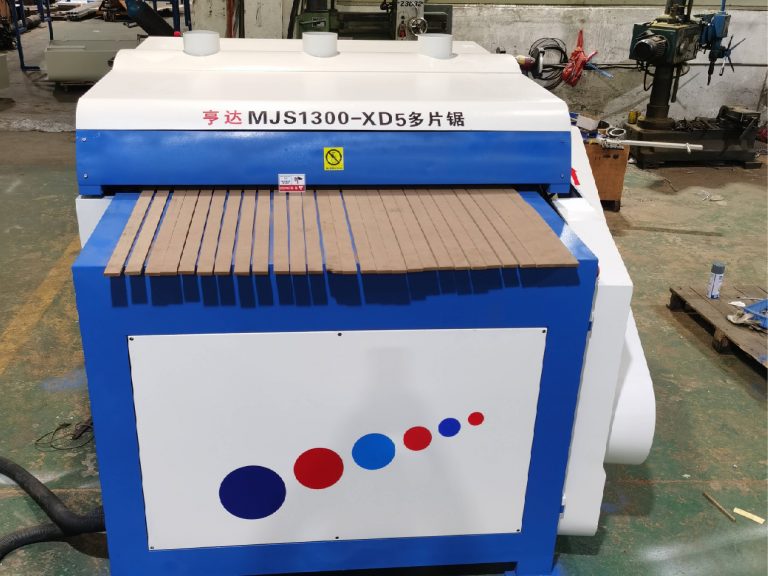

What Is a Multi-Blade Rip Saw?

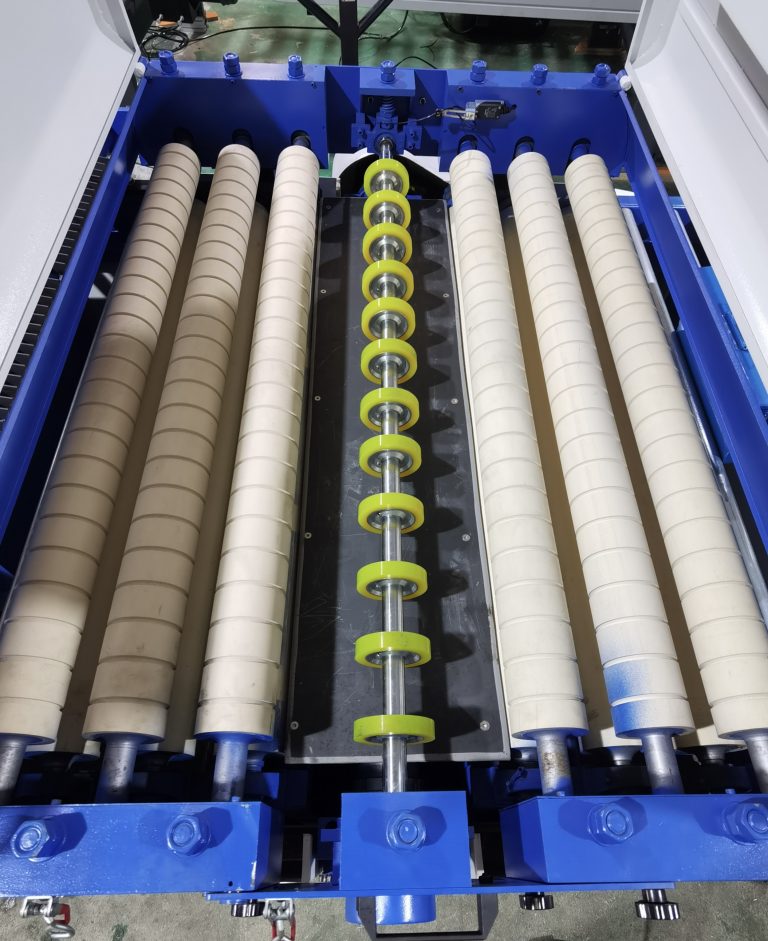

A multi-blade rip saw (sometimes referred to as a gang rip saw) is designed for solid wood processing. Instead of cutting one line at a time, it uses multiple blades mounted on a spindle, cutting a wood plank or panel into several strips in one pass.

Key advantages include:

- High throughput: Perfect for mass production where large volumes of identical strips are required.

- Consistency: Every pass delivers multiple identical pieces.

- Material yield: Thin kerfs and stable feeding systems reduce wood waste.

- Durability: Built for heavy-duty, continuous operation in flooring, pallet, or packaging factories.

A wood panel multi blade rip saw machine is ideal for industries like flooring, furniture frames, wooden crates, and packaging—anywhere consistent strip cutting is essential.

Speed and Productivity Comparison

When it comes to raw speed, the multi-blade rip saw clearly outperforms. Since it makes multiple cuts at once, it can process hundreds of boards per shift with minimal operator intervention. This is why it’s so popular in high-volume environments like flooring and pallet factories.

The electronic beam saw, however, prioritizes precision and flexibility over sheer speed. It is slower in terms of throughput but allows more varied and customizable cuts. For factories making wardrobes or kitchen cabinets with different panel sizes, the flexibility outweighs the speed disadvantage.

Verdict:

- Choose multi-blade rip saw for speed and high-volume cutting.

- Choose electronic beam saw for precision and customizable layouts.

Material Suitability

This is perhaps the clearest distinction:

- The electronic beam saw is specialized for engineered boards (MDF, plywood, particle board).

- The multi-blade rip saw is engineered for solid wood planks and all kinds of wood material.

Using the wrong machine on the wrong material not only reduces efficiency but may also damage the equipment. A wood panel multi blade rip saw machine will struggle with large MDF sheets, while an electronic beam saw is not designed for ripping long solid wood planks into strips.

Verdict: Match the machine to the material.

Precision and Cutting Quality

The electronic beam saw is unmatched in terms of dimensional precision. Guided by CNC software, it can deliver consistent cuts within tight tolerances, making it the best choice for high-end custom furniture.

The multi-blade rip saw, while extremely precise in repetitive strip cutting, is less flexible. Its design is optimized for repeatability, not custom one-off sizes. And with Hengda advanced multi-blade rip saw, the working noise of multi-blade rip saw is quite quiter than that of electronic beam saw.

Verdict:

- Electronic beam saw wins for precision variety.

- Multi-blade rip saw wins for repeat precision in mass production.

Cost and Return on Investment

Initial cost is another major difference:

- An electronic beam saw is often more expensive due to its CNC controls and automation features.

- A multi-blade rip saw is generally more affordable and offers quick ROI thanks to speed and material savings.

In the long run, ROI depends on your production type. A flooring factory cutting thousands of strips daily will recover its investment in a multi-blade rip saw much faster. A cabinet factory producing diverse customized panels will benefit more from the electronic beam saw despite its higher price.

Safety and Workforce Impact

Both machines prioritize modern safety, but in different ways:

- Multi-blade rip saws often use automatic feeding systems, keeping operators’ hands away from blades. And it’s equipped with an anti-bounce device and emergency stop.

- Electronic beam saws reduce manual handling of large panels, lowering the risk of strain or injury.

Both reduce reliance on manual labor, but the electronic beam saw typically requires operators with more technical knowledge to manage software and cutting optimization.

Conclusion

The choice between an electronic beam saw and a multi-blade rip saw ultimately depends on your factory’s focus:

- If you are in the solid wood industry (flooring, pallets, packaging), the wood panel multi blade rip saw machine will provide higher efficiency, less waste, and faster ROI.

- If you are in the panel furniture industry (wardrobes, cabinets, office furniture), the electronic beam saw will give you the precision, flexibility, and automation needed to handle diverse orders.

Both machines are indispensable in modern woodworking, but they serve different masters. By aligning your machine investment with your production goals, you ensure not just smoother operations but also stronger long-term competitiveness.