Ductile Iron For Multi-Blade Saw Spindle Bearing Housing

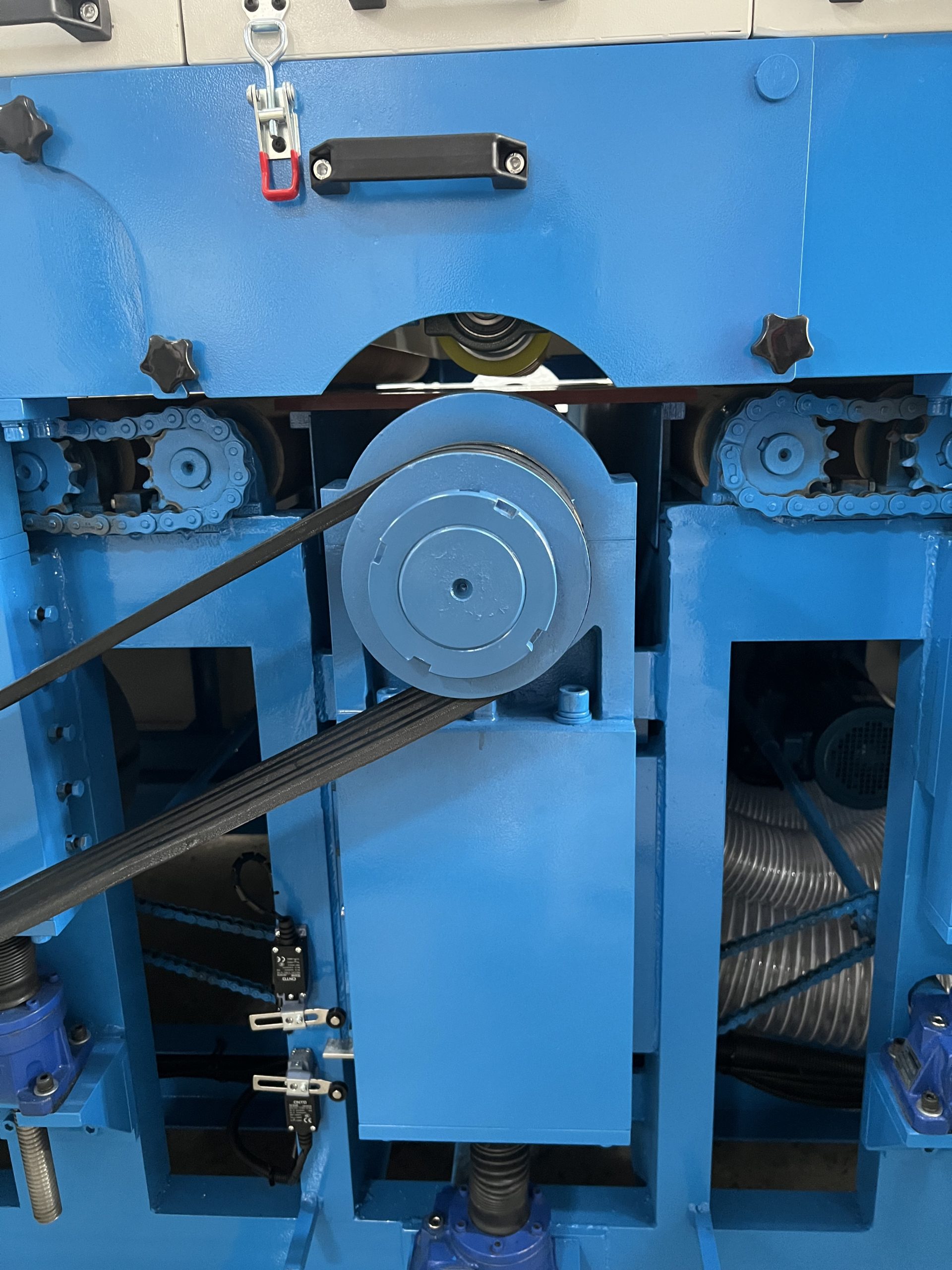

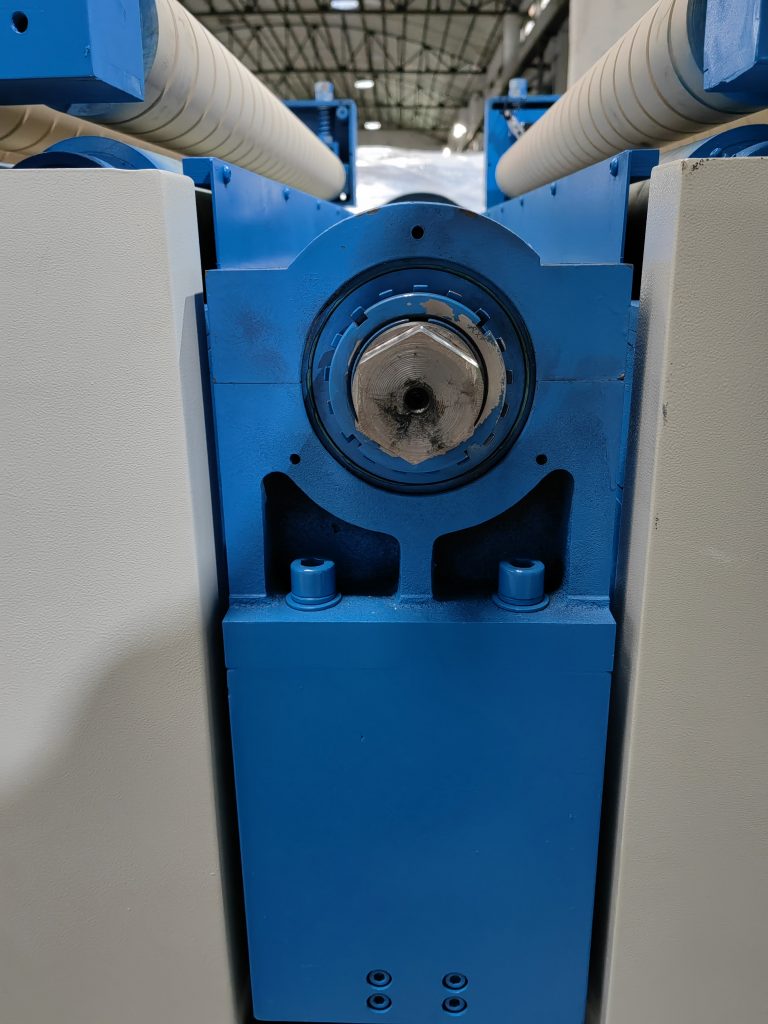

In many woodworking industrial factories, wood panel multi blade rip saw machine is very common. As a key piece of equipment in wood processing, the performance and lifespan of a multi-blade saw depend not only on motor power or blade sharpness. There is one component that withstands immense pressure and the challenges of high-speed rotation, directly influencing cutting precision and machine stability—the spindle bearing housing.

While many multi-blade saws on the market still use gray cast iron for their bearing housings, at Hengda, our pursuit of quality never stops. Across our entire range of multi-blade saws, we spare no expense in manufacturing spindle bearing housings from superior ductile cast iron. This is not merely a material upgrade—it is our solemn commitment to machine performance, durability, and customer value.

The Role of the Spindle Bearing Housing

The spindle bearing housing is the key component that supports and secures the spindle (the rotating shaft that holds the saw blades). It bears the following core functions and stresses:

- Support for High-Speed Rotation: The spindle rotates at thousands of revolutions per minute, requiring the bearing housing to provide stable support.

- Withstanding Powerful Cutting Forces: During wood cutting, the blades exert tremendous cutting forces, which are ultimately transferred to the spindle and bearing housing.

- Vibration and Heat Management: High-speed cutting inevitably generates vibration and heat, and the bearing housing must effectively absorb vibrations and dissipate heat quickly.

Any slight deformation or insufficient strength in the bearing housing will directly lead to spindle wobble, reduced cutting precision, shortened bearing life, and even equipment failure.

The Traditional Choice: Limitations of Gray Cast Iron Bearing Housings

Gray cast iron is widely used in machinery manufacturing due to its good casting properties and relatively low cost. However, for high-intensity, high-precision applications like multi-blade saws, gray cast iron bearing housings have inherent limitations:

- Insufficient Tensile Strength and Toughness: The microstructure of gray cast iron results in relatively low tensile strength and toughness. Under prolonged high-speed impact, high-frequency vibration, and heavy cutting forces, it is prone to micro-cracks and even brittle fractures.

- Inadequate Rigidity: Although cast iron has some rigidity, under continuous high-intensity work and temperature fluctuations, gray cast iron bearing housings may undergo slight but precision-affecting permanent deformation. This compromises spindle concentricity, leading to reduced cutting accuracy and unstable product quality.

- Poor Fatigue Resistance: Under long-term cyclic stress, gray cast iron is more susceptible to fatigue failure, shortening the lifespan of both the component and the entire machine.

Hengda’s Choice: The Advantages of Ductile Cast Iron

Unlike the flake graphite structure of gray cast iron, ductile cast iron undergoes a special nodularization process that distributes graphite in a spherical form. This microstructural transformation gives ductile cast iron far superior properties, making it the ideal choice for multi-blade saw spindle bearing housings:

- Exceptional Rigidity and Strength: Ductile cast iron has significantly higher tensile and yield strength than gray cast iron. This means HENGDA®’s spindle bearing housings experience almost no imperceptible deformation under high-speed rotation and heavy cutting forces. This extreme rigidity ensures stable spindle operation, eliminates wobble, and guarantees precise cutting accuracy.

- Outstanding Toughness and Impact Resistance: Ductile cast iron offers excellent toughness, resisting brittle fractures even under accidental impacts or heavy loads. This greatly enhances equipment safety and overall reliability, reducing the risk of sudden failures.

- Superior Fatigue Resistance: During operation, the bearing housing endures continuous cyclic stress. The exceptional fatigue resistance of ductile cast iron ensures long-term stable performance, significantly extending the lifespan of both the bearing housing and the entire saw.

- Efficient Heat Dissipation: Its excellent thermal conductivity allows ductile cast iron to quickly transfer heat generated by the spindle and bearings during high-speed operation, preventing overheating, protecting bearings, prolonging their life, and maintaining cutting stability.

- Zero Deformation, Long-Term Precision: Due to its outstanding stability and resistance to deformation, Hengda’s spindle bearing housings maintain their original dimensional accuracy and concentricity even after years of heavy use. This ensures your machine continues to deliver high-precision cuts while minimizing unnecessary maintenance and calibration.

Investing in Quality is Ensuring Your Products

Admittedly, ductile cast iron is more costly to manufacture than gray cast iron. However, we firmly believes that this additional investment delivers substantial long-term benefits for our customers:

- Extended Equipment Lifespan: A stronger, more resilient core component means more stable operation, lower failure rates, and a longer machine life.

- Consistent Cutting Precision: A deformation-resistant bearing housing ensures the machine maintains factory-level cutting accuracy even after years of use, significantly reducing waste and improving product quality.

- Lower Maintenance Costs: A stable bearing housing reduces wear and damage to bearings and other spindle components caused by deformation, cutting down on repair frequency and expenses.

- Higher Productivity and Safety: Stable machine operation means less downtime, higher production efficiency, and a safer working environment.

Conclusion

When choosing a multi-blade saw, don’t just focus on surface specifications and price. The true value of a machine and the future profitability of your factory often depend on the carefully selected, high-quality core components hidden inside.