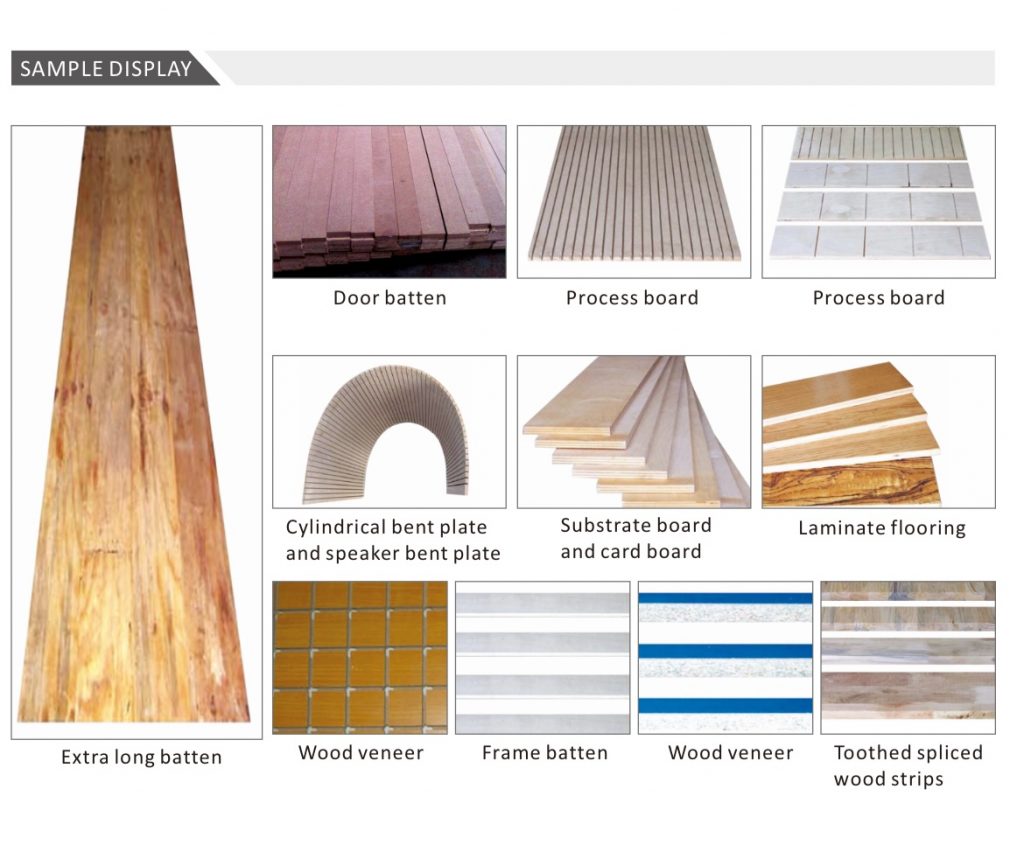

Differences Among Wood Plate Multi-Blade Rip Saws of Different Models: Choosing the Right Model for Your Production Needs

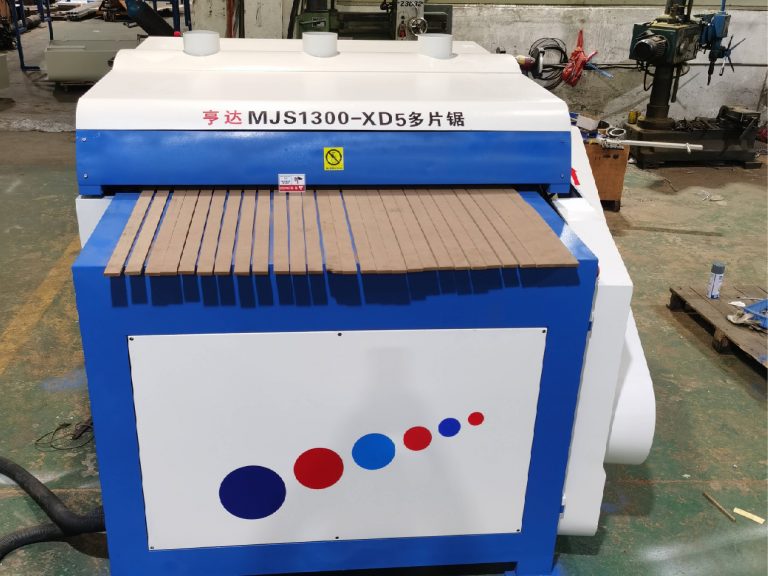

When it comes to woodworking, especially in industries that require high-speed, high-precision wood panel cutting, choosing the right equipment can make all the difference. The Hengda HD1300 series wood panel multi-blade rip saws are some of the most advanced machines available for processing wood panels. Whether you’re in furniture manufacturing, flooring production, or any other wood processing industry, selecting the right model is crucial for optimizing your production line. In this article, we will dive into the technical differences between four models in the HD1300 series: HD1300-X3L, HD1300-XD3L, HD1300-XD4L, and HD1300-XT2L.

Key Features of the HD1300 Series Panel Multi Blade Rip Saws

Each model in the HD1300 series is designed for a specific set of production requirements, ranging from small-scale operations to large-scale industrial use. The primary differences between these models lie in motor power, cutting capacity, number of feeding rollers, and working capabilities. These elements play a critical role in determining the performance, efficiency, and suitability for your business needs.

HD1300-X3L: Ideal for Thinner Board Cutting Production

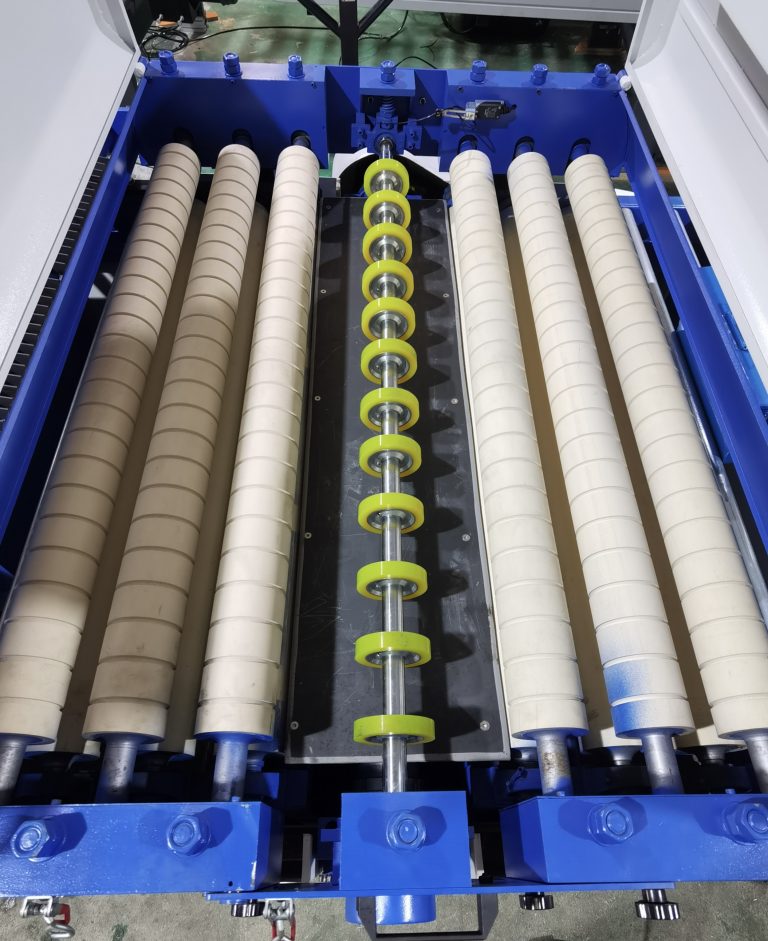

The HD1300-X3L is a basic model that is ideal for standard woodworking operations. It features 6 sets of feeding rollers (three in the front and three in the rear, based on the spindle), which provide stable feeding for moderate production volumes. With a maximum cutting thickness of 30mm, the HD1300-X3L is perfect for handling thinner panels.

Key Specifications:

- Motor Power: 11kW (with a maximum of 22kW)

- Feeding Speed: 0-12 m/min

- Feeding Rollers: 6 sets (3 front, 3 rear)

- Maximum Cutting Thickness: 30mm

The HD1300-X3L is perfect for businesses that need reliable, high-quality cuts with the need for thinner wood panels cutting production.

HD1300-XD3L: Weighted to Enhanced Stability

The HD1300-XD3L model takes things a step further with a 7-set feeding roller configuration (four in the front and three in the rear), allowing for even smoother feeding and greater stability. With a maximum cutting thickness of 45mm, the HD1300-XD3L can handle thicker materials compared to the HD1300-X3L. It also provides higher motor power to handle more demanding tasks.

Key Specifications:

- Motor Power: 18.5kW (with a maximum of 37kW)

- Feeding Speed: 0-12 m/min

- Feeding Rollers: 7 sets (4 front, 3 rear)

- Maximum Cutting Thickness: 45mm

The HD1300-XD3L is an excellent choice for operations that require stability, efficiency and cutting demands.

HD1300-XD4L: High Volume Cutting with Increased Feeding Capacity

- The HD1300-XD4L is designed for stable production for thicker boards, featuring 8 sets of feeding rollers (four in the front and four in the rear). This increased feeding capacity allows it to process large volumes of wood panels quickly and efficiently. It is capable of handling materials up to 60mm thick and is suited for large-scale operations that need high-speed cutting.

Key Specifications:

- Motor Power: 24.2kW (up to 48kW)

- Feeding Speed: 0-12 m/min

- Feeding Rollers: 8 sets (4 front, 4 rear)

- Maximum Cutting Thickness: 60mm

The HD1300-XD4L is best for large-scale woodworking businesses that need high efficiency and large cutting capacities.

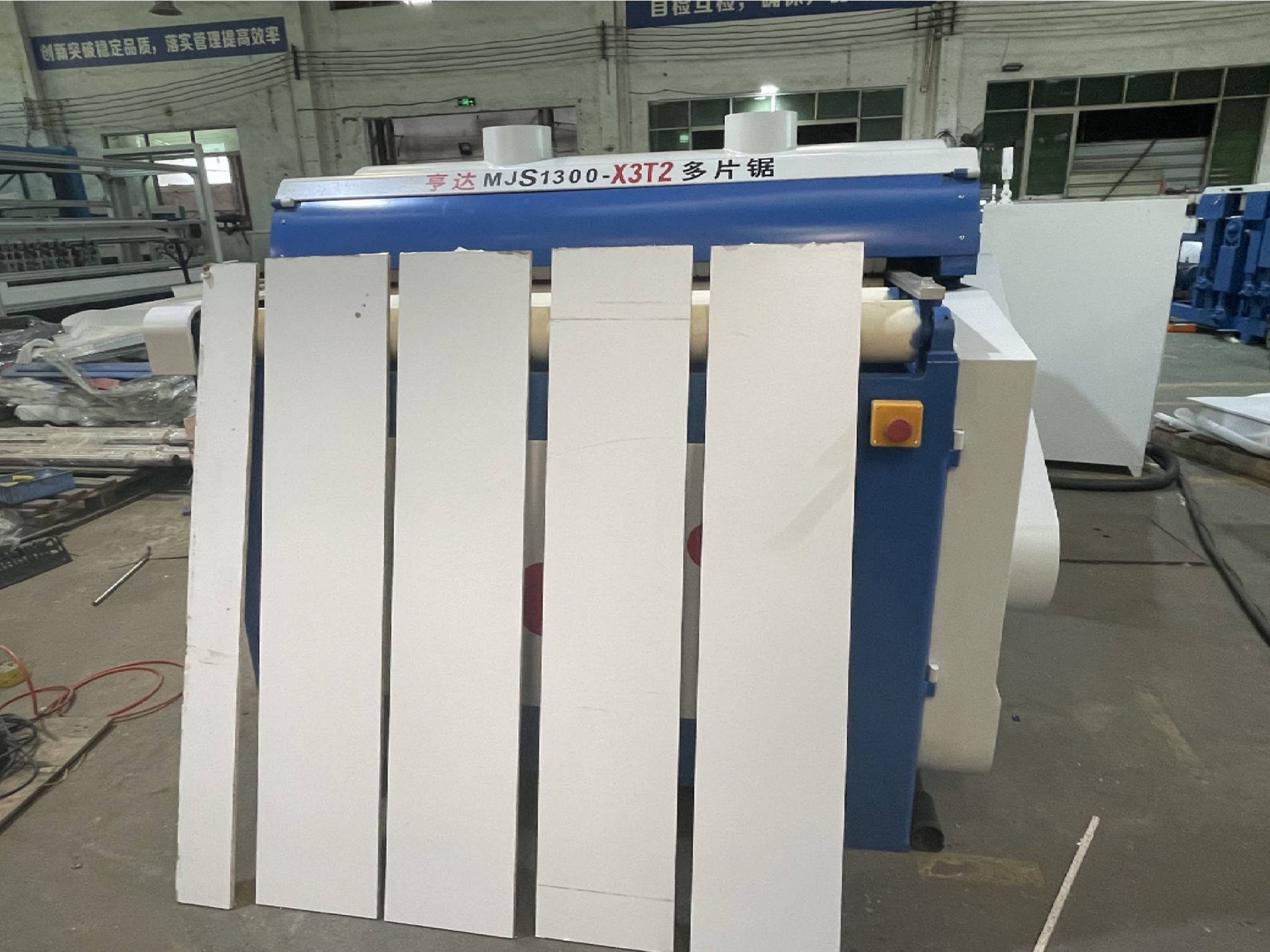

HD1300-XT2L: The Dual-Spindle Machine for Simultaneous Cutting and Slotting

The HD1300-XT2L is the most advanced model in the HD1300 series, offering a dual-spindle configuration. Unlike other models in the series, which feature lower-spindle systems (where the material passes over the blades from above), the HD1300-XT2L is equipped with both top and bottom spindles. This design allows for simultaneous cutting and slotting, making it ideal for two-in-one processing.

The HD1300-XT2L is perfect for businesses that require both cutting and slotting in one operation, saving time and improving overall efficiency. This model is suitable for high-throughput, fully automated production lines.

Key Specifications:

- Motor Power: 23.5kW (up to 47kW)

- Feeding Speed: 0-12 m/min

- Feeding Rollers: 6 sets (3 front, 3 rear) with dual spindles (top and bottom)

- Maximum Cutting Thickness: 30mm

The HD1300-XT2L is ideal for businesses aiming for high-speed, high-efficiency operations with integrated cutting and slotting capabilities.

Choose the Right HD1300 Model for Your Business

The HD1300 series is designed to meet the needs of various woodworking operations. Whether you’re working with standard 1220mm x 2440mm panels or require higher automation for large-scale production, the HD1300 series provides the ideal solution.

- HD1300-X3L is perfect for small to medium-scale production with basic cutting needs.

- HD1300-XD3L offers higher cutting capacity with high stability.

- HD1300-XD4L is designed for high-volume production with enhanced feeding capacity.

- HD1300-XT2L is the ultimate choice for fully automated operations, capable of simultaneous cutting and slotting.

Choosing the right machine depends on your production needs, and with the HD1300 series, you can achieve the precision and efficiency required for today’s woodworking industry.