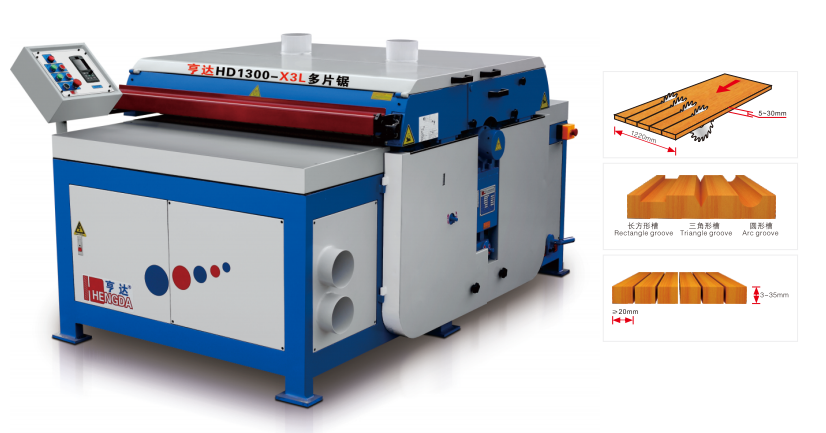

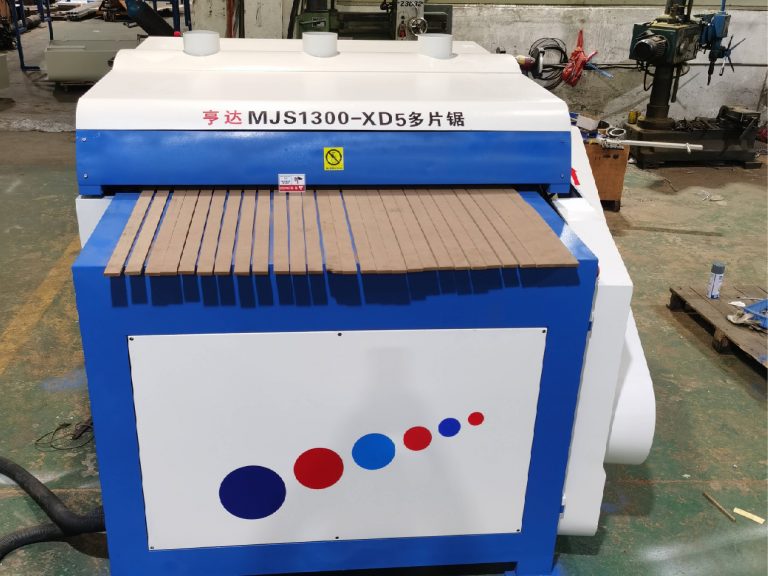

Depth Analysis of Wood Panel Multi-Blade Saw Machine 1300 Series

HENGDA 1300 Series of wood panel multi-blade saw machine offers both standard and custom-wide configurations to meet diverse processing needs. This article provides a detailed comparison of these models’ rubber-coated roller effective width and worktable dimensions, with special guidance for processing extra-wide boards on standard machines – empowering you to make the optimal choice for your production requirements.

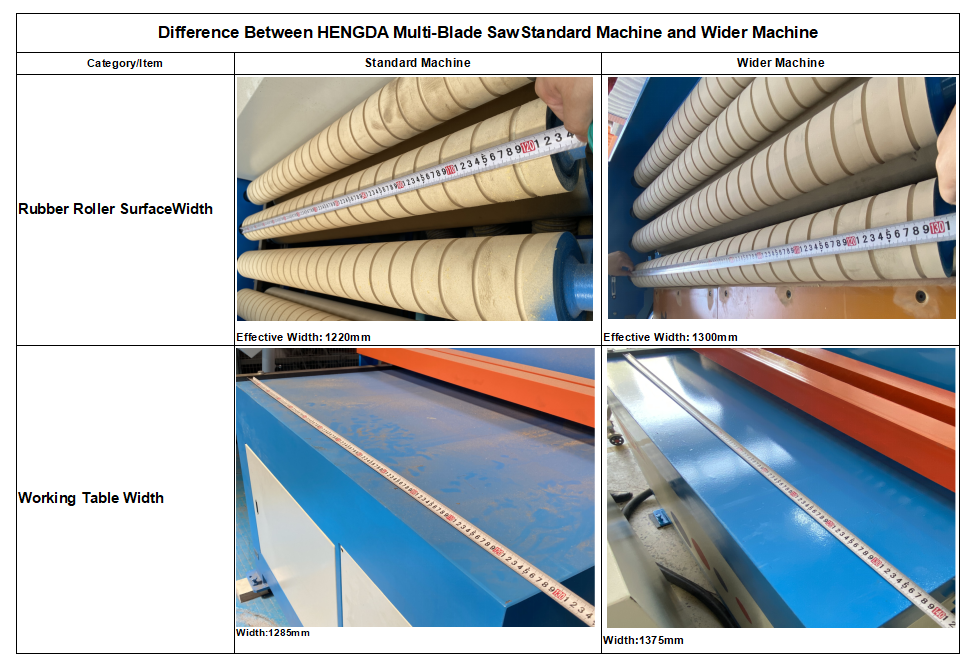

Core Parameter Analysis: Dimensional Differences Between Standard & Wide Models

To clearly demonstrate our 1300 Series’ capabilities, let’s examine its key dimensions:

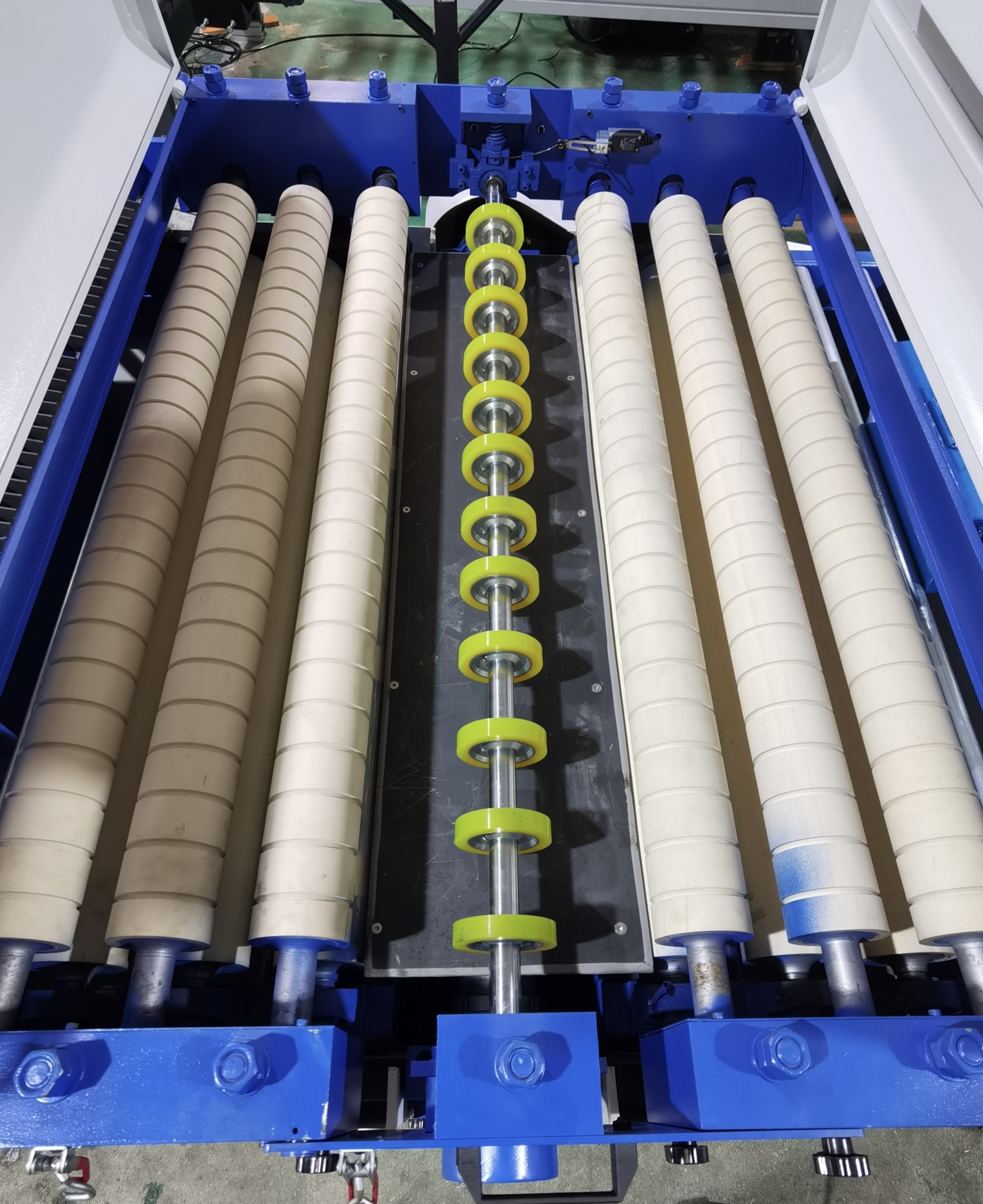

Rubber-Coated Roller Effective Width: The actual width for material gripping and stable feeding, determining maximum effective processing width.

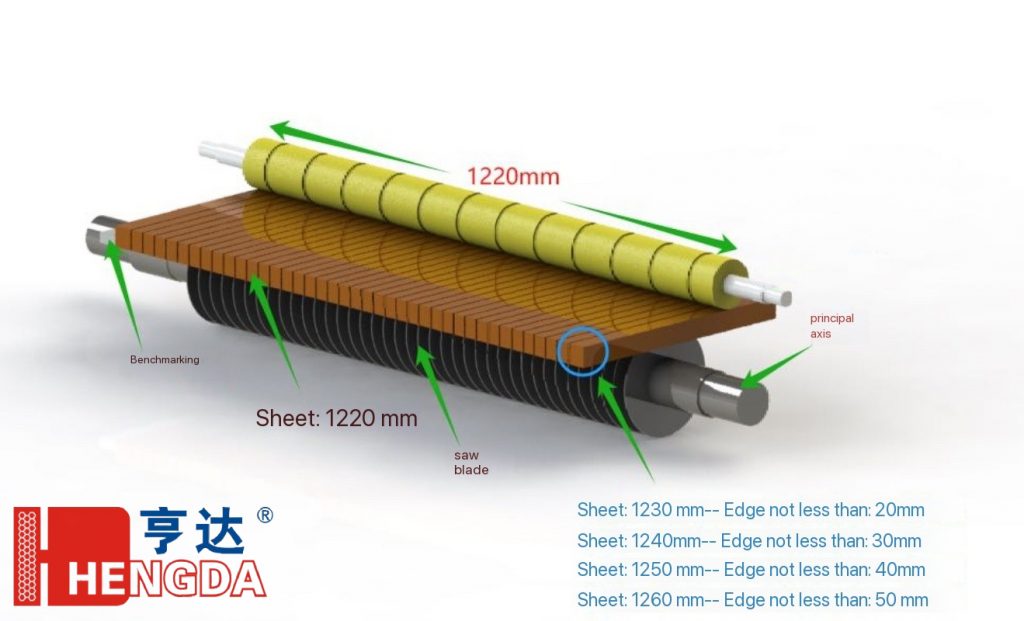

- Standard Model: 1220mm

- Wide Model: 1300mm

Worktable Width: The physical platform width for material support and guidance, defining maximum possible material width.

- Standard Model: 1285mm

- Wide Model: 1375mm

The wide configuration provides significantly greater capacity for broader materials.

Engineering Rationale: Why Worktable Width Exceeds Roller Width

This intentional design difference serves critical functions:

- Internal Mechanism Clearance: Accommodates feeding systems, blade assemblies, safety components and reference ruler.

- Smooth Material Flow: Prevents edge friction and jamming during entry/exit

- Operational Safety Margin: Provides necessary buffer space for handling

Configuration Selection Guide: Choosing Your Optimal Saw

Understanding these dimensions creates clear selection criteria:

For Materials ≤1220mm: Both standard and wide models provide full gripping capability. Standard configuration suffices.

For Materials >1220mm but ≤1285mm (Standard Model): Special conditions apply when exceeding the 1220mm roller width:

- 1230mm material: Minimum 20mm edge margin

- 1240mm material: Minimum 30mm edge margin

- 1250mm material: Minimum 40mm edge margin

- 1260mm material: Minimum 50mm edge margin

Processing Note: The extended portion beyond 1220mm remains unclamped, suitable for rough trimming operations but with reduced stability versus fully gripped processing.

For Materials >1220mm Requiring Premium Precision: The wide configuration (1300mm roller width) delivers:

- Full material clamping across entire width

- Maximum cutting stability

- Optimal precision for critical applications

Precision Engineering Philosophy: Custom Solutions

Our standard and wide configurations reflect our commitment to:

- Matching exact production requirements

- Ensuring long-term operational stability

- Maintaining cutting precision across all working conditions

When selecting your multi-blade saw, carefully consider:

- Typical material widths

- Precision requirements

- Edge margin tolerance

Choose HENGDA for professional, precise, and efficient wood processing solutions!