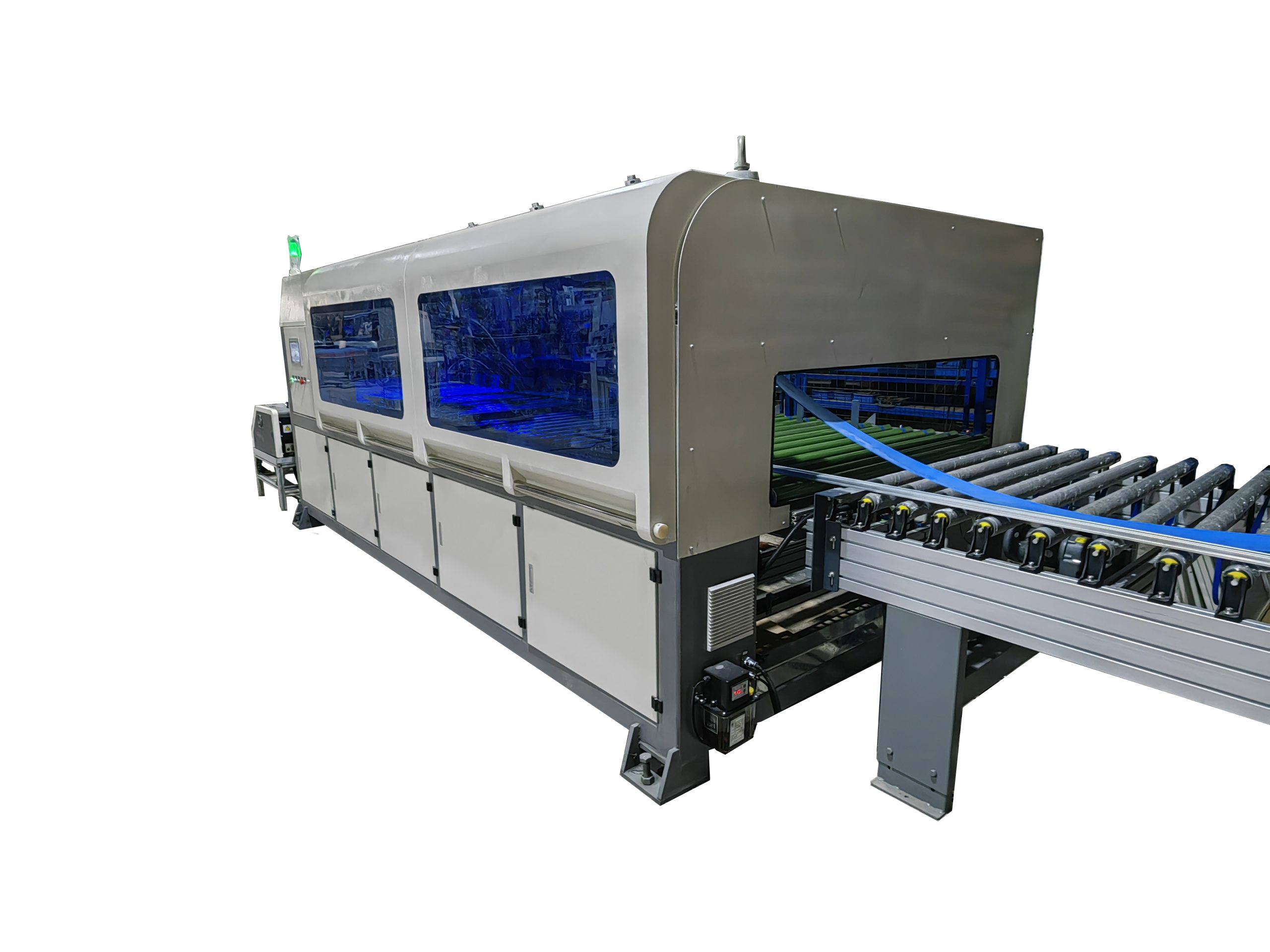

Cut Packaging Costs with a Hot Melt Glue Carton Sealing Machine

In today’s competitive manufacturing and logistics industry, packaging is more than just a finishing step — it’s a cost factor that directly impacts profitability. Traditional carton sealing methods, such as manual tape application, often result in high labor expenses, material waste, and inconsistent sealing quality. A hot melt glue carton sealing machine offers a smarter solution by reducing packaging costs while improving efficiency and product appearance. Hengda carton sealing machine is designed for side-sealed box(M410)only.

Why Packaging Costs Add Up Quickly

Packaging expenses don’t just come from boxes themselves; they also include:

- Labor costs for manual sealing.

- Tape or adhesive costs, often wasted due to overuse.

- Product damage and returns caused by weak or uneven sealing.

- Time lost during inefficient sealing operations.

Even small inefficiencies can accumulate into significant annual costs for furniture manufacturers, appliance suppliers, and logistics companies.

How a Hot Melt Glue Carton Sealing Machine Reduces Costs

1. Lower Material Consumption

Unlike tape sealing, hot melt glue is applied precisely where needed. Modern carton sealing machines allow dot spraying, line spraying, or intermittent gluing, ensuring no excess glue is wasted. This reduces adhesive costs by up to 30% compared with tape.

In fact, according to the user of Hengda carton sealing machine in China, the average cost of hot melt glue is only 0.033 RMB per meter for a single glue line and about 0.066 RMB per meter for double lines. Compared with carton tape, which is often applied in multiple layers, hot melt glue sealing delivers the same or better strength at a fraction of the material cost.

2. Reduced Labor Expenses

Manual sealing requires multiple operators for large cartons. A carton sealing machine automates the process, reducing the need for labor. Over time, the savings in wages and training can outweigh the initial investment.

3. Minimized Downtime and Rework

Uneven or weak sealing often leads to carton openings during storage or transportation. With hot melt glue sealing, cartons are securely bonded, preventing costly product returns and customer complaints.

4. Energy Efficiency

Hot melt glue machines heat and apply adhesive in a controlled way, minimizing power waste. The modern sealing machines feature servo control systems that optimize spraying speed and glue volume as well.

Real-World Example: Furniture Packaging

For furniture manufacturers, packaging often involves extra-large cartons (up to 2800mm long and 1200mm wide). Manual sealing with tape not only slows down the line but also increases tape usage. By switching to a hot melt glue carton sealing machine, a factory can:

- Seal up to 10 cartons per minute.

- Use less adhesive per carton compared to tape.

- Save thousands of dollars annually in labor and materials.

Long-Term Value Beyond Cost Cutting

Besides lowering packaging expenses, hot melt glue carton sealing machines also deliver:

- Stronger, cleaner seals for better brand presentation.

- Compatibility with automated packaging lines, enabling future factory upgrades.

- Flexibility to handle various carton sizes without excessive manual adjustments.

Conclusion

Switching to a hot melt glue carton sealing machine is not just about automation — it’s about cutting costs while enhancing packaging quality. By reducing material consumption, labor dependency, and rework, manufacturers can achieve significant long-term savings. For industries such as furniture, appliances, and e-commerce logistics, the move to hot melt glue sealing is a clear step toward leaner and smarter packaging operations.

Looking to lower your packaging expenses? Contact us today to learn how our carton sealing machines can transform your production line.