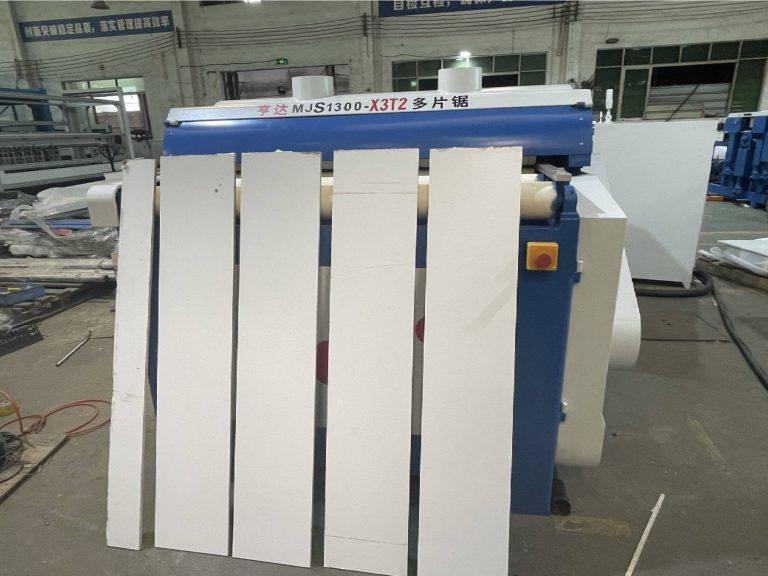

Category wood plate multi blade rip saw machine

Differences Among Wood Plate Multi-Blade Rip Saws of Different Models: Choosing the Right Model for Your Production Needs

When it comes to woodworking, especially in industries that require high-speed, high-precision wood panel cutting, choosing the right equipment can make all the difference. The Hengda HD1300 series wood panel multi-blade rip saws are some of the most advanced machines…

Top Applications of Wood Plate Multi Blade Rip Saw Machines in Furniture and Flooring Industries

Discover how wood plate multi blade rip saw machines transform furniture and flooring production with precision, speed, and material efficiency. The wood plate multi blade rip saw machine has become a vital tool in modern manufacturing, offering unparalleled efficiency and…