Category Corrugated Box Cutting Machines

1800mm Corrugated Cardboard Carton Cutting Machine(MAC-H4-18)

In the field of custom cabinetry packaging, many factories initially only required small carton-cutting packaging lines to meet daily carton production needs. Consequently, the traditional MAC-H4A carton cutting machine (with a maximum cardboard feed width of 1600mm) became the mainstream…

How to Maintain a Corrugated Cardboard Box Cutting Machine for Long-Term Efficiency

Investing in a corrugated cardboard box cutting machine is a smart move for factories looking to reduce packaging costs, improve flexibility, and produce cartons on demand. However, just like any industrial equipment, proper maintenance is essential to keep the machine…

Hengda Carton Cutting Machine: Enabling Flexible and Efficient Packaging Cutting

In the modern packaging industry, where product and order requirements grow increasingly diverse, the ability to efficiently and flexibly process different packaging materials through a single machine has become crucial for enhancing productivity and reducing costs. As one of the…

Hengda Carton Cutting Machine – The Intelligent Solution to Manual Packaging Challenges

In traditional packaging operations, reliance on manual carton cutting and forming presents significant pain points that directly impact production costs, product quality, and overall competitiveness. Hengda’s intelligent carton cutting machines provide a transformative solution to these persistent industry challenges. Critical…

Hengda: Pioneer in Carton Cutting Machine – Leading in Flexible Intelligent Packaging

Amid the surging wave of intelligent manufacturing, the packaging industry is undergoing unprecedented transformation. In this profound revolution, Hengda has distinguished itself through exceptional vision and relentless innovation, emerging as Guangdong’s first carton cutting machine R&D and manufacturer. This “first”…

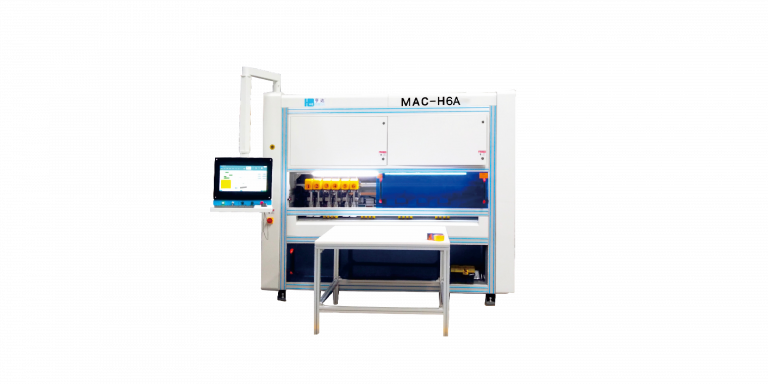

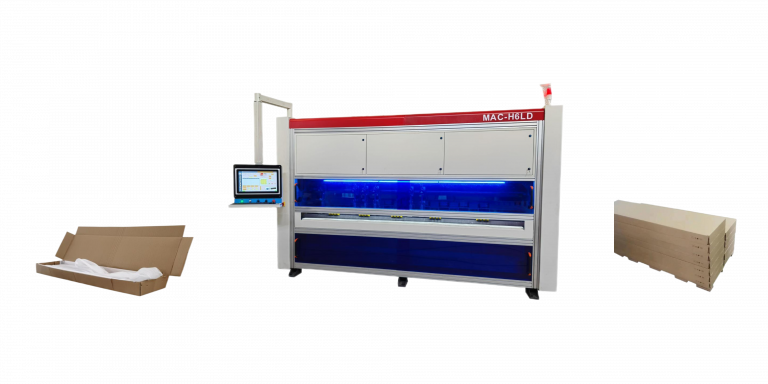

Hengda MAC-H6LD Intelligent Corrugated Carton Cutting Machine

In the realm of modern corrugated carton manufacturing, where cutting precision and production efficiency are paramount, the Hengda MAC-H6LD Intelligent Corrugated Carton Cutting Machine sets a new industry benchmark with its groundbreaking all-servo drive architecture. More than just a cutting…

Intelligent Carton Cutting Machine: how to achieve “zero” waste precision cutting?

In the packaging industry, where efficiency and cost control are increasingly prioritized, material waste in carton cutting poses a significant challenge for businesses. Traditional cutting methods not only lead to material wastage but are also often accompanied by issues such…