Boost Efficiency with HENGDA Automatic Longitudinal Transverse Multi Blade Saw Production Line

HENGDA®’s HD1325L automatic longitudinal transverse multi blade saw production line sets a new standard for high-throughput panel processing. Designed for flooring, laminated board, and furniture panel production, the HD1325L combines a continuous multi-blade rip saw and crosscut station into one infeed production line. Its through-feed design with multiple circular saws keeps material moving non-stop, delivering a “continuous flow of material” for maximum output. An industrial PLC synchronizes the feed rollers and saw spindles, making operation smooth, efficient and labor-saving. In practice, a worker simply loads large panels onto the worktable and push to the saw; the PLC then feeds each board through the longitudinal rip blades and transverse cut unit without stopping. The result is fast, automated cutting of long strips and cross‐cut pieces in one seamless workflow.

Streamlined Continuous Workflow

In production, the HD1325L’s automated workflow dramatically cuts cycle time. Boards are gripped by wear-resistant rubber feed rollers and pulled steadily into the saw train. The workflow is programmed to slice panels longitudinally (ripping them into strips) and also perform precise transverse crosscuts, all in one line. Variable-frequency drives adjust the feed speed from 0 to 12 m/min (as needed for different working demands). As one board exits, the next is already clamped and fed, realizing true “ceaseless continuous feeding”. HENGDA’s design often uses multiple blades on the arbor (for example, three saw blades in a row) to cut several strips simultaneously. By keeping panels moving from loading to finished strips without interruption, the HD1325L minimizes idle time and maximizes throughput

Automation & Safety Innovations

HENGDA automation means huge labor savings. With PLC-driven conveyors and adjustable feeding rollers, one operator can run the entire HD1325L line, compared to multiple workers needed on older machines. The PLC control is simple and reliable: operators set parameters once, and the saw automatically feeds and cuts panels at the set cycle, “time-saving and labor-saving” in operation. Continuous infeed eliminates manual lifting or pushing of boards between saws. At the same time, safety is engineered in. The HD1325L uses active/passive anti-kickback (anti-bounce) devices to prevent workpiece rebound. If a guard or dust cover is opened, an interlock immediately powers down the machine. In short, automated loading and sawing significantly reduce the need for workers at each saw, while advanced guards and auto-shutdown features keep the process safe without slowing production.

Ideal for Large-Scale Panel Applications

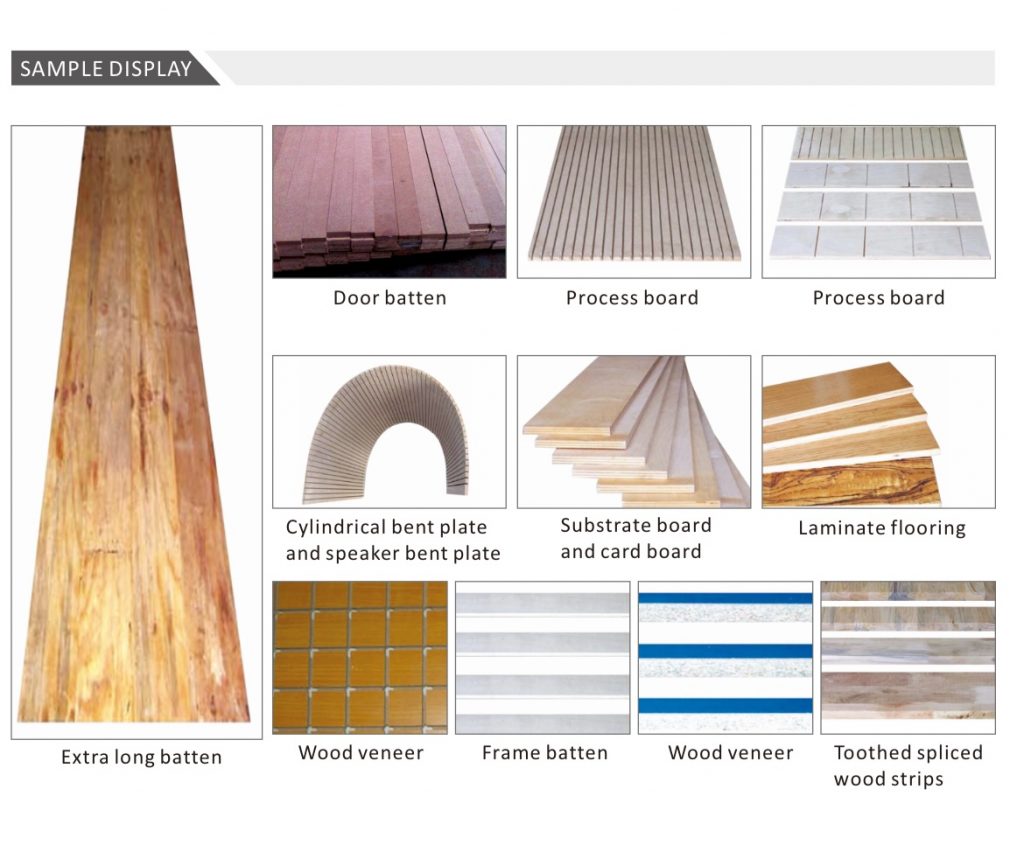

This production line is tailored for large, hard-working shops. Its wide processing capacity — up to 2600 mm panel width — means even giant laminate boards or hardwood flooring planks can be cut. Typical use cases include engineered wood flooring (where long strips are ripped from sheet stock), laminated furniture panels, doors, and other broad furniture components. Thanks to its “ceaseless continuous feeding,” the HD1325L is perfect for running long production batches of panel furniture, flooring and door blanks. Adjusting the feed speed or blade spacing is straightforward, so manufacturers can switch between different board sizes or thicknesses (5–35 mm is typical) without downtime. In practice, factories report that this kind of automated multi-blade saw line dramatically increases output of flooring panels or cabinet sides, while freeing labor for other tasks.

Technical Highlights

- Automated Feeding System: Conveyor feed rollers pull panels steadily into the saw units. Variable-frequency drives allow infinitely adjustable feed speed from 0–12 m/min, ensuring stable, continuous operation.

- Wide Cutting Capacity: Handles panel widths up to 2600 mm and thicknesses around 5–35 mm, accommodating large workpieces used in flooring, wall panels or furniture.

- PLC Control: An industrial PLC coordinates feeds and saws, enabling one-touch setup and consistent, repeatable cutting. This “time-saving, labor-saving, efficient” automation ensures high uptime.

- Multi-Blade Arbor: The saw arbor can hold several circular blades for rip cuts, allowing multiple strips to be cut at once. Secondary saw units perform crosscuts, so panels are cut to length and width in one pass.

- Safety Features: Top/bottom anti-kickback (anti-bounce) fingers and patented rebound protectors prevent material from kicking back during cutting. A safety interlock cuts power immediately if any cover is opened.

- Heavy-Duty Construction: Rugged welded frame, alloy feed tables and durable rollers minimize vibration and wear. The result is precise, stable cutting over long production runs

Contact HENGDA for Tailored Solutions

For international manufacturers seeking to upgrade their panel production, the HD1325L offers a turnkey solution. HENGDA® can customize the longitudinal-transverse multi-blade saw line to your facility’s needs — from feed length and blade count to integration with material handling. Boost your efficiency, cut labor costs and raise throughput with this automated production line. Contact HENGDA® today to discuss your requirements and get a tailored quote. Elevate your output with HENGDA’s expertise in high-capacity panel cutting.