Hengda Carton Cutting Machine – The Intelligent Solution to Manual Packaging Challenges

In traditional packaging operations, reliance on manual carton cutting and forming presents significant pain points that directly impact production costs, product quality, and overall competitiveness. Hengda’s intelligent carton cutting machines provide a transformative solution to these persistent industry challenges. Critical…

Hengda: Pioneer in Carton Cutting Machine – Leading in Flexible Intelligent Packaging

Amid the surging wave of intelligent manufacturing, the packaging industry is undergoing unprecedented transformation. In this profound revolution, Hengda has distinguished itself through exceptional vision and relentless innovation, emerging as Guangdong’s first carton cutting machine R&D and manufacturer. This “first”…

Hengda Intelligent Packaging Line: H4A Dual-Workstation With Scanning System

In the flexible production of custom cabinetry and custom home furnishing industries, where multi-specification, small-batch orders present challenges, intelligent and precise packaging solutions become crucial. Hengda presents the H4A Dual-Wokstation Carton Packaging Line With Scanning System – a highly integrated,…

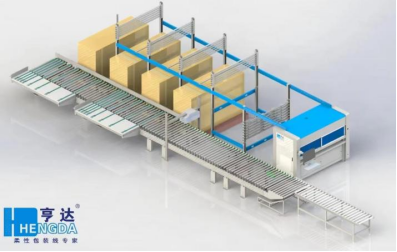

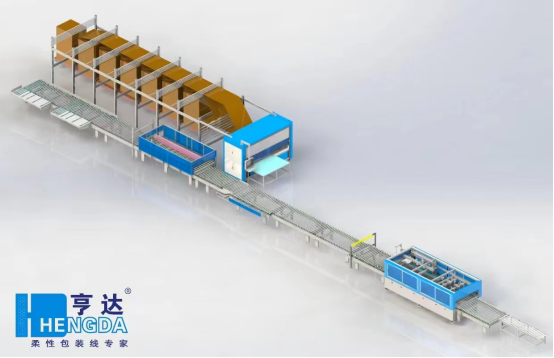

Hengda Intelligent Packaging Line: Customized Integration Solutions

In the era of smart manufacturing, flexibility and precision are key competitive advantages. Hengda, a leader in intelligent packaging solutions, understands the diverse needs of factories with different production models and scales. We offer customized packaging line integration solutions and…

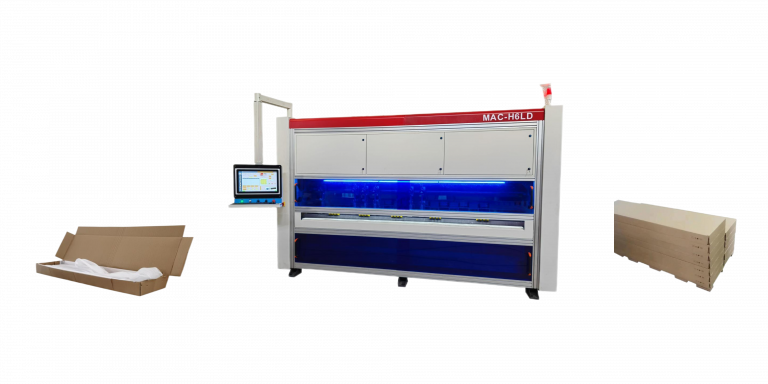

Hengda Intelligent Packaging Solution: H6LD Dual-workstation Whole Packaging Line

In the packaging processes of industries such as kitchen cabinetry and custom home furnishings, efficiency, precision, and standardization are core competitive advantages. Hengda, a leader in flexible packaging lines, proudly presents the H6LD Dual-workstation Measuring Station Whole Packaging Line Solution.…

Carton Sealing Machine – High-speed Continuous Sealing

In automated packaging production lines, the efficiency and quality of carton sealing directly impact product presentation and logistics performance. Hengda’s FXZB-R2812 linear carton sealing machine is specifically designed to automate this critical process. By replacing manual sealing operations with its…

Hengda Intelligent Packaging Line: FXZB-R2812 Linear Carton Sealing Machine

In automated packaging production lines, the efficiency and quality of carton sealing directly impact product presentation and logistics performance. Hengda’s FXZB-R2812 linear Carton Sealing Machine is designed to automate this critical process. By replacing manual sealing with its high-efficiency continuous…

Hengda Intelligent Packaging Line: MP-ATFX Automatic Box Sealing Machine

At the final stage of the intelligent packaging line, the box sealing process is crucial for ensuring product safety and packaging aesthetics. As a key component of Hengda’s intelligent packaging solutions, the MP-ATFX automatic box sealing machine delivers fast, secure,…

Hengda Intelligent Packaging Line With Seamless Dimensional Data Flow

In modern manufacturing, where extreme efficiency and perfect quality are pursued, every step of an intelligent packaging line must be tightly connected to achieve true automation. In Hengda’s intelligent packaging solutions, the measurement stations and intelligent corrugated carton cutting machines…

Hengda Intelligent Packaging Line: Precision Size Measurement Station

In highly automated packaging production lines, accurate dimensional measurement is the critical first step to ensure smooth subsequent processes like cutting, folding, and sealing, ultimately guaranteeing final packaging quality. Hengda’s intelligent packaging line features advanced size measurement station that provides…