Maximize Productivity with HENGDA® Automatic Wood Panel Multi Blade Saw Production Line

In today’s competitive woodworking industry, automation is key to staying ahead. HENGDA®’s automatic wood panel multi blade saw production line leverages cutting-edge automation to streamline panel cutting for doors, furniture, and flooring manufacturers. By integrating fully automated loading/unloading systems, high-speed…

Improving Wood Cutting Efficiency: Why the Wood Panel Multi Saw Machine is the Best Choice

In the wood processing industry, cutting efficiency plays a critical role in determining overall productivity. With increasing demands for high-quality wood products, manufacturers face the challenge of boosting production speed, reducing waste, and maintaining cutting precision. This is where the…

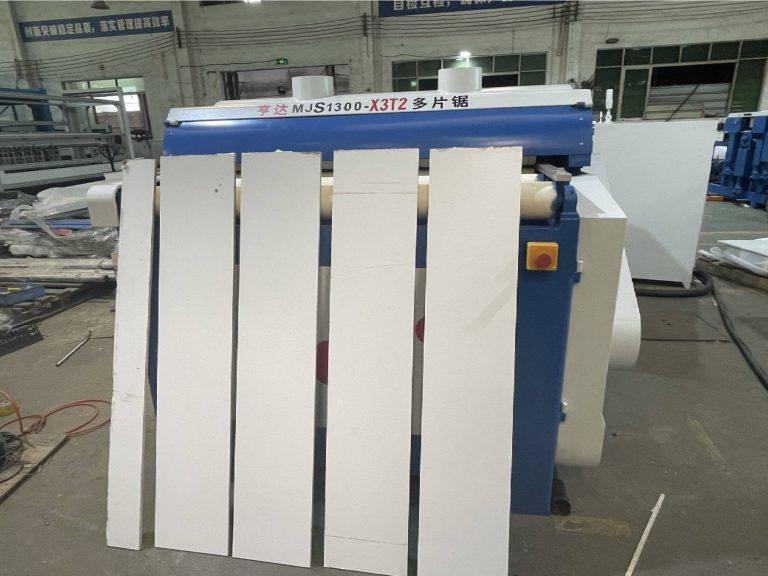

Differences Among Wood Plate Multi-Blade Rip Saws of Different Models: Choosing the Right Model for Your Production Needs

When it comes to woodworking, especially in industries that require high-speed, high-precision wood panel cutting, choosing the right equipment can make all the difference. The Hengda HD1300 series wood panel multi-blade rip saws are some of the most advanced machines…

Top Applications of Wood Plate Multi Blade Rip Saw Machines in Furniture and Flooring Industries

Discover how wood plate multi blade rip saw machines transform furniture and flooring production with precision, speed, and material efficiency. The wood plate multi blade rip saw machine has become a vital tool in modern manufacturing, offering unparalleled efficiency and…

A Bathroom Cabinetry Packaging Machine for Modern Production Lines

Explore a bathroom cabinetry packaging system designed for factories with 10–20k ㎡ monthly capacity—featuring light curtain measurement and see how it play a vital role in bathroom vanities factory. Precision and Flexibility in Bathroom Cabinetry Packaging As product variation increases…