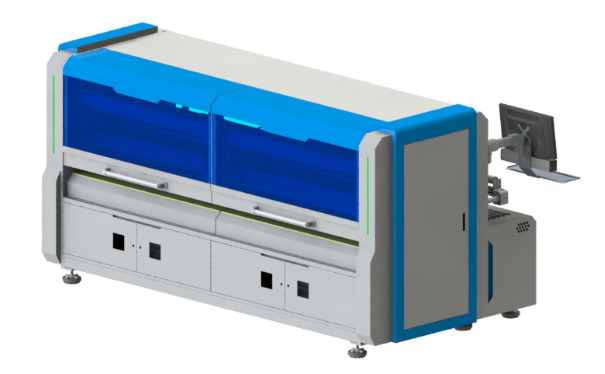

1800mm Corrugated Cardboard Carton Cutting Machine(MAC-H4-18)

In the field of custom cabinetry packaging, many factories initially only required small carton-cutting packaging lines to meet daily carton production needs. Consequently, the traditional MAC-H4A carton cutting machine (with a maximum cardboard feed width of 1600mm) became the mainstream…

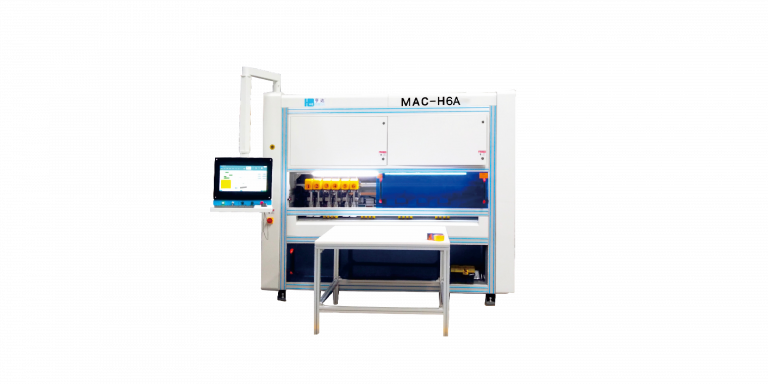

CNC Box Making Machine-Complementing Die-Cutting Machine as a Second Productivity Driver

Small orders and small batches are becoming the mainstream in the carton industry, while traditional equipment struggles to keep pace with the changes. Today’s carton industry has shifted from a “high-volume, single-specification” model to one characterized by “multiple sizes, multiple…

1 CNC Box Making Machine + 1 Digital Printing Press = The Ultimate Carton Factory Combo

The key to upgrading a carton factory lies not in “more equipments,” but in “the right equipment.” Nowadays, the cardboard box market is changing faster than it did over the past decade combined. Raw material costs are rising, competition is…

Integrating the MZH2509-D Carton Forming Machine with an Automatic Sealing Line

In the modern factory, the demand for automation, efficiency, and flexibility is greater than ever.Manufacturers are no longer satisfied with single-purpose machines — they pay attention to the packaging aspect, looking for a complete packaging line that can reduce labor…

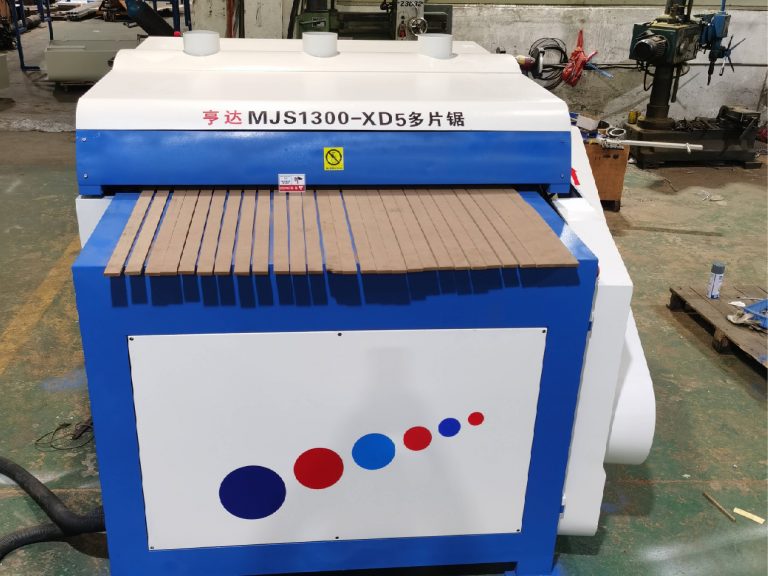

Electronic Beam Saw vs. Multi-Blade Rip Saw: Which is Right for Your Factory?

Choosing the right cutting machine is one of the most important strategic decisions for any woodworking factory. Different types of saws are designed for different production goals, and the wrong choice can lead to inefficiency, material waste, and unnecessary costs.…

Why Every Factory Needs a Box Making Machine

In today’s competitive manufacturing world, efficiency and flexibility define success. Whether you produce furniture, electronics, or e-commerce goods, packaging remains a critical yet often overlooked part of operations. Many factories are now discovering that a box making machine is not…

How to Maintain a Corrugated Cardboard Box Cutting Machine for Long-Term Efficiency

Investing in a corrugated cardboard box cutting machine is a smart move for factories looking to reduce packaging costs, improve flexibility, and produce cartons on demand. However, just like any industrial equipment, proper maintenance is essential to keep the machine…

How to Train Your Team for Safe and Efficient Gang Rip Saw Operation

Operating a gang rip saw offers incredible benefits in speed and precision, but only when your team knows how to use it properly. For woodworking factories, proper training not only prevents accidents but also maximizes output and reduces costly waste.…

Hengda Carton Cutting Machine: Enabling Flexible and Efficient Packaging Cutting

In the modern packaging industry, where product and order requirements grow increasingly diverse, the ability to efficiently and flexibly process different packaging materials through a single machine has become crucial for enhancing productivity and reducing costs. As one of the…

Hengda Carton Cutting Machine – The Intelligent Solution to Manual Packaging Challenges

In traditional packaging operations, reliance on manual carton cutting and forming presents significant pain points that directly impact production costs, product quality, and overall competitiveness. Hengda’s intelligent carton cutting machines provide a transformative solution to these persistent industry challenges. Critical…