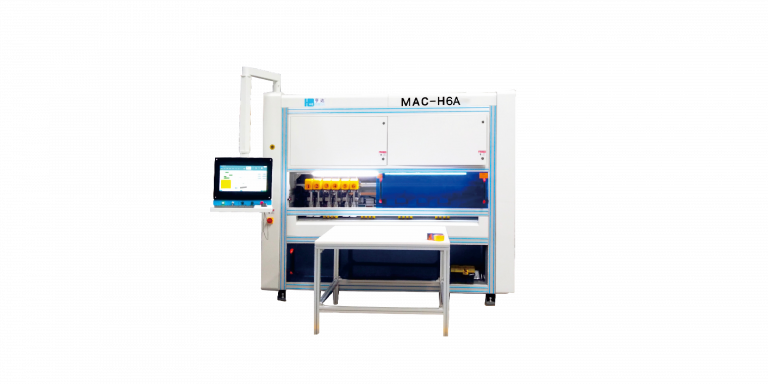

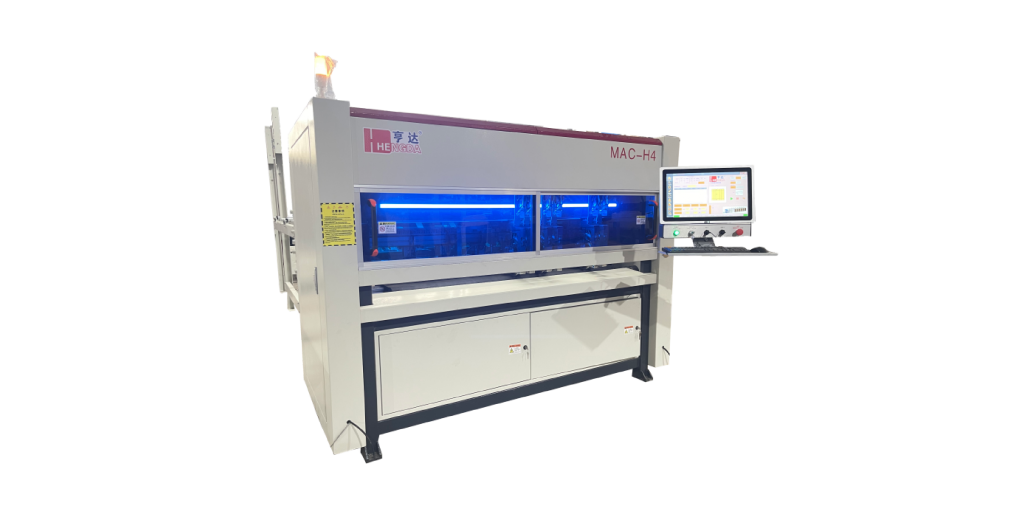

1800mm Corrugated Cardboard Carton Cutting Machine(MAC-H4-18)

In the field of custom cabinetry packaging, many factories initially only required small carton-cutting packaging lines to meet daily carton production needs. Consequently, the traditional MAC-H4A carton cutting machine (with a maximum cardboard feed width of 1600mm) became the mainstream small carton cutting machine. However, when companies sought to upgrade to a complete intelligent packaging line with carton sealing machine, the existing small carton cutting machine often encountered limitations due to insufficient unfolded width.

To address this industry pain point, Hengda introduces the all-new MAC-H4A-18 carton cutting machine—featuring a maximum cardboard feed width of 1800mm. This isn’t merely a widened model; it’s an “evolutionary device” designed based on panel dimensions, box unfolding methods, and future packaging line upgrade requirements.

The core value of the MAC-H4-18 can be summed up in one sentence: It meets your current production needs while ensuring you won’t need to replace the machine when upgrading your entire packaging line in the future.

Why Introduce The MAC-H4A-18 Carton Cutting Machine?

The origin of 1600mm: derived from the panel dimensions and the unfolded width of the middle-sealed box

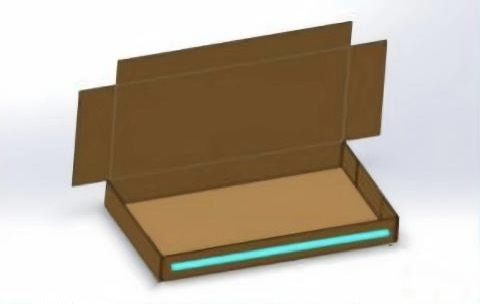

In the panel furniture industry (including custom cabinetry factories for kitchens, wardrobes, and whole-home solutions), the standard width of mainstream panels typically falls around 700mm. For conventional packaging, the FEFCO 411 middle-seal box is commonly used. Its unfolded width is calculated as:

Unfolded Width = 2W + 2H

W = Panel Width (approx. 700mm)

H = Packaging height (five 18mm panels stacked → 18*5 = 90mm, rounded to 100mm)

Substituting values: 2×700 + 2×100 = 1600mm

Therefore, MAC-HA4 can meet the demands for the traditional furniture factories.

When upgrading to whole line, the box type must be changed to 410 side sealing

When factories consider upgrading packaging lines and integrating box sealing machines, the industry imposes entirely different requirements:

Packaging lines (especially box sealing machine) must use FEFCO 410 side-sealing.

The unfolded width for side-sealing is calculated as: 2W + 3H

Substituting the same actual dimensions: 2×700 + 3×100 = 1700mm

From 1600mm → 1700mm. The existing equipment is simply not wide enough.

If you plan to integrate a carton sealing machine in the future and want to allow some margin for cardboard deviations, box height variations, or future product size adjustments, the truly reasonable figure should be: 1800mm is the stable and secure width compatible with all subsequent expansions.

This is the fundamental industry logic behind the MAC-H4-18.

The Value of MAC-H4-18 Carton Cutting Machine

Using middle-seal carton is no problem at all now, and future upgrades to side-seal carton will be fully compatible

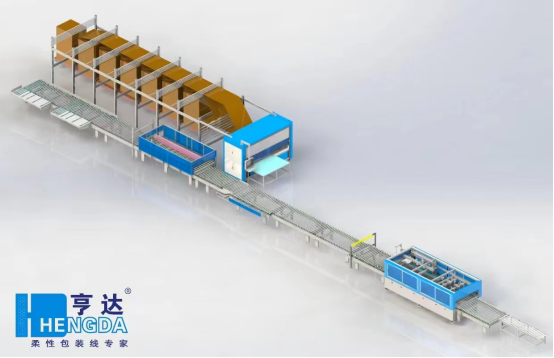

For factories with limited space and budgets, many don’t invest in a full packaging line immediately. Instead, they start with a small carton cutting machine to maintain production. Only when orders grow, production upgrades, and higher automation is needed do they add box sealing machine and full-line equipment.

The MAC-H4-18 is designed to enable you to: directly upgrade to a complete packaging line later without replacing equipment.

In other words: Buying the MAC-H4-18 = Immediate usability with future-proof scalability, eliminating the need for mid-process machine replacements or additional investments.

1800mm delivers not just width, but enhanced compatibility and greater flexibility.

The significance of 1800mm extends beyond merely “accommodating wider box types.” Its value includes:

- Supporting a broader range of panel dimensions and box configurations, no longer constrained by 1600mm

- Provides headroom for future changes in panel thickness and stacking height

- Enables seamless integration with case sealers and smart packaging lines

- Suits factories planning expansion, preventing equipment limitations from hindering upgrades

For any furniture factory with future growth plans, this is a choice that must be made correctly from the very beginning.

Conclusion

The 1800mm carton cutting machine MAC-H4-18 is not simply a larger version, but rather:

An inevitable requirement derived from industry box-type logic.

It enables factories to strike the optimal balance between “current costs” and “future scalability”:

- No budget waste upfront

- No specification constraints later

- Natively compatible with smart packaging lines

- Maximum long-term return on investment

If you’re planning carton cutting machine procurement, packaging line upgrades, or concerned about future expansion being constrained by equipment limitations, the MAC-H4-18 is the model most worthy of your priority consideration.

FAQ

What are the main differences between the MAC-H4-18 and MAC-H4A model?

The key difference is the maximum cardboard feed width, which has been increased from 1600mm to 1800mm—a necessary dimension for future packaging line upgrades.

Will MAC-HA4-18 increase material waste?

No. The width is merely the machine’s maximum capability. The actual cutting width is still set according to your carton dimensions and does not affect material utilization.

Can the MAC-H4-18 be directly integrated into the packaging line?

Yes. All our models can seamlessly connect to equipment such as carton sealing machines and measuring machines and so on.

Doesn’t the carton cutting machine have a function to switch between vertical and horizontal box cutting? Why would you need to widen the machine for adjustment?

Yes, our carton cutting machine features a longitudinal/crosswise carton output switching function. When cartons are output longitudinally, it operates flawlessly as a standalone machine. However, when integrated with a carton sealer, the longitudinal output yields suboptimal results.