CNC Box Making Machine-Complementing Die-Cutting Machine as a Second Productivity Driver

Small orders and small batches are becoming the mainstream in the carton industry, while traditional equipment struggles to keep pace with the changes. Today’s carton industry has shifted from a “high-volume, single-specification” model to one characterized by “multiple sizes, multiple batches, multiple SKUs, and small quantities.” Customers in logistics, e-commerce, furniture, cross-border trade, and other industries increasingly demand flexible packaging solutions. They often require only dozens or hundreds of boxes, with frequent size variations. Die-cutting machines remain irreplaceable for mass production, but when handling scattered orders or small batches, they require frequent mold changes, adjustments, and test cuts. This significantly impacts efficiency and makes cost control difficult. To adapt to these market shifts, carton manufacturers need efficient equipment specifically designed for scattered, urgent, and short-run orders. Against this backdrop, CNC box making machines have emerged as a crucial component of the new generation of carton production capacity.

Scattered Orders & Small Batches Have Become The Trend

Traditional die-cutting machines are not suitable for frequent order switching

Die-cutting machines achieve exceptional efficiency in mass production because their press-mode structure maintains high-speed, stable rhythms over extended periods. However, in small-batch orders, the inherent workflow—die changes, pressure adjustments, positioning calibration, and test cuts—is significantly amplified. Each order change requires recalibrating the equipment, consuming substantial time and labor. Even experienced technicians struggle to maintain optimal efficiency amid frequent changes. More critically, small-batch orders often fail to amortize tooling costs, making production increasingly inefficient as order volumes shrink. This ultimately forces many carton manufacturers to selectively accept or reject orders. This is not a flaw of the die-cutting machine itself, but rather a fundamental mismatch between order structures and equipment principles: die-cutting machines are inherently designed for high-volume production, not frequent switching between small batches.

CNC box making machines designed for short-run orders, Rush Orders

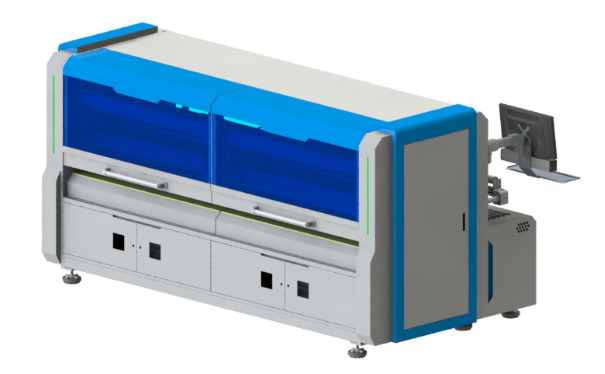

The greatest advantage of CNC box making machines lies in the flexibility and stability afforded by their digital control. All modules—including slotting, creasing, cutting, longitudinal slitting, perforating, and punching—are automatically positioned via servo systems, eliminating the need for molds, blade adjustments, or reliance on manual expertise. Operators simply input dimensions or select box types, and the machine completes adjustments within seconds to begin producing the next batch. This reduces changeover time from the traditional 10+ minutes to approximately 3 seconds. Such efficiency enables carton factories to seamlessly process dozens of different sizes daily without downtime or specialized technicians, transforming small orders from “hassles” into genuinely “high-profit opportunities.”

Comparison of CNC Box Making Machines and Die-Cutting Machines

The overall efficiency of CNC box making machines rivals that of die-cutting machines

Die-cutting machines indeed deliver long-term stable efficiency in high-volume continuous production, but their average production speed typically hovers around 400 sheets per hour. The structural characteristics of CNC carton presses inherently enable them to maintain a higher continuous operation pace under identical production conditions, achieving an actual output capacity of approximately 600 sheets per hour. This fully equips them for medium-batch production. This indicates that CNC corrugated box making machines are not solely suited for single orders or small batches; they also offer a distinct speed advantage in standard batch production. When factories need to handle different order types simultaneously, die-cutting machines can focus on high-volume orders while CNC corrugated box making machines manage medium-volume production and frequently changing specifications. This creates a more balanced and efficient production structure, keeping the entire factory’s capacity at optimal levels.

CNC box making machines are significantly safer than die-cutting machines

As a traditional heavy-duty press machine, the structure of the die-cutting machine inherently carries certain operational risks. Workers must enter the die-cutting area for loading, unloading, and adjustments. The high-pressure action is instantaneous, and improper operation can lead to severe workplace injuries—a long-standing hazard faced by many carton factories. The design philosophy of CNC box making machines is fundamentally different. They employ automatic paper feeding and fully enclosed processing structures, with all cutting actions completed within a sealed blade system. Workers never need to approach hazardous areas throughout the entire process. Servo control ensures every action is executed in a controllable and visible manner, enhancing safety through the equipment’s structural design rather than relying on operator experience. This intrinsic improvement significantly reduces the complexity of safety management for carton factories while minimizing the uncontrollable costs associated with workplace injuries.

The relationship between them is not replacement, but rather complementary

Die-cutting machines remain indispensable core equipment for large-volume orders, while CNC box making machines perfectly address their limitations in handling individual orders, small batches, and multi-model production. This enables carton factories to implement categorized production, preventing disruptions like large orders crowding out small ones or small orders delaying large ones. By adopting the structural combination of “die-cutting machines for large orders + CNC box making machines for small orders,” factories not only achieve clearer production rhythms and higher capacity utilization but also simultaneously boost profit margins and customer satisfaction. This approach maintains superior service capabilities for both major and minor clients. It represents a method of enhancing the overall business structure rather than a simple substitution between equipment types.

Conclusion

Short-run orders, small batches, and multiple shapes have become the new normal in the carton industry, yet traditional die-cutting machines struggle to efficiently handle this order structure. CNC box making machines enable carton factories to confidently meet increasingly fragmented market demands through digital control, rapid job changeovers, high safety standards, and a complementary production model with die-cutting machines. This approach boosts capacity utilization, reduces labor and safety costs, and secures more high-profit orders. Die-cutting machines remain the backbone of high-volume production, but CNC box making machines are emerging as the new “second main production line” for carton factories. In the future, a stable, efficient, and competitive carton factory will need to possess both of these critical pieces of equipment.

FAQ

Can CNC box making machines really achieve 600 boxes per hour?

Yes, this has been verified through testing in actual production, with particularly noticeable advantages when continuously processing batches of smaller-sized cartons.

Why are die-cutting machines still irreplaceable?

Die-cutting machines are highly efficient in large-volume, standardized orders, offering low costs and strong stability. They remain the core equipment in carton factories.

How do these two machines work together?

The die-cutting machine handles high-volume main production, while the CNC box making machine manages individual orders, small batches, and rush orders, creating a perfect complement.

Does a CNC box making machine require skilled technicians?

No need. Regular workers can operate it directly from the control panel.

Can you really make money with short-run orders and small batches?

Under the digital production model of CNC box making machines, individual orders no longer require mold adjustments, eliminating wasted manpower and time, thereby yielding higher profits.