How Smart Box Making Machine Turns Small Orders Into Big Profits

In traditional packaging production, small orders have always been a headache. They take up valuable time, require frequent setup changes, and generate higher costs per box. For many factories, short runs meant low efficiency and low margins.

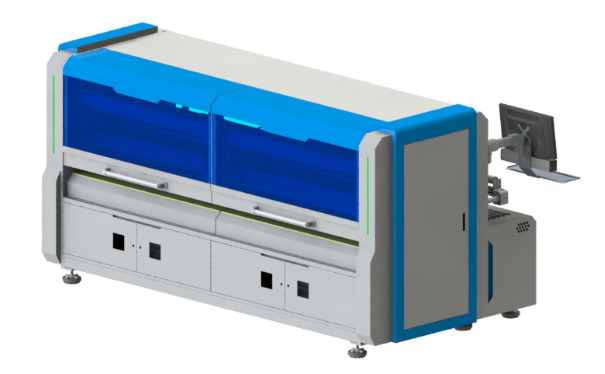

But with the arrival of smart box making machines like the HD2508-U flexible corrugated box maker, that story is changing fast. What used to be “unprofitable small batches” is now becoming a high-margin business opportunity.

Today, more manufacturers are realizing that short-run orders are not a burden—they are a gateway to new customers, faster response times, and more sustainable production.

The Problem: When Small Orders Slow Down Big Operations

For decades, box factories were built around mass production. Once a die was made, the same box ran for hours or even days.

However, today’s customers—especially those in furniture manufacturing, e-commerce, and logistics—demand fast, customized, and small-quantity packaging.

That creates a serious problem:

- Each new box size requires a new cutting die.

- Setup and calibration can take hours.

- Material waste increases during adjustment.

For many factories, these issues make small orders unprofitable. Rejecting them, however, means losing market opportunities. This is the challenge the HD2508-U smart box making machine is designed to solve.

The Solution: On-Demand Box Making Machine

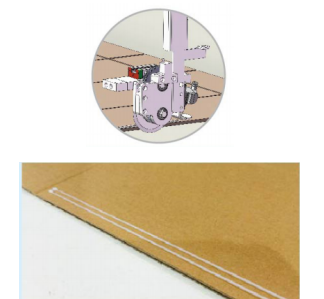

The HD2508-U Smart Corrugated Carton Box Making Machine represents a new generation of digital, die-free production technology. Instead of relying on traditional molds, the machine uses servo-controlled knives, creasing wheels, and software-based templates to automatically configure each job.

Every cutting path and pressure adjustment is generated instantly by the control software. Operators can select from over 100 built-in box styles or create new designs with custom dimensions.

The machine then automatically repositions its tools, preparing for the next job in as little as three seconds. No downtime, no wasted material—just continuous, flexible, and precise carton production.

With support for both corrugated (1.5–12 mm) and honeycomb board (1.5–25 mm), the HD2508-U adapts to everything from lightweight e-commerce boxes to heavy-duty protective packaging.

How Box Maker Turns Small Orders Into Big Profits

No Tooling Costs

Traditional die cutting requires a new cutting die for every box style—a process that costs both money and time. By removing the need for dies entirely, the HD2508-U lets manufacturers accept any quantity of orders, even a single box, without worrying about tool costs. Every small order becomes profitable because there’s no setup overhead to recover.

Time Becomes Production Capacity

Time is the most valuable asset on any production floor. With instant job changeovers, the HD2508-U turns previously wasted setup hours into active production time. This allows factories to handle more jobs per day, improve machine utilization, and shorten delivery schedules—all of which directly increase profit margins.

Reduced Waste and Higher Precision

Every cut and crease is accurate within fractions of a millimeter and there’s no manual error or board misalignment, so material waste is drastically reduced. In addition, right-sized boxes minimize void space in packaging, cutting shipping costs and contributing to more sustainable operations.

Faster ROI and Scalable Growth

Factories that once viewed small orders as unprofitable can now turn them into fast-moving, high-frequency business. By cutting overhead, setup time, and material waste, the HD2508-U often pays for itself quickly—especially in industries with frequent order changes.

Conclusion

In an industry where every minute of downtime costs money, flexibility has become the new productivity. The HD2508-U smart carton cutting machine allows packaging factories to accept any order size, meet custom demands instantly, and maintain full efficiency. It transforms packaging from a fixed, batch-based process into a true on-demand manufacturing model.

The HD2508-U Flexible Corrugated Carton Box Making Machine is more than a machine—it’s a strategy for the modern packaging era. It helps manufacturers stay competitive by combining digital control, high precision, and short-run flexibility into one system.

As demand for customization continues to rise, businesses that can handle multiple SKUs, quick changeovers, and smaller batches will win. And with the HD2508-U box making machine, they’ll not only keep up—but turn flexibility itself into profit.