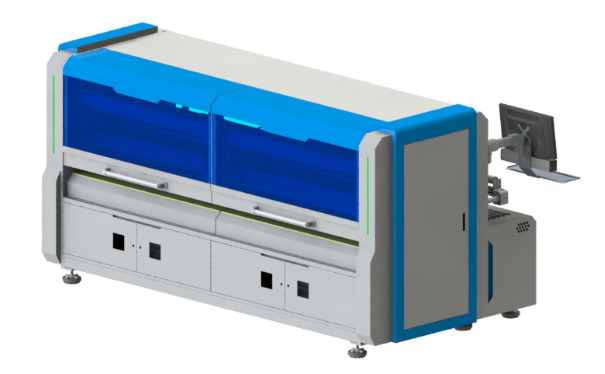

Flexible Corrugated Carton Box Making Machine for Multiple Short-Run Orders

In today’s fast-changing packaging industry, manufacturers are increasingly confronted with the need for short-run, custom-sized, multi-model orders rather than large constant batches. Traditional carton production lines, which rely on molds, manual setup changes and long change-over times, often become a bottleneck when dealing with high SKU variability or one-off packaging demands. Here, the HD2508-U Flexible Corrugated Carton Box Making Machine steps in as a leading smart solution to empower packaging factories, furniture manufacturers, and e-commerce fulfilment centres to respond quickly, flexibly and cost-effectively.

What Box Making Machine Brings to Your Workflow

The HD2508-U box making machine integrates feeding, slotting, creasing, cutting and punching into a single automated process — no cutting dies required, no lengthy manual adjustments. According to Hengda’s data, it supports a built-in library of over 100 standard box styles plus free editing of custom box types. Meanwhile, Hengda’s specification for its “on-demand” box-making machines confirms that modern flexible machines can switch jobs in 1-3 seconds, accommodate different sizes, and are operated by one person.

As such, whether you are producing cartons for cabinets, wardrobes, e-commerce parcels or protective packaging for logistics, the HD2508-U box making machine addresses the critical pain-points of:

- fast changeover between box types;

- minimal moulding setup costs;

- efficient handling of diverse small batch orders;

- custom sizing without long lead times.

Technical Highlights of Box Making Machine

- Feeding width: up to 2 ,500 mm; feeding length: 650 mm to unlimited.

- Supports corrugated board thickness of 1.5–12 mm and honeycomb board up to 1.5–25 mm.

- Processing efficiency: approximately 350-500 pcs/hour.

- Jobs can be switched in “just seconds” thanks to built-in box-style database and auto knife arrangement.

- Structure: heavy-duty national-standard profiles, ageing vibration and annealing treatment, to ensure frame stability and machining accuracy.

- Safety: enclosed protective guards with automatic power-cut when opened.

Why It Stands Out for Short-Run Orders

The HD2508-U flexible corrugated box making machine is purpose-built for the realities of modern manufacturing — where short runs, frequent changeovers, and customized sizes have become normal. Unlike traditional carton machine that needs a new die or lengthy manual setup each time the order changes, this digital system allows operators to switch from one box style to another in just a few seconds.

This makes it an ideal solution for businesses that handle multi-SKU production, custom packaging, or on-demand orders. Whether you are a furniture factory producing various cabinet sizes, a packaging converter dealing with small OEM batches, or an e-commerce warehouse customizing boxes for different products, the HD2508-U box making machine helps you respond quickly to every order without downtime.

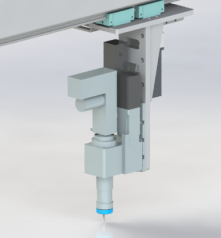

What really sets it apart is its digital control platform. Each tool—including the slotting blades, creasing wheels, and cutting knives—is servo-driven and automatically positioned by software. Operators can load box dimensions from a built-in library of more than 100 box types or import parameters from spreadsheets. The entire cutting path and creasing layout are auto-calculated, saving hours of preparation time.

It also supports corrugated and honeycomb boards from 1.5 mm to 25 mm, meaning you can produce both lightweight shipping boxes and heavy-duty industrial cartons on one machine. For manufacturers who once needed multiple machines to cover these formats, the HD2508-U brings them all together in one flexible, smart system.

In short, this model transforms short-run production from a cost burden into a competitive advantage—letting you accept any quantity, any size, at any time.

Practical Benefits You’ll See From The Box Making Machine

Upgrading to the HD2508-U box making machine offers tangible, measurable benefits across production efficiency, cost, and flexibility:

Zero Die Cost, Zero Waiting Time

Traditional box machines require a new cutting die for each box size. The HD2508-U box making machine eliminates this entirely with its digital knife system. That means no tooling expense, no outsourcing delays, and no storage of bulky dies.

Rapid Order Changeovers

Job switching is almost instantaneous. Input new box dimensions or select a saved design, and the knives reposition automatically. Production restarts within seconds—ideal for factories managing dozens of different box styles in one day.

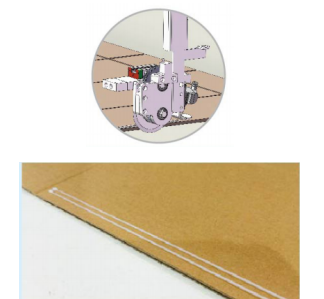

High Precision and Consistency

Servo-driven knives and a vibration cutting system ensure clean, accurate cuts even on thick honeycomb boards. Every edge aligns perfectly, maintaining consistent quality across small batches or prototypes.

Material Savings and Sustainability

Producing right-sized cartons reduces wasted board and eliminates excessive packaging space. Many users find they save 10–20% in material usage while improving packaging appearance.

Versatility Across Applications

From flat-panel furniture and kitchen cabinets to e-commerce parcels and appliance packaging, one machine can serve multiple industries. Optional modules—such as cold glue box forming or flexo printing—extend its functionality even further.

In essence, this is more than a carton cutter—it’s a complete on-demand box making machine that delivers flexibility, reliability, and measurable ROI for every short-run packaging business.

Conclusion

In a market where customisation, small-batch production, and rapid turnaround are rapidly becoming the norm rather than the exception, the HD2508-U Flexible Corrugated Carton Box Making Machine offers a smart, automated, high-precision answer. It redefines how packaging factories and furniture or e-commerce manufacturers address the challenge of multiple, variable orders — delivering capability, flexibility and cost-efficiency in one integrated system.