Boost Packaging Efficiency with the MZH2509-D Flexible Carton Forming Machine

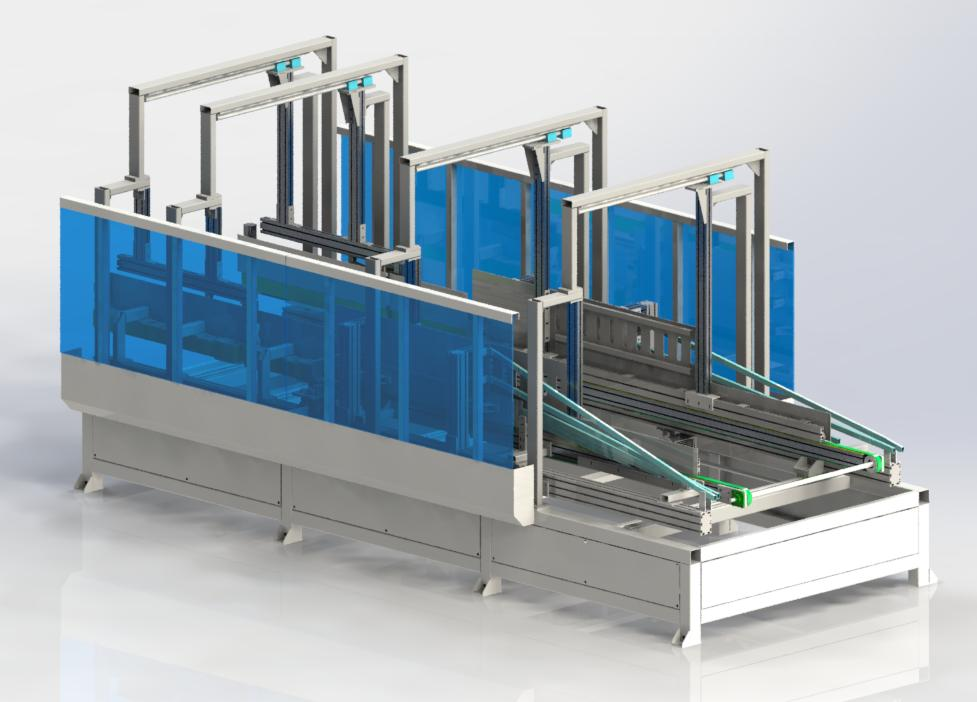

In modern factory, for the aspect of packaging production, efficiency, flexibility, and quality determine competitiveness. The MZH2509-D Flexible Carton Forming Machine from Hengda is designed to help manufacturers meet these goals — offering fully automated bottom box forming for single-cover (410) and top-bottom lid cartons (0300) with precision and speed.

What Is the MZH2509-D Flexible Carton Forming Machine?

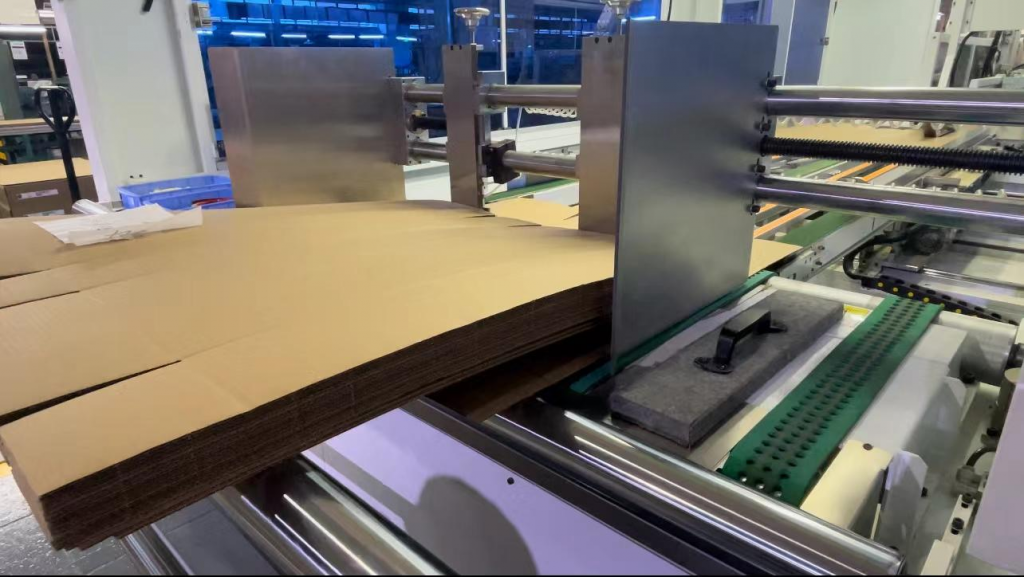

The MZH2509-D is an automatic carton folding and forming machine developed for 0410 and 0300 box types, that is side-seal box and sky-and-earth lid box. It automatically folds, glues, and presses the four corners of corrugated sheets using EVA hot melt adhesive, forming strong and neatly shaped carton bases. Unlike manual folding, this system can operate continuously, achieving 5–10 times higher productivity while ensuring consistency across every box.

Key Features and Advantages

Automatic Feeding & Positioning

The machine is equipped with an automatic feeding unit that allows multiple corrugated sheets to be stacked and fed automatically. Its auto-correction mechanism ensures precise alignment before folding, improving accuracy and reducing waste.

High-Speed Servo Adjustment

With servo-controlled width positioning, the MZH2509-D supports fast size changeovers for various carton specifications — ideal for short-run or customized packaging orders.

EVA Hot Melt Gluing Technology

The machine uses EVA hot melt glue, which offers stronger adhesion and better sealing performance compared to traditional methods. It’s clean, environmentally friendly, and produces smooth, firm box bases.

Integrated Folding and Forming Design

All folding, gluing, and pressing operations are completed within a single unit, giving each carton a consistent cube-like shape with high visual quality.

Flexible Integration

The MZH2509-D can work as a standalone forming unit or be connected to an automatic carton sealing machine to create a complete carton forming and sealing line for automated packaging.

Why Choose a Flexible Carton Forming Solution?

Traditional manual carton folding is slow, inconsistent, and labor-intensive.

The MZH2509-D Flexible Carton Forming Machine helps manufacturers:

- Save labor costs — requiring only 1–2 operators

- Maintain consistent quality — every carton base is accurately glued

- Handle multiple box sizes easily — thanks to servo-driven adjustments

- Increase output efficiency — suitable for continuous 24-hour operation

This makes it the perfect solution for packaging companies that deal with frequent order changes, small-batch runs, or customized box designs.

Ideal Applications

The MZH2509-D is widely used in industries such as:

- Furniture and home appliances packaging

- E-commerce and logistics packaging

- Bathroom vanity products

- All kind of products packed by Fefco410 boxes

Conclusion

If your production line requires efficient bottom box forming with strong adhesive bonding and high precision, the MZH2509-D Automatic Flexible Carton Forming Machine is the ideal choice.

It helps your business streamline operations, reduce costs, and upgrade to intelligent packaging automation.