MZH2510 Flexible Carton Folding Machine for Bottom Box Forming and Packaging Line

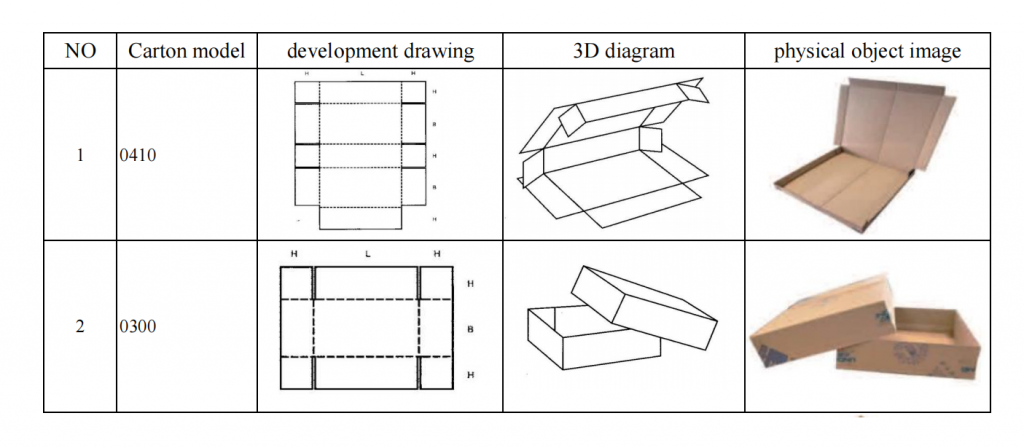

The MZH2510 Flexible Carton Folding Machine is designed for forming the bottom of single-cover cartons and top-and-bottom lid boxes. It uses a EVA hot melt adhesive system to automatically fold and glue the four corners of corrugated sheets, creating firm and neat box bottoms.

This machine is ideal for short-run or customized packaging production, and can be seamlessly combined with an automatic carton sealing machine to form a carton forming and sealing line. It helps manufacturers improve efficiency, reduce labor costs, and achieve consistent packaging quality.